Abstract

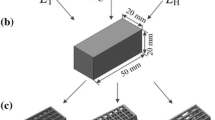

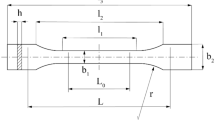

The advantages of AM (Additive Manufacturing) to manufacture complex geometries and custom flexible structures (shape, density, geometry etc.) provides the possibility to use the elastic properties of different materials in order to obtain elastic profiles that could be adapted to a specific customized application. Recent studies established that manufacturing and geometrical parameters like unit cell size and topology, have a defined influence on the stiffness of complex structures like lattice structures, all due to the variation in the volume of material used. This highlights the possibility of designing elastic behavior of structures that could be implemented, for example, in rehabilitation programs which usually use elastic products with highly specific levels of resistance. Therefore, the objective of this works focuses on evaluating the use of the statistical treatment of the data as a guide to predict the behavior of the structures for the design of customized rehabilitation products. A case study based on the use of contour plots as a prediction tool have been carried out. Several TPU lattice specimens were modelled and tested by a simulation of a compression process using finite element analysis (FEA) tools. The reaction force against compression process of several lattice specimens were obtained, showing that the values were within the range of values predicted by the contour plot, validating the prediction. In the same way, the prediction capability with non-studied parameter values, and using a lower number of parameters at the same time were analysed, getting favourable results.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Jiménez, M., et al.: Additive Manufacturing Technologies : An Overview about 3D Printing Methods and Future Prospects. Complexity (2019)

Abdulhameed, O., Al-Ahmari, A., Ameen, W., Mian, S.: Additive manufacturing: challenges, trends, and applications. Adv. Mech. Eng. 11(2), 168781401882288 (2019)

Dhinakaran, V., Kumar, K., Ram, P., Ravichandran, M., Vinayagamoorthy, M.: A review on recent advancements in fused deposition modeling. Materials Today: Proceedings 27, 752–756 (2020)

León, M., Marcos-Fernández, Á., León, A.: Impresión 3D Con Materiales Elástoméricos. Revista De Plásticos Modernos 118(747) (2019)

González-Henríquez, C., Sarabia-Vallejos, M., Rodriguez-Hernandez, J.: Polymers for additive manufacturing and 4D-printing: materials, methodologies, and biomedical applications. Prog. Polym. Sci. 94, 57–116 (2019)

Pazhamannil, R., Govindan, P.: Current State and Future Scope of Additive Manufacturing Technologies via Vat Photopolymerization. Materials Today: Proceedings (2021)

**ao, J., Gao, Y.: The manufacture of 3D printing of medical grade TPU. Progress in Additive Manufacturing 2(3), 117–123 (2017)

Haryńska, A., Gubanska, I., Kucinska-Lipka, J., Janik, H.: Fabrication and characterization of flexible medical-grade TPU filament for fused deposition modeling 3DP technology. Polymers 10(12), 1304 (2018)

Harris, C., Jursik, N., Rochefort, W., Walker, T.: Additive manufacturing with Soft TPU – adhesion strength in multimaterial flexible joints. Frontiers in Mechanical Eng. 5,1–6 (2019)

León, M., Marcos-Fernández, Á.: Impresión 3D Con Materiales Elástoméricos. Revista De Plásticos Modernos 118(747) (2019)

The Evolution of the 3D Printing Materials Market in 2019: Polymers - FacFox Docs https://facfox.com/docs/kb/the-evolution-of-the-3d-printing-materials-market-in-2019-polymers Accessed 25 Mar 2022

The Evolution of 3D Printing Materials Market: Trends and Opportunities in 2019 - AMFG https://amfg.ai/2019/11/21/the-evolution-of-3d-printing-materials-market-trends-and-opportunities-in-2019/ Accessed 25 Mar 2022

Rodríguez-Parada, L., de la Rosa, S., Mayuet, P.: Influence of 3D-printed TPU properties for the design of elastic products. Polymers, 13(15), 2519 (2021)

Zhu, J., Zhou, H., Wang, C., Zhou, L., Yuan, S., Zhang, W.: A review of topology optimization for additive manufacturing: status and challenges. Chin. J. Aeronaut. 34(1), 91–110 (2021)

Panetta, J., et al.: Elastic textures for additive fabrication. ACM Trans. Graphics 34(4), 1–12 (2015)

Pham, M., Liu, C., Todd, I., Lertthanasarn, J.: Damage-tolerant architected materials inspired by crystal microstructure. Nature 565(7739), 305–311 (2019)

Momeni, K., Mofidian, S., Bardaweel, H.: Systematic design of high-strength multicomponent metamaterials. Mater. Des. 183, 108124 (2019)

