Abstract

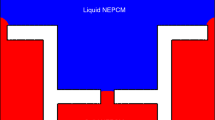

The dissolution of alumina in cryolite is a complex process, and better understanding is needed to ensure stable cell conditions and high energy efficiency. Additions of cold powder result in freezing of bath that hinders dissolution, and creation of rafts. The current work aims to develop and demonstrate a CFD framework in OpenFOAM for freezing of bath on a fed dose of alumina, based on the volume of fluid (VOF) method, where appropriate source- and sink terms are applied. Essential features have been verified by comparison with a Stefan problem, while simulating the dose as a floating rigid object demonstrate that a larger layer of freeze increase the dam** of its movement. When simulating the dose as an immiscible fluid, spreading will hinder enough freeze to be formed around the dose. Hence, the added source terms behave as intended, but improvements on the alumina-bath interactions are needed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Lavoie, P., Taylor, M.P., Metson, J.B.: A Review of Alumina Feeding and Dissolution Factors in Aluminum Reduction Cells. Metall Mater Trans B 47(4), 2690–2696 (2016). https://doi.org/10.1007/s11663-016-0680-3.

Gylver, S.E., Omdahl, N.H., Rørvik, S., Hansen, I., Nautnes, A., Neverdal, S.N., Einarsrud, K.E.: The Micro- and Macrostructure of Alumina Rafts. In: Chesonis, C. (ed.) Light Metals 2019. The Minerals, Metals & Materials Series, pp. 689–696. Springer, Cham (2019).

Kovacs, A.: “Modelling the feeding process for aluminium production”. PhD Thesis, University of Oxford, Oxford (2021).

Solheim, A., Skybakmoen, E.: Mass- and Heat Transfer During Dissolution of Alumina. In: Tomsett, A. (ed.) Light Metals 2020. The Minerals, Metals & Materials Series, pp. 664–671. Springer, Cham (2020).

Bardet, B., Foetisch, T., Renaudier, S., Rappaz, J., Flueck, M., Picasso, M.: Alumina Dissolution Modeling in Aluminium Electrolysis Cell Considering MHD Driven Convection and Thermal Impact. In: Williams, E. (ed.) Light Metals 2016, pp. 315–319 (2016).

Walker, D.: Alumina in aluminum smelting and its behaviour after addition to cryolite-based electrolytes, Phd thesis, University of Toronto, Toronto, 1993.

Dassylva-Raymond, V., Kiss, L.I., Poncsak, S., Chartrand, P., Bilodeau, J.-F., Guérard, S.: Modeling the behavior of alumina agglomerate in the Hall-Héroult process. In: Grandfield, J. (ed.) Light Metals 2014, pp. 603–608. Wiley, Hoboken, (2014).

Roger, T., Kiss, L., Dion, L., Guérard, S., Bilodeau, J.F., Bonneau, G., Santerre, R., Fraser, K.: Modeling of the Heat Exchange, the Phase Change, and Dissolution of Alumina Injected in Electrolysis Cells. In: Eskin, D. (ed.) Light Metals 2022. The Minerals, Metals & Materials Series, pp. 363–370. Springer, Cham (2022).

Voller, V.R., Prakash, C.: A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. International Journal of Heat and Mass Transfer 30(8), 1709–1719 (1987). https://doi.org/10.1016/0017-9310(87)90317-6.

Swaminathan, C.R., Voller, V.R.: A general enthalpy method for modeling solidification processes. MTB 23(5), 651–664 (1992). https://doi.org/10.1007/BF02649725.

Voller, V.R., Cross, M., Markatos, N.C.: An enthalpy method for convection/diffusion phase change. International Journal for Numerical Methods in Engineering 24(1), 271–284 (1987). https://doi.org/10.1002/nme.1620240119.

Torabi Rad, M.: solidificationMeltingSource: A Built-in fvOption in OpenFOAM®for Simulating Isothermal Solidification. In: Nóbrega, J.M., Jasak, H. (eds.) OpenFOAM®: Selected Papers of the 11th Workshop, pp. 455–464. Springer, Cham (2019). https://doi.org/10.1007/978-3-319-60846-4_32.

Muhammad, M.D., Badr, O., Yeung, H.: Validation of a CFD Melting and Solidification Model for Phase Change in Vertical Cylinders. Numerical Heat Transfer, Part A: Applications 68(5), 501–511. Taylor & Francis, (2015). https://doi.org/10.1080/10407782.2014.994432.

OpenCFD: OpenFOAM®- Official home of The Open Source Computational Fluid Dynamics (CFD) Toolbox. http://www.openfoam.com Accessed 2019-05-06.

Bird, R.B.: Transport Phenomena, 2nd ed. edn. Wiley, New York (2002).

Hirt, C.W., Nichols, B.D.: Volume of fluid (VOF) method for the dynamics of free boundaries. Journal of Computational Physics 39(1), 201–225 (1981).

Grjotheim, K., Kvande, H. (eds.): Introduction to Aluminium Electrolysis-Understanding the Hall-Heroult Process. Aluminium-Verlag, Düsseldorf (1993).

Greenshields, C., Weller, H.: Notes on Computational Fluid Dynamics: General Principles. CFD Direct Ltd, Reading, UK (2022). https://doc.cfd.direct/notes/cfd-general-principles/.

Alexiades, V., Solomon, A.D.: Mathematical Modeling of Melting and Freezing Processes, 1st edn. CRC Press, Washington, DC (1993).

Poncsák, S., Rakotondramanana, L., Kiss, L.I., Roger, T., Guérard, S., Bilodeau, J.-F.: Evolution of Mechanical Resistance of Alumina Raft Exposed to the Bath in Hall-Héroult Cells. In: Chesonis, C. (ed.) Light Metals 2019. The Minerals, Metals & Materials Series, pp. 667–673. Springer, Cham (2019).

Acknowledgements

The current work has been funded by SFI Metal Production (Centre for Research-based Innovation, 237738). The authors gratefully acknowledge the financial support from the Research Council of Norway and partners of the center.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Gylver, S.E., Einarsrud, K.E. (2023). CFD Modelling of Solidification and Melting of Bath During Raft Formation. In: Broek, S. (eds) Light Metals 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22532-1_92

Download citation

DOI: https://doi.org/10.1007/978-3-031-22532-1_92

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22531-4

Online ISBN: 978-3-031-22532-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)