Abstract

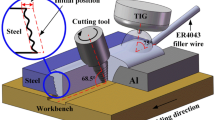

The overlap joints of aluminum alloy 5754 and galvanized advanced high strength steel (AHSS) are prepared by the laser welding-brazing technique. The microstructure in each characteristic zones of aluminum alloy 5754-AHSS dissimilar welded joint is observed. The α-Al is the main microstructure in the weld metal (WM), and Al–Si eutectics distributed in the grain boundary are also found. The microstructure of AHSS base metal (BM) is determined as martensite and ferrite. The tensile test results show that the aluminum alloy 5754-AHSS dissimilar welded joint fractured in the aluminum alloy BM with tensile strength of 238.4 MPa. The suitable thickness of the intermetallic compound (IMC) layer makes the BMs effectively bonded and difficult to initiate cracks. Thus, the formation of the continuous IMC layer is regarded as the main factor to improve the mechanical properties of the overlap joint.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Goede M, Stehlin M, Rafflenbeul L, Kopp G, Beeh E (2008) Super light car-Lightweight construction thanks to a multi-material design and function integration. Eur Transp Res Rev 1(1):5–10

Yang J, Oliveira JP, Li YL, Tan CW, Gao CK, Zhao YX, Yu ZS (2022) Laser techniques for dissimilar joining of aluminum alloys to steels: a critical review. J Mater Process Technol 301:117443

Miller WS, Zhuang L, Bottema J, Wittebrood AJ, Smet PD, Haszler A, Vieregge A (2000) Recent development in aluminium alloys for the automotive industry. Mater Sci Eng A 280(1):37–49

Qiu RF, Satonaka S, Iwamoto C (2009) Effect of interfacial reaction layer continuity on the tensile strength of resistance spot welded joints between aluminum alloy and steels. Mater Des 30(9):3686–3689

Yang J, Li YL, Zhang H, Guo W, Weckman D, Zhou N (2015) Dissimilar laser welding/brazing of 5754 aluminum alloy to DP980 steel: mechanical properties and interfacial microstructure. Metall Mater Trans A 46(11):5149–5157

Yang J, Hu AM, Li YL, Zhang PL, Chandra Saha D, Yu ZS (2019) Heat input, intermetallic compounds and mechanical properties of Al/steel cold metal transfer joints. J Mater Process Tech 272:40–46

Xue JY, Li YX, Chen H, Zhu ZT (2018) Wettability, microstructure and properties of 6061 aluminum alloy/304 stainless steel butt joint achieved by laser-metal inert-gas hybrid welding-brazing. T Nonferr Metal Soc 28(10):1938–1946

Sun YF, Fujii H, Takaki N, Okitsu Y (2013) Microstructure and mechanical properties of dissimilar Al alloy/steel joints prepared by a flat spot friction stir welding technique. Mater Des 47:350–357

Dang HQ, Yu HP (2022) Improving the quality of Al-Fe tube joints manufactured via magnetic pulse welding using an inclined-wall field shaper. J Manuf Process 73:78–89

Yang BY, Lin DY, **a HB, Li HY, Wang PH, Jiao JK, Chen X, Tan CW, Li LQ, Wang Q, Ma NS (2022) Welding characterization evolutions for dual spot laser welded-brazed Al/steel joint with various spot configurations. J Mater Res Technol 19:697–708

Torkamany MJ, Tahamtan S, Sabbaghzadeh J (2010) Dissimilar welding of carbon steel to 5754 aluminum alloy by Nd:YAG pulsed laser. Mater Des 31(1):458–465

Lee KJ, Kumai S, Arai T, Aizawa T (2007) Interfacial microstructure and strength of steel/aluminum alloy lap joint fabricated by magnetic pressure seam welding. Mater Sci Eng A 471(1–2):95–101

Wang JT, Fu X, Zhang LB, Zhang Z, Liu JH, Chen S (2021) A short review on laser welding/brazing of aluminum alloy to steel. Int J Adv Manuf Tech 112(9–10):2399–2411

Watanabe M, Feng KY, Nakamura Y, Kumai S (2011) Growth manner of intermetallic compound layer produced at welding interface of friction stir spot welded aluminum/steel lap joint. Mater Trans 52(5):953–959

Dharmendra C, Rao KP, Wilden J, Reich S (2011) Study on laser welding–brazing of zinc coated steel to aluminum alloy with a zinc based filler. Mater Sci Eng A 528(3):1497–1503

Yang J, Su JH, Gao CK, Zhao YX, Liu HB, Oliveira JP, Tan CW, Yu ZS (2021) Effect of heat input on interfacial microstructure, tensile and bending properties of dissimilar Al/steel lap joints by laser welding-brazing. Opt Laser Technol 142:107218

Hu YY, Zhang YM, Mi GY, Wang CM, Zhang W, Zhang X (2021) Effects of Si contents in filling wires on microstructure evolution and properties of Al-steel dissimilar joint by laser welding-brazing. J Mater Res Technol 15:1896–1904

Zhu CX, Tang XH, He Y, Lu FG, Cui HC (2018) Effect of preheating on the defects and microstructure in NG-GMA welding of 5083 Al-alloy. J Mater Process Tech 251:214–224

Yuan XY, Lu HF, Chen KX, Ning XS (2011) Effect of burning rate on solidification microstructure of thermite welds. Rare Metal Mat Eng 40(S1):440–442

Cheng JW, Song G, Zhang ZD, Khan MS, Liu ZF, Liu LM (2022) Improving heat-affected zone softening of aluminum alloys by in-situ cooling and post-weld rolling. J Mater Process Tech 306:117639

Wu SC, Yu X, Zuo RZ (2013) Porosity, element loss and strength model on softening behavior of hybrid laser arc welded Al–Zn–Mg–Cu alloy with synchrotron radiation analysis. Weld J 92(3):64–71

Wang L, Unocic KA, Tortorelli PF, Santella M, Chen X (2021) Precipitation behavior near shrinkage porosity in a large sand casting of Haynes 282 alloy. Materialia 15:101035

Cao XL, Xu PQ, Cao ZY, Gou N, Yu BB (2015) Research on microstructure and element diffusion in YG20/45# steel laser welds. Chin J Lasers 42(3):0303006

Qin GL, Ao ZY, Chen Y, Zhang CS, Geng PH (2019) Formability behavior of Al/steel MIG arc brazed-fusion welded joint. J Mater Process Tech 273:116255

Cao XB, Duan JA, Li Z, Chang BQ, Xu C, **e Z (2022) An investigation on laser/DP-MIG hybrid weldability of aluminum to Al–Si coated boron steel. Opt Laser Technol 150:107939

Dong HG, Hu WJ, Duan YP, Wang XD, Dong C (2012) Dissimilar metal joining of aluminum alloy to galvanized steel with Al–Si, Al–Cu, Al–Si–Cu and Zn–Al filler wires. J Mater Process Tech 212(2):458–464

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant no. 52071193).

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Hu, T., Li, Z., Dong, W., Ding, K., Gao, Y. (2023). Study on the Microstructure and Mechanical Properties of Aluminum Alloy 5754 to Advanced High Strength Steel by the Laser Welding-Brazing Technique. In: TMS 2023 152nd Annual Meeting & Exhibition Supplemental Proceedings. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22524-6_41

Download citation

DOI: https://doi.org/10.1007/978-3-031-22524-6_41

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22523-9

Online ISBN: 978-3-031-22524-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)