Abstract

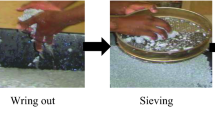

Guaruman fiber is a natural lignocellulosic fiber (NFL) extracted from the stalk of an Amazon plant (Ishinosiphon Koern) in the northern region of Brazil. The present work investigates the addition of 2.5, 5.0 and 7.5 wt.% of guaruman fiber, in cement mass, and a reference mortar (0%). The fibers were mercerized in NaOH solution for improved adhesion to a mortar matrix made with 1:1:6 ratio of Ordinary Portland Cement (OPC), lime and natural sand. Technical properties, such as density, consistency, content of air incorporated and water retention were evaluated for the processed fresh state of the mortar reinforced with guaruman fiber. The preliminary results in association with the relatively low density of the mortars incorporated with NaOH-treated guaruman fibers reveal a promising material to be applied as mortar for wall covering in civil construction, in a proportion of 7.5 wt.%, which shows a great potential for the use of this fiber.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Azevedo ARG, Alexandre J, Marvila MT, Xavier GC, Monteiro SN, Pedroti LG (2020) Technological and environmental comparative of the processing of primary sludge waste from paper industry for mortar. J Clean Prod 249:119336

Nasr MS, Shubbar AA, Abed ZAAR, Ibrahim MS (2020) Properties of eco-friendly cement mortar contained recycled materials from different sources. J Build Eng 31:101444

Azevedo ARG, Marvila MT, Tayeh BA, Cecchin D, Pereira AC, Monteiro SN (2021) Technological performance of açaí natural fibre reinforced cement-based mortars. J Build Eng 33:101675

Marvila MT, Azevedo ARG, Cecchin D, Costa JM, Xavier GC, Carmo DDF, Monteiro SN (2020) Durability of coating mortars containing açaí fibers. Case Stud Constr Mater 13:e00406

Fediuk RS, Lesovik VS, Svintsov AP, Mochalov AV, Kulichkov SV, Stoyushko NY, Timokhin RA (2018) Self-compacting concrete using pretreatmented rice husk ash. Mag Civ Eng 79(3):66–76

Zukowski B, Silva FA, Toledo Filho RD (2018) Design of strain hardening cement-based composites with alkali treated natural curaua fiber. Cem Concr Compos 89:150–159

Reis JM (2013) Fracture properties of curaua fibers reinforced polymer mortars. Adv Mater Res Trans Tech Publ Ltd 687:490–494

Fediuk R, Smoliakov A, Muraviov A (2017) Mechanical properties of fiber-reinforced concrete using composite binders. Adv Mater Sci Eng 1:1–13

Pimentel MG, Borges JPDC, Picanço MDS, Ghavami K (2016) Response to flexural and toughness analysis of mortars reinforced with curaua fiber. Matéria (Rio J) 21(1):18–26

Picanço MDS, Ghavami K (2008) Compressive behavior of mortars reinforced with Amazon vegetable fibers. REM Rev Esc De Minas 61:13–18

Seydibeyoglu MO, Mohanty AK, Misra M (2017) Natural fibers. Fiber technology for fiber-reinforced composites. Woodhead Publishing, Cambridge, pp 09–235

Reis RHM, Nunes LF, Oliveira MS, Veiga Junior VF, Garcia Filho FDC, Pinheiro MA, Monteiro SN (2020) Guaruman fiber: another possible reinforcement in composites. J Mater Res Technol 9(1):622–628

Monteiro SN, Lopes FPD, Barbosa AP, Bevitori AB, Silva ILA, Costa LL (2011) Natural lignocellulosic fibers as engineering materials—an overview. Metall Mater Trans 42(10):2963–2974

Monteiro SN, Lopes FPD, Ferreira AS, Nascimento DCO (2009) Natural-fiber polymer-matrix composites: cheaper, tougher, and environmentally friendly. Jom 61(1):17–22

Satyanarayana KG, Guimarães JL, Wypych F (2007) Studies on lignocellulosic fibers of Brazil. Part I: Source, production, morphology, properties and applications. Compos Part A Appl Sci Manuf 38(7):1694–1709

Azevedo ARG, Nascimento M, Carmo D, Marvila MT, Xavier GC, Monteiro SN (2022) Environmental and durability perspective of the use of curaua fiber treatedin mortars. J Renew Mater 10(6):1–21

Azevedo ARG, Vilumev SV, Marvila MT, Vatin NI, Alfimova NI, Lima TES, Fediur R, Olisov AV (2020) Investigation of the potential use of curaua for reinforcing mortars. Fibers 8(11):69

Soltan DG, Neves P, Olvera A, Junior HS, Li VC (2017) Introducing a curaua fiber reinforced cement-based composite with strain-hardening behavior. Ind Crops Prod 103:1–12

NBR 13276 (2016) Mortar for laying and covering walls and ceilings—determination of consistency index. Brazilian Association of Technical Standards

Lertwattanaruk P, Suntijitto A (2015) Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Constr Build Mater 94:664–669

Arce C, Garzon E, Sanchez-Soto PJ (2019) Phyllite clays as raw materials replacing cement in mortars: properties of new impermeabilizing mortars. Constr Build Mater 224:348–358

Azevedo ARG, Marvila MT, Zanelato EB, Alexandre J, Xavier GC, Cecchin D (2020) Development of mortar for laying and coating with pineapple fibers. Rev Bras De Eng Agric e Ambient 24:187–193

Azevedo ARG, Marvila MT, Barroso LS, Zanelato EB, Alexandre J, Xavier GC, Monteiro SN (2019) Effect of granite residue incorporation on the behavior of mortars. Materials 12(9):1449

Fediuk RS, Smoliakov AK, Timokhin RA, Batarshin VO, Yevdokimova YG (2017) Using thermal power plants waste for building materials. IOP Conf Ser: Earth Environ Sci 87(9):092010

Marvila MT, Azevedo ARG, Alexandre J, Vieira CMF, Zanelato EB, Delaqua GCG (2020) Study of the compressive strength of mortars as a function of material composition, workability, and specimen geometry. Model Simul Eng 4:1–6

Okada K, Ooyama A, Isobe T, Kameshima Y, Nakajima A, MacKenzie KJD (2009) Water retention properties of porous geopolymers for use in cooling applications. J Eur Ceram Soc 29(10):1917–1923

Suwan T, Maichin P, Fan M, Jitsangiam P, Tangchirapat W (2022) Influence of alkalinity on self-treatment process of natural fiber and properties of its geopolymeric composites. Constr Build Mater 316:125817

Bui H, Sebaibi N, Boutouil M, Levacher D (2020) Determination and review of physical and mechanical properties of raw and treated coconut fibers for their recycling in construction materials. Fibers 8(6):37

Wei J, Meyer C (2015) Degradation mechanisms of natural fiber in the matrix of cement composites. Cem Concr Res 73:1–16

Shi Z, Geiker MR, Weerdt K, Lothenbach B, Kaufmann J (2015) Durability of portland cement blends including calcined clay and limestone: Interactions with sulfate, chloride and carbonate ions. RILEM Book 10:133–141

Acknowledgements

The authors thank the Brazilian agencies CNPq, CAPES, and FAPERJ for the support provided to this investigation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Lima, T.E.S. et al. (2023). Study of Cement-Based Mortars Reinforced with Guaruman Fibers in the Fresh State. In: Zhang, M., et al. Characterization of Minerals, Metals, and Materials 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22576-5_57

Download citation

DOI: https://doi.org/10.1007/978-3-031-22576-5_57

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22575-8

Online ISBN: 978-3-031-22576-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)