Abstract

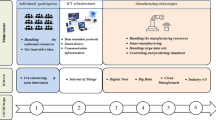

With recent advances in the information revolution, Digital Twin, with its complementary technologies, especially Big Data, Internet of Thing (IoT), Artificial Intelligence (AI) and Multi-Agent Systems (MAS), is becoming the core of novel strategies to maintain sustainability in Industry 4.0 networks and smart manufacturing. Despite the potential advantages of Digital Twin, such as virtual accessibility, remote monitoring, and timely customisation, not all sorts of enterprises have the resources or capabilities to incorporate such an advanced system, particularly Small to Medium size Enterprises (SMEs), due to their volatile nature of Supply Chains (SC). In this context, a Cyber-Physical Systems (CPS)-based, Agent Oriented Smart Factory (xAOSF) framework presents an over-arching SC architecture, with an associated Agent Oriented Storage and Retrieval (AOSR) based warehouse management strategy to help bridge the gap between Industry 4.0 frameworks and SME-oriented setups. This paper presents an approach towards realising the concept of Digital Twin via the xAOSF/AOSR framework, utilising state-of-the-art semantic modelling and analytical industrial tools. An amalgamation of CPS and Big Data Analytics is important to establish an effective Digital Twin to improve system scalability, security, and efficiency. This paper brings attention to this critical intersection and highlights how the xAOSF/AOSR framework can be scaled to implement Digital Twin effectively, which helps in analysing the bottleneck and threshold-states in real-time, especially in manufacturing organisations, which can lead towards full autonomy in an Industry 4.0 environment.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Al-Rejal, H.M.A., Doleh, J.D.A., Salhieh, L.M., Udin, Z.M., Mohtar, S.: Barriers of supply chain management practices in manufacturing companies in Republic of Yemen: pre-war perspective. Int. J. Supply Chain Manag. 6(3), 246–251 (2017)

Andulkar, M., Le, D.T., Berger, U.: A multi-case study on Industry 4.0 for SMEs in Brandenburg Germany. In: Proceedings of the 51st Hawaii International Conference on System Sciences, pp. 4544 –4553 (2018). http://hdl.handle.net/10125/50463

Bogdan, P.: A cyber-physical systems approach to personalized medicine: challenges and opportunities for noc-based multicore platforms. In: 2015 Design, Automation & Test in Europe Conference & Exhibition (DATE), pp. 253–258. IEEE (2015)

Business2Community. Issues in Warehouse Management Systems (2018). https://www.business2community.com/product-management/top-5-warehouse-management-problems-solve-02027463. Accessed 17 July 2018

Centobelli, P., Converso, G., Murino, T., Santillo, L.: Flow shop scheduling algorithm to optimize warehouse activities. Int. J. Indust. Eng. Comput. 7(1), 49–66 (2016)

Demo3D-Simulation-Tool. Demo3D, A Product of SOLIDWORKS and Rockwell Automation Industry, USA, for Simulating Industrial Setups (2019). https://www.demo3d.com/home/. Accessed 31 May 2019

Freeman, C., Louçã, F.: As Time Goes By: From the Industrial Revolutions to the Information Revolution. Oxford University Press (2001)

Gagliardi, J.P., Renaud, J., Ruiz, A.: Models for automated storage and retrieval systems: a literature review. Int. J. Prod. Res. 50(24), 7110–7125 (2012)

Gartner. Gartner Survey - Digital Twin in Manufacturing,. https://www.gartner.com/en/newsroom/press-releases/2019-02-20-gartner-survey-reveals-digital-twins-are-entering-mai. Accessed 20 July 2021

Llonch, M., Bernardo, M., Presas, P.: A case study of a simultaneous integration in an SME: implementation process and cost analysis. Int. J. Qual. Reliab. Manag. 35(2), 319–334 (2018)

Lu, W., Giannikas, V., McFarlane, D., Hyde, J.: The Role of Distributed Intelligence in Warehouse Management Systems, pp. 63–77 (2014)

Ma, H., Shufei, S., Simon, D., Fei, M.: Ensemble multi-objective biogeography-based optimization with application to automated warehouse scheduling. Eng. Appl. Artif. Intell. 44, 79–90 (2015)

Maggio, M., et al.: Comparison of decision-making strategies for self-optimization in autonomic computing systems. ACM Trans. Autonom. Adapt. Syst. 7(4), 1–32 (2012)

Manzini, R., Accorsi, R., Baruffaldi, G., Cennerazzo, T., Gamberi, M.: Travel time models for deep-lane unit-load autonomous vehicle storage and retrieval system (AVS/RS). Int. J. Prod. Res. 54(14), 4286–4304 (2016)

Company McKinsey. The Impact and Future of Manufacturing (2019). https://www.mckinsey.com/business-functions/operations/our-insights/the-future-of-manufacturing. Accessed 3 Apr 2019

