Abstract

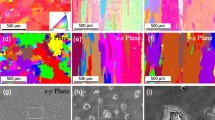

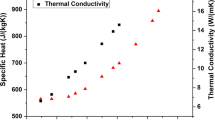

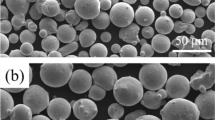

The anisotropy in tensile properties of Wire Laser Metal Deposited Inconel 718 (LMD-w) has been investigated from room temperature up to 750 °C at a strain rate of 5.0 10–4 s−1. These properties have been investigated along, at 45° and perpendicular to the building direction. Moreover, different heat treatments have been used: as-built, solution heat treated to dissolve Laves phases, solution treated + aged to trigger γ′/γ″ precipitation and direct-aged. According to this extensive characterization of tensile properties, complemented by SEM and EBSD characterizations, it is shown that, whatever the temperature, Yield stress and tensile resistance have a very weak anisotropy and that tensile properties are mostly dependent to the prior heat treatment state. The anisotropy is mostly observed on elastic properties, due to a pronounced crystallographic texture inherited from the directional thermal gradient during the building process. Moreover, Laves phases do not seem to have a strong impact on tensile properties for this coarse grain material. Tensile strength in such an LMD-processed Inconel 718 is mostly controlled by the γ′/γ″ precipitation and stored “processing” dislocations. A loss of tensile ductility has been evidenced at 750 °C, due to grain boundary oxidation.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Loria, E.A., Recent developments in the progress of superalloy 718. JOM, 1992. 44(6): p. 33–36.

Longuet, A., C. Dumont, and E. Georges, Advanced modeling tools for processing and lifing of aeroengine components, in Superalloys 2020. 2020, Springer. p. 3–15.

Alizadeh-Sh, M., et al., Prediction of solidification cracking by an empirical-statistical analysis for laser cladding of Inconel 718 powder on a non-weldable substrate. Optics & Laser Technology, 2020. 128: p. 106244.

Galliano, F., et al., Effect of temperature on hydrogen embrittlement susceptibility of alloy 718 in Light Water Reactor environment. International Journal of Hydrogen Energy, 2017. 42(33): p. 21371–21378.

Valle, L., et al., The influence of heat treatments on the corrosion behaviour of nickel-based alloy 718. Journal of Alloys and Compounds, 2019. 809: p. 151781.

Donachie, M.J. and S.J. Donachie, Superalloys: a technical guide. 2002: ASM international.

Nicolaÿ, A., et al. Metallurgical Analysis of Direct Aging Effect on Tensile and Creep Properties In Inconel 718 Forgings. in Superalloys 2020. 2020. Seven Springs, PA, USA: TMS.

Texier, D., et al., Microstructural features controlling the variability in low cycle fatigue properties of alloy Inconel 718DA at intermediate temperature. Metallurgical and Materials Transactions A, 2016. 47A: p. 1096–1109.

Texier, D., et al., Crack initiation sensitivity of wrought direct aged alloy 718 in the very high cycle fatigue regime: the role of non-metallic inclusions. Material Science and Engineering A, 2016. 678: p. 122–136.

Texier, D., et al. Role of Non-metallic Inclusions and Twins on the Variability in Fatigue Life in Alloy 718 Nickel Base Superalloy. in Superalloys 2020. 2020. Seven Springs, PA, USA: TMS.

Texier, D., et al., Short crack propagation from cracked non-metallic inclusions in a Ni-based polycrystalline superalloy. Acta Materialia, 2019. 165: p. 241–258.

Lippold, J.C., S.D. Kiser, and J.N. DuPont, Welding metallurgy and weldability of nickel-base alloys. 2011: John Wiley & Sons.

Andersson, J., Weldability of precipitation hardening superalloys: influence of microstructure, PhD Thesis, 2011, Chalmers University (Sweden).

CFM International, https://www.cfmaeroengines.com/services/maintenance/. 2022.

Onuike, B. and A. Bandyopadhyay, Additive manufacturing in repair: Influence of processing parameters on properties of Inconel 718. Materials Letters, 2019. 252: p. 256-259.

Saboori, A., et al., Application of directed energy deposition-based additive manufacturing in repair. Applied Sciences, 2019. 9(16): p. 3316.

Hosseini, E. and V. Popovich,A review of mechanical properties of additively manufactured Inconel 718. Additive Manufacturing, 2019. 30: p. 100877.

Adomako, N.K., N. Haghdadi, and S. Primig, Electron and laser-based additive manufacturing of Ni-based superalloys: a review of heterogeneities in microstructure and mechanical properties. Materials & Design, 2022: p. 111245.

