Abstract

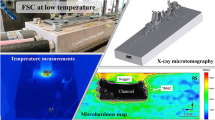

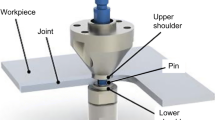

Submerged bobbin tool (SBT) tunneling is a new friction stir processing (FSP) technique for making integral channels within malleable materials. Like a conventional bobbin tool (BT) for friction stir welding (FSW), an SBT toolset has two opposing shoulders spaced apart along the bobbin or probe section of the tool. Unlike a conventional BT, an SBT is used to form integral subsurface channels by passing the shoulder at the distal end of the probe through the workpiece during processing. Example uses of internal pathways are found in heat exchangers, cooling plates, and vacuum tools. Advance uses may include lessening weight and modifying the stiffness of structural components. A preliminary evaluation in AA6061-T6511 plates shows this special form of FSP has low process forces and is therefore capable of being deployed on CNC (computer numerical control) machining centers and friction stir-capable industrial robots as well as purpose-built FSP machines. Consequently, SBT tunneling holds potential use in a wide range of applications requiring curvilinear internal pathways for wiring, gases, and fluids, as well as internal spaces for the placement of powders and solid materials like composites.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Mishra R (2004) Integral channels in metal components and fabrication thereof. US Patent Application Publication 20040060965A1. 1 April 2004

Mishra RS (2005) Integral channels in metal components and fabrication thereof. US Patent 6,923,362. 2 August 2005

Mishra RS (2008) Integral channels in metal components and fabrication thereof. US Patent 7,354,657. 8 April 2008

Ayub ZH (2003) Plate heat exchanger literature survey and new heat transfer and pressure drop correlations for refrigerant evaporators. Heat Transfer Eng 24(5):3–16. https://doi.org/10.1080/01457630304056

Miller WS, Zhuang L, Bottema J, Wittebrood AJ, De Smet P, Haszler A, Vieregge A (2000) Recent development in aluminium alloys for the automotive industry. Mater Sci Eng, A 280(1):37–49. https://doi.org/10.1016/S0921-5093(99)00653-X

Harris C (2001) Design, fabrication, and testing of cross flow micro heat exchangers. Doctor of Philosophy. Louisiana State University and Agricultural & Mechanical College. https://doi.org/10.31390/gradschool_disstheses.290

Launay S, Sartre V, Bonjour J (2007) Parametric analysis of loop heat pipe operation: a literature review. Int J Therm Sci 46(7):621–636. https://doi.org/10.1016/j.ijthermalsci.2006.11.007

Balasubramanian N, Krishnamurthy K, Mishra RS (22 May 2009) Preliminary study of pressure drop and heat transfer through a friction stir channel. ASME 2007 international mechanical engineering congress and exposition. Seattle, Washington, USA pp 933–939. https://doi.org/10.1115/IMECE2007-41634

Balasubramanian N, Mishra RS, Krishnamurthy K (2009) Friction stir channeling: Characterization of the channels. J Mater Process Technol 209(8):3696–3704. https://doi.org/10.1016/j.jmatprotec.2008.08.036

Balasubramanian N, Mishra RS, Krishnamurthy K (2010) Development of a mechanistic model for friction stir channeling. J Manuf Sci Eng 132(5):054504. https://doi.org/10.1115/1.4002453

Balasubramanian N, Mishra RS, Krishnamurthy K (2011) Process forces during friction stir channeling in an aluminum alloy. J Mater Process Technol 211(2):305–311. https://doi.org/10.1016/j.jmatprotec.2010.10.005

Pandya S, Mishra RS, Arora A (2019) Channel formation during friction stir channeling process—a material flow study using X-Ray micro-computed tomography and optical microscopy. J Manuf Process 41:48–55. https://doi.org/10.1016/j.jmapro.2019.03.021

Mehta KP, Vilaça P (2022) A review on friction stir-based channeling. Crit Rev Solid State Mater Sci 47(1):1–45. https://doi.org/10.1080/10408436.2021.1886042

Di Pietro V, Gandra J, Dodds S (3 May 2021) Thermal management of power components and electric systems using channels embedded in metallic parts by friction stir channelling. PCIM Europe digital days 2021; international exhibition and conference for power electronics, intelligent motion, renewable energy and energy management. VDE VERLAG GMBH, Berlin, Offenbach, pp 1138–1143

Di Pietro V, Gandra J, Clarke A, Hockaday J, Law R (March 2022) Removing design and manufacturing complexity from integrated thermal management solutions using friction stir channelling. presented at the 2022 38th semiconductor thermal measurement, modeling and management symposium (SEMI-THERM). San Jose, CA. https://ieeexplore.ieee.org/document/9755866

Karvinen H, Nordal D, da Silva PSV (2018) Microstructural characterization of the stir processed zones of Cu-Al and Al-Al plate systems manufactured by hybrid friction stir channeling. 12th lnternational symposium on friction stir welding. TWI Ltd. Session 7 (Techniques II). 26 June 2018. https://research.aalto.fi/en/publications/microstructural-characterization-of-the-stir-processed-zones-of-c

Karvinen H, Nordal D, Galkin T, Vilaça P (2018) Application of hybrid friction stir channeling technique to improve the cooling efficiency of electronic components. Welding World 62(3):497–509. https://doi.org/10.1007/s40194-018-0576-8

Burford DA, Mishra R (28 July 2022) Systems and methods for internal channel formation within a workpiece. US Patent Application Publication 20220234132A1

Goetze P, Kopyściański M, Hamilton C, Dymek S (12 Feb 2019) Comparison of dissimilar aluminum alloys joined by friction stir welding with conventional and bobbin tools. In: Friction stir welding and processing X, the minerals, metals and materials series. Springer, Cham pp 3–12. https://doi.org/10.1007/978-3-030-05752-7_1

Burford D (15 March 2022) Submerged bobbin tool (SBT) tunneling technology. presented at the AeroMat 2022. Pasadena, CA. https://asm.confex.com/asm/aero22/webprogram/Paper55159.html

Burford D (2022) Submerged bobbin tool (SBT) tunneling technology. presented at the AeroMat 2022: research and development enabling next-generation aerospace materials. Pasadena, CA. https://www.youtube.com/watch_popup?v=49mS2jZyAN4

Koonce JG (2022) Impact of processing parameters and forces on channels created by friction stir bobbin tools, master’s thesis. University of North Texas (UNT). https://digital.library.unt.edu/ark:/67531/metadc1944372/

Acknowledgements

Funding for the initial development phase of the SBT tunneling process was provided through the Advanced Materials & Manufacturing Processes Institute (AMMPI) located at the Discovery Park campus of the University of North Texas (UNT). The technology transfer phase conducted during the summer of 2021 was funded by a grant from AMMPI. Submerged Bobbin Tool (SBT) Tunneling Technology is a patent pending process of UNT.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Burford, D.A. et al. (2023). Submerged Bobbin Tool (SBT) Tunneling Technology. In: Hovanski, Y., Sato, Y., Upadhyay, P., Naumov, A.A., Kumar, N. (eds) Friction Stir Welding and Processing XII. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22661-8_23

Download citation

DOI: https://doi.org/10.1007/978-3-031-22661-8_23

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22660-1

Online ISBN: 978-3-031-22661-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)