Müller, J.M., Buliga, O., Voigt, K.-I.: Fortune favors the prepared: how SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Change 132(C), 2–17 (2018)

Poon, T.C., Choy, K.L., Chow, H.K.H., Lau, H.C.W., Chan, F.T.S., Ho, K.C.: A RFID case-based logistics resource management system for managing order-picking operations in warehouses. Exp. Syst. Appl. 36(4), 8277–8301 (2009)

Qi, Q., Tao, F.: Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access 6, 3585–3593 (2018)

Richards, G.: Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse. Kogan Page Publishers (2017)

Masdefiol, M.d.M.R., Stävmo, F.: Industry 4.0–only designed to fit the german automotive industry: a multiple case study on the feasibility of industry 4.0 to Swedish SMES (2016)

Shao, G., Helu, M.: Framework for a digital twin in manufacturing: scope and requirements. Manuf. Lett. 24, 105–107 (2020)

Sommer, L.: Industrial revolution Industry 4.0: are German manufacturing SMEs the first victims of this revolution? J. Indust. Eng. Manag. 8(5), 1512 (2015)

Din, F.U., Anwer, S.: ERP success and logistical performance indicators a critical view. Int. J. Comput. Sci. Issue. 223–229 (2013). http://www.ijcsi.org/papers/IJCSI-10-6-1-223-229.pdf

Ud Din, F., Henskens, F., Paul, D., Wallis, M.: Agent-oriented smart factory (AOSF): an MAS based framework for SMEs under Industry 4.0. In: Jezic, G., Chen-Burger, Y.-H.J., Howlett, R.J., Jain, L.C., Vlacic, L., Šperka, R. (eds.) KES-AMSTA-18 2018. SIST, vol. 96, pp. 44–54. Springer, Cham (2019). https://doi.org/10.1007/978-3-319-92031-3_5

Ud Din, F., Henskens, F., Paul, D., Wallis, M.: Formalisation of problem and domain definition for agent oriented smart factory (AOSF). In: 2018 IEEE Region Ten Symposium (Tensymp), pp. 265–270. IEEE (2019)

Ud Din, F., Henskens, F., Paul, D., Wallis, M., Hashmi, M.A.: AOSR: an agent oriented storage and retrieval WMS planner for SMEs, associated with AOSF framework, under Industry 4.0. Int. J. Appl. Decis. Sci. Accepted (2021)

Ud Din, F., Paul, D., Henskens, F., Wallis, M.: Conceptualised visualisation of extended agent oriented smart factory (XAOSF) framework with associated AOSR-WMS system. J. Softw. (2021)

Din, F.U., Paul, D., Ryan, J., Henskens, F., Wallis, M.: Revitalising and validating the novel approach of xAOSF framework under Industry 4.0 in comparison with linear SC. In: Jezic, G., Chen-Burger, J., Kusek, M., Sperka, R., Howlett, R.J., Jain, L.C. (eds.) Agents and Multi-Agent Systems: Technologies and Applications 2020. SIST, vol. 186, pp. 3–16. Springer, Singapore (2020). https://doi.org/10.1007/978-981-15-5764-4_1

Ud Din, F., Paul, D., Ryan, J., Henskens, F., Wallis, M.: Validating time efficiency of AOSR 2.0: a novel WMS planner algorithm for SMEs, under Industry 4.0. J. Softw. (2020)

Ud Din, F., Paul, D., Ryan, J., Henskens, F., Wallis, M.: Aosr 2.0: a novel approach and thorough validation of an agent-oriented storage and retrieval WMS planner for SMES, under industry 4.0. Future Internet 13(6), 155 (2021)

Winkelhaus, S., Grosse, E.H.: Logistics 4.0: a systematic review towards a new logistics system. Int. J. Prod. Res. 58(1), 18–43 (2020)

Da Xu, L., Duan, L.: Big data for cyber physical systems in industry 4.0: a survey. Enterp. Inf. Syst. 13(2), 148–169 (2019)

Xu, L.D., Xu, E.L., Li, L.: Industry 4.0: state of the art and future trends. Int. J. Prod. Res. 56(8), 2941–2962 (2018). https://doi.org/10.1080/00207543.2018.1444806

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Ud Din, F., Paul, D. (2023). Demystifying xAOSF/AOSR Framework in the Context of Digital Twin and Industry 4.0. In: Arai, K. (eds) Intelligent Systems and Applications. IntelliSys 2022. Lecture Notes in Networks and Systems, vol 544. Springer, Cham. https://doi.org/10.1007/978-3-031-16075-2_44

Download citation

DOI: https://doi.org/10.1007/978-3-031-16075-2_44

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-16074-5

Online ISBN: 978-3-031-16075-2

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)