Abstract

Waste generation and its improper disposal have been growing substantially nowadays, among them, steel wastes, ornamental stones and polymers instigating serious environmental problems. The development of artificial stones using a polymeric matrix from a renewable source is a great alternative to reincorporate these types of waste, creating a novel sustainable stone with properties that make them suitable for use as a coating in civil construction. This work’s main objective was to produce and characterize an artificial stone (ASGS) with 85% of wastes (granite and steel) in a 15% vegetable polyurethane matrix. Initially, the most close-packed granulometric composition was determined, followed by the plates production using vibration, compression, and vacuum. ASGS presented 2.24 g/cm3 density, which was within the expected range, 0.46% of water absorption, which was at the limit to be considered a low water absorption stone and 1.04% of apparent porosity, denoting its high porosity content. The ASGS bend strength classified it as a stone of very high mechanical strength. Through SEM micrographs, the high content of apparent porosity was confirmed, and a low load/matrix interaction was verified. However, analyzing the ASGS bend strength, it was possible to conclude that it did not impair its mechanical strength.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Das O, Babu K, Shanmugam V, Sykam K, Tebyetekerwa M, Neisiany RE, Forsth M, Sas G, Libreros JG, Capezza AJ, Hedenqvist MS, Berto F, Ramakrishna S (2022) Natural and industrial wastes for sustainable and renewable polymer composites. Renew Sustain Energy Rev. https://doi.org/10.1016/j.rser.2021.112054

Arumugaprabu V, Johnson RDJ, Vigneshwaran S (2020) Mechanical performance of nanocomposites and biomass-based composite materials and its applications: an overview. In: Handbook of nanomaterials and nanocomposites for energy and environmental applications. Cham: Springer International Publishing. pp. 1–14. https://doi.org/10.1007/978-3-030-11155-7_123-1

Mosaferi M, Dianat I, Khatibi MS, Mansour SN, Fahiminia M, Hashemi A (2014) Review of environmental aspects and waste management of stone cutting and fabrication industries. J Master Cycles Waste Mang. 16:721–730

ABIROCHAS - Brazilian Association of the Ornamental Stone Industry. Available online: https://abirochas.com.br/wp-content/uploads/2022/03/Informe-01_2022-Exportacoes-2021.pdf

Ahmadi SF, Reisi M, Amiri MC.(2022) Reusing granite waste in eco-friendly foamed concrete as aggregate. J of Building Eng. 46. https://doi.org/10.1016/j.jobe.2021.103566

Guo Z, Tu A, Chen C, Lehman DE (2018) Mechanical properties, durability, and life-cycle assessment of concrete building blocks incorporating recycled concrete aggregates. J of Cleaner Production. 199(20):136–149

Instituto Aço Brasil – Available online. https://acobrasil.org.br/site/wp-content/uploads/2022/08/Estatistica-da-Siderurgia_2o_TRI_2022.pdf

Andrade LN, Amorim CC, Santos SV, Teixeira IF, Leão MMD, Lago RM (2015) Efficient demulsification of wastewater by steel furnace dust with amphiphilic and surface charge properties. Chemical Eng. J. 271:281–286

Vieira CMF, Andrade PM, Vernilli F, Monteiro SN (2006) Incorporation of fine steel sludge waste into red ceramic. Mat. Sci. and Eng. 427(2):142–147

Silva SF, Ribeiro CEG, Rodriguez RJS (2018) Physical and Mechanical Characterization of Artificial Stone with Marble Calcite Waste and Epoxy Resin. Mater Reser. 21(1)

Agrizzi CP, Carvalho EAS, Gadioli MCB, Barreto CNS, Azevedo ARG, Monteiro SN, Vieira CMF (2022) Comparison between synthetic and biodegradable Polymer matrices on the development of quartzite waste-based artificial stone. Sustainability.14(11)

Hamoush, S, Abu-Lebdeh T, Picornell M, Amer S (2011) Development of sustainable engineered stone cladding for toughness, durability, and energy conservation. Constr Build Mater 25:4006–4016

Gomes, MLPM, Carvalho EAS, Sobrinho LN, Monteiro SN, Rodriguez RJS, Vieira CMF (2019) Physical and mechanical properties of artificial stone produced with granite waste and vegetable polyurethane. In: Ikhmayies S, Li J, Vieira C, Margem J, de Oliveira Braga, F (eds) Green materials engineering. The minerals, metals & materials series. Springer, Cham. https://doi.org/10.1007/978-3-030-10383-5_3