Kumar, S.P., et al.,A review on properties of Inconel 625 and Inconel 718 fabricated using direct energy deposition. Materials Today: Proceedings, 2021. 46: p. 7892–7906.

Heckert, S. and B. Wedel. Laser processing heads for cladding and heat treatment applications. in the 2nd Annual Laser Additive Manufacturing Workshop (LAM 2010), Houston, TX, USA (Laser Institute of America, Orlando, FL, USA, 2010). 2010.

Vaunois, J.R., et al. Influence of both γ′ distribution and grain size on the tensile properties of UDIMET 720Li at room temperature. in 7th International Symposium on Superalloy 718 and Derivatives. 2010. Pittsburgh, PA, USA: TMS.

Mataveli Suave, L., et al., Anisotropy in creep properties of DS200 + Hf alloy. Materials at High Temperatures, 2016. 33(4–5): p. 361–371.

Mataveli Suave, L., et al. High temperature creep damage mechanisms in a directionally solidified alloy: impact of crystallography and environment. in Superalloys 2016. 2016. Seven Springs, Champion, PA, USA: TMS.

Mataveli Suave, L., et al., Thin-wall debit in creep of DS200+Hf alloy. Metallurgical and Materials Transactions A, 2018. 49A: p. 4012–4028.

Radhakrishna, C. and K. Prasad Rao, The formation and control of Laves phase in superalloy 718 welds. Journal of Materials Science, 1997. 32(8): p. 1977–1984.

Seow, C.E., et al., Wire+ Arc Additively Manufactured Inconel 718: Effect of post-deposition heat treatments on microstructure and tensile properties. Materials & Design, 2019. 183: p. 108157.

You, X., et al., Effect of solution heat treatment on the precipitation behavior and strengthening mechanisms of electron beam smelted Inconel 718 superalloy. Materials Science and Engineering: A, 2017. 689: p. 257–268.

Torfeh, M. et al., Intermediate Temperature Creep Damage Mechanisms of a Directionally Solidified Ni-Based Superalloy. Materials at High Temperatures, 2022. 39(3): p. 193–205.

Stinville, J.C., et al., Damage Nucleation During Transverse Creep of a Directionally Solidified Ni-based Superalloy. Material Science & Engineering A, 2022. 858: p. 144089.

Chaturvedi, M. and Y.-f. Han, Strengthening mechanisms in Inconel 718 superalloy. Metal science, 1983. 17(3): p. 145–149.

Cozar, R. and A. Pineau, Morphology of γ′ and γ″ precipitates and thermal stability of inconel 718 type alloys. Metallurgical Transactions, 1973. 4(1): p. 47–59.

Paulonis, D., J. Oblak, and D. Duvall, Precipitation in Nickel-base Alloy 718. 1969, Pratt and Whitney Aircraft, Middletown, Conn.

Mataveli Suave, L., et al., High temperature low cycle fatigue properties of Alloy 625. Materials Science and Engineering A, 2016. 650: p. 161–170.

Mataveli Suave, L., et al., Microstructural evolutions during thermal aging of Alloy 625: impact of temperature and forming process. Metallurgical and Materials Transactions A, 2014. 45A(7): p. 2963–2982.

Fedelich, B., Crystal orientation and elastic properties, in Nickel base single Crystals across length scales. 2022, Elsevier. p. 41–67.

Gadaud, P., Crystal Elasticity. 2022: John Wiley & Sons.

Cormier, J., et al., In-Situ Determination of Precipitation Kinetics during Heat Treatment of Superalloy 718. Metallurgical and Materials Transactions A, 2021. 52A(2): p. 500–511.

Ho, I.-T., et al.,Effects of CoAl2O4 inoculants on microstructure and mechanical properties of IN718 processed by selective laser melting. Additive Manufacturing, 2020. 35: p. 101328.

Hsu, T.-H., et al., Effect of Carbide Inoculants Additions in IN718 Fabricated by Selective Laser Melting Process, in Superalloys 2020. 2020, Springer. p. 982–989.

Cabeza, S., et al. Strain Monitoring of Laser Metal Deposition of Inconel 718 by Neutron Diffraction. in Superalloys 2020. 2020. Seven Springs, PA, USA: TMS.

Nicolaÿ, A., Microstructure et propriétés de l'Inconel 718 DA forgé en presse à vis dans le domaine subsolvus δ, PhD thesis, 2019, Mines ParisTech: Sophia Antipolis, France.

