Abstract

Sheet metal forming is widely used in many industries, especially in manufacturing automotive body parts and white goods. For many years, coated kitchen utensils are being used because of their properties such as non-stick property. The most used coating is polytetrafluoroethylene (PTFE), known as Teflon. Kitchen utensils are mainly manufactured by deep drawing processes, which require a good knowledge of the behaviour and the formability of the material. To characterize the formability of the sheets, it is necessary to determine the forming limit diagram (FLD). The FLD can be obtained throughout different essays such as Marciniack test and Nakazima test. With the FLD it is possible to compare the formability of different materials. Also, knowing the FLD can reduce the process’ development time. In this work, aluminium sheets coated with Teflon are studied experimentally. Firstly, dilatometer and tensile tests were carried out to investigate the thermal and the mechanical properties of the coated sheets. Furthermore, Nakazima test was conducted to obtain the forming limit diagram (FLD) of the studied material. Also, a numerical approach based on the Finite Element Method (FEM) is being developed to determine the limit of the considered deep drawing process.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Erdin, M.E., Ozdilli, O.: Deep drawing of polymer coated metal sheets. J. Mech. Sci. Technol.33, 5383–5392 (2019). https://doi.org/10.1007/s12206-019-1032-4

Lim, Y., An, T., Ko, S., Kim, N.: Formability of coated vinyl on sheet metal during deep drawing process. J. Mater. Process. Technol. https://doi.org/10.1016/j.jmatprotec.2015.08.016

Keeler, S.P.: Determination of Forming Limits in Automotive Stam**s. Society of Automotive Engineers (1965). https://doi.org/10.4271/650535

Goodwin, G. M.: Application of Strain Analysis to Sheet Metal Forming Problems in the Press Shop (No. 680093). SAE International Warrendale (1968). https://doi.org/10.4271/680093

Coëra, J., Laurenta, H., Oliveirab1, M.C., Manacha, P.-Y., Menezesb, L.F.: Detailed experimental and numerical analysis of a cylindrical cup deep drawing: pros and cons of using solid-shell elements. Int. J. Mater. Form. 11, 357–373 (2018)

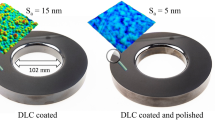

Flegler, F., Groche, P., Abraham, T., Bräuer, G.: Dry deep drawing of aluminum and the influence of sheet metal roughness. JOM 72(7), 2511–2516 (2020). https://doi.org/10.1007/s11837-020-04173-w

Mahesh, B.R., Satheesh, J.: Experimental and numerical analysis of forming limit diagram of Al-5052 using Nakazima test. In: AIP Conference Proceedings, vol. 2316, p. 030007 (2021). https://doi.org/10.1063/5.0036538

Kim, H.Y., Hwang, B.C., Bae, W.B.: An experimental study on forming characteristics of pre-coated sheet metal. J. Mater. Process. Technol. 120, 290–295 (2001)

Hadj Kacema, N., Haddar, N., Elleuch, R.: The failure analysis of an automotive shock absorber cup during manufacturing process, Mech. Ind. 17, 604–607 (2016)

Duan, X., Jain, M., Wilkinson, D.S.: Development of a heterogeneous microstructurally based finite element model for the prediction of forming limit diagram for sheet material. Metall. Mater. Trans. A 37, 3489 (2006)

Behrens, B.-A., Bouguecha, A., Vucetic, M., Grbic, N.: FEA of the clinching process of short fiber reinforced thermoplastic with an aluminum sheet using LS-DYNA. AIP Conf. Proc. 1769, 100012 (2016)

Behrens, B.-A., Bouguecha, A., Götze, T.: Numerical calculation of the deformation of aluminum sheets by means of synthetic melt pressure. Metall. 65 (1–2), 29–31 (2016)

DIN EN ISO 12004-2: Metallic materials – Determination of forming-limit curves for sheet and strip – Part 2: determination of forming limit curves in the laboratory (2021)

DIN EN ISO 6892-1:2019, Metallic materials – Tensile testing – Part 1: Method of test at room temperature (ISO 6892-1 (2019)

Veenaas, S., Behrens, G., Kröger, K., Vollertsen, F.: Determination of forming limit diagrams for thin foil materials based on scaled Nakajima test. Appl. Mech. Mater. 794, 190–198 (2015). https://doi.org/10.4028/www.scientific.net/AMM.794.190

Nakajima, K., Kikuma, T., Hasuka, T.: Study on the formability of steel sheets. Yawata Technical Report 284, 141–154 (1968). https://doi.org/10.2355/isi**ternational1966.24.284

Kirby, R.K.: Thermal expansion of polytetrafluoroethylene (Teflon) from - 1900 to +3000 C. J. Res. Natl. Bureau Stand. 57(2) (1956), Research Paper 2696

Acknowledgement

This project is carried out under the mobidoc scheme 248 “Development of a ceramic non-stick coating, with extended formability limits on sheet metal for deep drawing applications”, funded by the EU through the EMORI program and managed by the ANPR.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Abdennadher, M., Bouguecha, A., Behrens, BA., Stockburger, E., Elleuch, R. (2023). Experimental Characterization of Coated Aluminum Sheets for Deep Drawing Applications. In: Walha, L., et al. Design and Modeling of Mechanical Systems - V. CMSM 2021. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-14615-2_94

Download citation

DOI: https://doi.org/10.1007/978-3-031-14615-2_94

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-14614-5

Online ISBN: 978-3-031-14615-2

eBook Packages: EngineeringEngineering (R0)