Niknam, H., Akbarzadeh, A.: Graded lattice structures: simultaneous enhancement in stiffness and energy absorption. Mater. Des. 196, 109129 (2020)

Davami, K., Mohsenizadeh, M., Munther, M., Palma, T., Beheshti, A., Momeni, K.: Dynamic Energy Absorption Characteristics of Additivelymanufactured Shape-Recovering Lattice Structures. Materials Research Express 6(4), 045302 (2019)

Rahman, O., Koohbor, B.: Optimization of energy absorption performance of polymer honeycombs by density gradation. Composites Part C: Open Access 3, 100052 (2020)

Habib, F., Iovenitti, P., Masood, S., Nikzad, M., Ruan, D.: Design and evaluation of 3D printed polymeric cellular materials for dynamic energy absorption. Int. J. Adv. Manuf. Technol. 103(5–8), 2347–2361 (2019)

Estructuras Aligeradas De Tipo Lattice En Fabricación Aditiva | Blog Ingenius https://eddm.es/blog-ingenius/estructuras-aligeradas-tipo-lattice-fabricacion-aditiva/ Accessed 25 Mar 2022

Bates, S., Farrow, I., Trask, R.: 3D printed polyurethane honeycombs for repeated tailored energy absorption. Mater. Des. 112, 172–183 (2016)

Bhuvanesh-Kumar, M., Sathiya, P.: Methods and materials for additive manufacturing: a critical review on advancements and challenges. Thin-Walled Structures 159, 107228 (2020)

Shen, F., et al.: Energy absorption of thermoplastic polyurethane lattice structures via 3D printing: modeling and prediction. Int. J. Appl. Mech. 8(7), 1–13 (2016)

Bates, S., Farrow, I., Trask, R.: Compressive behaviour of 3D printed thermoplastic polyurethane honeycombs with graded densities. Mater. Des. 162, 130–142 (2019)

Maskery, I., et al.: An investigation into reinforced and functionally graded lattice structures. J. Cell. Plast. 53(2), 151–165 (2017)

Bates , S., Farrow , I., Trask , R.: 3D printed elastic honeycombs with graded density for tailorable energy absorption. In: Park, G. ( Ed.): Active and Passive Smart Structures and Integrated Systems 2016 : Las Vegas , Neva. 9799 (2016)

Schumacher, C., Bickel, B., Rys, J., Marschner, S., Daraio, C., Gross, M.: Microstructures to control elasticity in 3D printing. ACM Trans. Graphics 34(4), 1–13 (2015)

World Health Organization - Rehabilitation.World Health Organization - Rehabilitation https://www.who.int/es/news-room/fact-sheets/detail/rehabilitation Accessed 25 Mar 2022

Lunsford, C., Grindle, G., Salatin, B., Dicianno, B.: Innovations with 3-dimensional printing in physical medicine and rehabilitation: a review of the literature. PM and R 8(12), 1201-1212 (2016)

de la Rosa, S., Mayuet, P., Rodríguez-Parada, L.: An overview of the additive manufacturing capabilities in the development of rehabilitation products with customized elastic properties. IOP Conference Series: Materials Sci. Eng. 1193(1), 12122 (2021)

De La Rosa, S., Mayuet, P.F., Ramón, J., Salgueiro, M., Rodríguez-Parada, L.: Design of customized TPU lattice structures for additive manufacturing: influence on the functional properties in elastic products. Polymers 13(24), 4341 (2021)

Escalona, A., Naranjo, O., Lagos, S., Solís, F.: Parámetros de Normalidad en Fuerzas de Prensión de Mano en Sujetos de Ambos Sexos de 7 a 17 Años de Edad. Revista chilena de pediatría 80(5) (2009)

Material TPU 95A Ultimaker: Filament For 3D Printing Durable And Flexible Components https://ultimaker.com/es/materials/tpu-95a Accessed 25 Mar 2022

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

de la Rosa, S., Mayuet, P.F., Pardo-Vicente, MA., Rodríguez-Parada, L. (2023). Influence of TPU Lattice Structures on Functional Properties for the Design of Customized Rehabilitation Products. In: Gerbino, S., Lanzotti, A., Martorelli, M., Mirálbes Buil, R., Rizzi, C., Roucoules, L. (eds) Advances on Mechanics, Design Engineering and Manufacturing IV. JCM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-15928-2_80

Download citation

DOI: https://doi.org/10.1007/978-3-031-15928-2_80

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-15927-5

Online ISBN: 978-3-031-15928-2

eBook Packages: EngineeringEngineering (R0)