Deng, D., et al., Microstructure and mechanical properties of Inconel 718 produced by selective laser melting: Sample orientation dependence and effects of post heat treatments. Materials Science and Engineering: A, 2018. 713: p. 294–306.

Liu, S., et al.,The effect of energy density on texture and mechanical anisotropy in selective laser melted Inconel 718. Materials & Design, 2020. 191: p. 108642.

Bean, G., et al., Build orientation effects on texture and mechanical properties of selective laser melting Inconel 718. Journal of Materials Engineering and Performance, 2019. 28(4): p. 1942–1949.

Sazerat, M., et al. Microstructural and tensile properties evolutions of direct-aged Waspaloy produced by Wire Arc Additive Manufacturing in 10th International Symposium on Superalloy 718 and Derivatives. 2023. Pittsburgh, PA, USA: TMS.

Kubin, L., B. Lisiecki, and P. Caron, Octahedral slip instabilities in γ/γ′ superalloy single crystals CMSX-2 and AM3. Philosophical Magazine A, 1995. 71(5): p. 991–1009.

MacKay, R.A. and R.D. Maier, The influence of orientation on the stress rupture properties of nickel-base superalloy single crystals. Metallurgical Transactions A, 1982. 13(10): p. 1747–1754.

Stinville, J., K. Gallup, and T. Pollock, Transverse creep of nickel-base superalloy bicrystals. Metallurgical and Materials Transactions A, 2015. 46(6): p. 2516–2529.

Agnoli, A., et al., Mechanical properties evolution of γ′/γ″nickel-base superalloys during long term thermal over-aging. Metallurgical and Materials Transactions A, 2018. 49A: p. 4290–4300.

Jouiad, M., et al., Microstructure and mechanical properties evolutions of Alloy 718 during isothermal and thermal cycling over-aging. Materials & Design, 2016. 102: p. 284–296.

Slama, C., C. Servant, and G. Cizeron, Aging of the Inconel 718 alloy between 500 and 750 C. Journal of materials research, 1997. 12(9): p. 2298–2316.

Balan, A., et al., Precipitation of γ'’ in Inconel 718 alloy from microstructure to mechanical properties. Materialia, 2021. 20: p. 101187.

Rezende, M.C., et al., Oxidation assisted intergranular cracking under loading at dynamic strain aging temperatures in Inconel 718 superalloy. Journal of alloys and compounds, 2015. 643: p. S256–S259.

Wagenhuber, E., V. Trindade, and U. Krupp. The role of oxygen-grain-boundary diffusion during intercrystalline oxidation and intergranular fatigue crack propagation in alloy 718. in Proc. Int. Symp. Superalloys Var. Deriv. Pittsburgh, PA. 2005.

Thébaud, L., et al. Relationships between microstructural paramaters and time-dependent mechanical properties of a new nickel based superalloy AD730TM. in Superalloys 2016. 2016. Seven Springs, Champion, PA, USA: TMS.

Gabb, T.P., et al. Use of Slow Strain Rate Tensile Testing to Assess the Ability of Several Superalloys to Resist Environmentally‐Assisted Intergranular Cracking. in 8th International Symposium on Superalloy 718 and Derivatives. 2014. Wiley Online Library.

Janaki Ram, G., et al., Control of Laves phase in Inconel 718 GTA welds with current pulsing. Science and technology of welding and joining, 2004. 9(5): p. 390–398.

Sui, S., et al., The influence of Laves phases on the high-cycle fatigue behavior of laser additive manufactured Inconel 718. Materials Science and Engineering: A, 2017. 695: p. 6–13.

Theska, F., et al., On conventional versus direct ageing of Alloy 718. Acta Materialia, 2018. 156: p. 116–124.

Theska, F., et al., Microstructure-property relationships in directly aged Alloy 718 turbine disks. Materials Science and Engineering: A, 2020. 776: p. 138967.

Acknowledgements

Pprime Institute gratefully acknowledges “Contrat de Plan Etat - Région Nouvelle-Aquitaine” (CPER) as well as the “Fonds Européen de Développement Régional (FEDER)” for their financial support to the reported work in the context of the OPERA program (convention P-2020-BAFE-3). This work was partially funded by the French Government program “Investissements d’Avenir” (EQUIPEX GAP, reference ANR-11-EQPX-0018).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Cormier, J. et al. (2023). Tensile Properties of Inconel 718 Produced by LMD-Wire. In: Ott, E.A., et al. Proceedings of the 10th International Symposium on Superalloy 718 and Derivatives. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-27447-3_42

Download citation

DOI: https://doi.org/10.1007/978-3-031-27447-3_42

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-27446-6

Online ISBN: 978-3-031-27447-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)