Sarami N, Mahdavian L (2015) Effect of inorganic compound on artificial stones’ properties. Int J Ind Chem. 6:213–219. https://doi.org/10.1007/s40090-015-0045-9

Borselino C, Calbrese L, di Bella G (2009) Effects of powder concentration and type of resin on the performance of marble composite structures. Constr Build Mater 23:1915–1921. https://doi.org/10.1016/j.conbuildmat.2008.09.005

Demartini TJC, Rodriguez RJS, Silva FS (2018) Physical and mechanical evaluation of artificial marble produced with dolomitic marble residue processed by diamond–plated bladed gang-saws. J Market Res 7:308–313. https://doi.org/10.1016/j.jmrt.2018.02.001

Yu ZY, Gu Ruonan, S **gang, Cheng S, Chu J (2022) Polymeric solid wastes for efficient and stable solar desalination and the outdoor clean water production performance prediction. Separation and Purification Technology. https://doi.org/10.1016/j.seppur.2022.121938

Gomes, MLPMG, Carvalho EAS, Barreto GNS, Rodriguez RJS, Monteiro SN, Vieira CMF (2022) Development of sustainable artificial stone using granite waste and biodegradable polyurethane from castor oil. Sustainability. 14(11) https://www.mdpi.com/journal/sustainability

Clarinval A-M, Halleux J (2005) Classification of biodegradable polymers. Biodegradable Polym Industr Appl 3–31. https://doi.org/10.1533/9781845690762.1.3

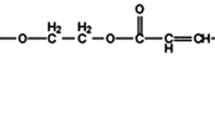

Rajalakshmi P, Marie JM, & Maria Xavier, A. J (2019) Castor oil-derived monomer ricinoleic acid based biodegradable unsaturated polyesters. Polymer Degradation and Stability 170. https://doi.org/10.1016/j.polymdegradstab.2019.109016

Brazilian Association of Technical Norms – ABNT. ABNT NBR 7181: soil – grain size analysis. Rio de Janeiro: ABNT; 2016 (In Portuguese).

Brazilian Association of Technical Norms – ABNT NBR MB 3388 (1991) Soil - Determination of the minimum void index of non-cohesive soils. Rio de Janeiro. (In Portuguese)

Brazilian Association of Technical Norms - ABNT NBR 15845–2 (2015). Rocks for cladding – Part 2: Determination of bulk density, apparent porosity and water absorption. Rio de Janeiro: ABNT. (In Portuguese)

Spanish Association of Standards and Certification - UNE-EN 14617–2 (2016) Test methods - Part 2: Determination of the flexural strength. Madrid: UNE-EN. (In Spanish)

Brazilian Association of Technical Norms - ABNT NBR 15.845–6:2015 – Rocks for classing- Part 6: Determination of modulus of rupture (three point bending). Rio de Janeiro: ABNT. (In Portuguese)

Lee DJ, Shin IJ (2002) Effects of vacuum, mold temperature and cooling rate on mechanical properties of press consolidated glass fiber/PET composites. Compos. Part A. 33:1107–1114.

Chiodi FC, Rodriguez EP (2020) Aplication guide for stone in coating (in Portuguese). São Paulo, Brazil: Abirochas. (In Portuguese).

Debnath S, Ranade R, Wunder SL, Mccool J, Boberick K, Baran G. (2004) Interface effects on mechanical properties of particle-reinforced composites. Dent Mater 20:677–86

Acknowledgements

The authors thank FAPERJ (process grant number E-26/200.139/20220) for funding the research, UENF for their support, and the companies ArcelorMittal and Brumagran for providing the wastes.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Gomes, M.L.P.M., de Carvalho Lírio, J.L.D., Carvalho, E.A.S., Barreto, G.N.S., Monteiro, S.N., Vieira, C.M.F. (2023). Production of Sustainable Artificial Stone from Granite Waste and Steel Waste and Polyurethane from Castor Oil. In: Zhang, M., et al. Characterization of Minerals, Metals, and Materials 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22576-5_53

Download citation

DOI: https://doi.org/10.1007/978-3-031-22576-5_53

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22575-8

Online ISBN: 978-3-031-22576-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)