Abstract

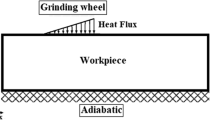

The paper presents a technique for numerical simulation of the thermal deformation behavior of the load-bearing system of a double-sided face grinder using the Ansys. The machine tool is considered in two modes of its operation: at idle and working strokes. Spindle bearings, heat fluxes from cutting fluid, heat fluxes from main engines are presented as the main heat sources. Basic data for convective and heat fluxes were taken according to the methods used in the calculations of machine tools. To obtain adequate models, the values of heat and convective fluxes were refined from experimental data for temperatures and temperature displacements. Convective heat transfer in the thermal model of the machine tool was set for 450 surfaces. Heat fluxes were specified for 161 surfaces. The simulation of the thermal behavior of the machine tool was carried out for 6 h of its operation in the Ansys. The ten-node Solid227 element was used as a typical finite element. The problem of thermoelasticity was solved in a coupled formulation. The error in calculating thermal characteristics did not exceed 0.5 ℃, the error in calculating temperature displacements did not exceed 5 µm. The results of computer simulation confirmed the experimental relationships characteristic of this group of machine tools in the positions of the left and right grinding wheel. At idle, the mutual position of the grinding wheels can be attributed to the type of deformation as “below is wider”. On the working stroke, this deformation state can be represented as “below is narrowly”.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ito, Y.: Thermal Deformation in Machine Tools. McGraw Hill Professional (2010)

Mayr, J., Jedrzejewski, J., Uhlmann, E., et al.: Thermal issues in machine tools. CIRP Ann. Manuf. Technol. 61, 771–791 (2012). https://doi.org/10.1016/j.cirp.2012.05.008

Kuznecov, A.P.: Teplovoe povedenie i tochnost’ metallorezhushchih stankov (Thermal behavior and accuracy of machine tools). MGTU “Stankin”, YAnus-K, Moscow (2011)

Bryan, J.: International status of thermal error research. CIRP Ann. Manuf. Technol. 39, 645–656 (1990). https://doi.org/10.1016/S0007-8506(07)63001-7

Kuznecov, A.P.: Teplovoj rezhim metallorezhushchih stankov (Thermal regime of metal-cutting machines). MGTU “Stankin”, YAnus-K, Moscow (2013)

Kuznecov, A.P.: Teplovye processy v metallorezhushchih stankah (Thermal processes in metal-cutting machines). Tekhnosfera, Moscow (2019)

Bushuev, V.V., Kuznetsov, A.P., Khomyakov, V.S., et al.: Precision and efficiency of metal-cutting machines. Russ. Engin. Res. 36, 762–773 (2016). https://doi.org/10.3103/S1068798X16090070

Bushuev, V.V., Kuznetsov, A.P., Sabirov, F.S., et al.: Trends in research on metal-cutting machines. Russ. Engin. Res. 36, 488–495 (2016). https://doi.org/10.3103/S1068798X16060083

Fu, G., Tao, C., **e, Y., Lu, C., Gao, H.: Temperature-sensitive point selection for thermal error modeling of machine tool spindle by considering heat source regions. Int. J. Adv. Manufact. Technol. 112(9–10), 2447–2460 (2021). https://doi.org/10.1007/s00170-020-06417-0

Fan, J., Wang, P., Tao, H., Pan, R.: A thermal deformation prediction method for grinding machine’ spindle. Int. J. Adv. Manufact. Technol. 118(3–4), 1125–1139 (2021). https://doi.org/10.1007/s00170-021-07931-5

Naumann, A., Ruprecht, D., Wensch, J.: Toward transient finite element simulation of thermal deformation of machine tools in real-time. Comput. Mech. 62(5), 929–942 (2018). https://doi.org/10.1007/s00466-018-1540-6

Ge, Z., Ding, X.: Thermal error control method based on thermal deformation balance principle for the precision parts of machine tools. Int. J. Adv. Manufactur. Technol. 97(1–4), 1253–1268 (2018). https://doi.org/10.1007/s00170-018-1992-z

Fang, B., Gu, T., Ye, D., Luo, T.: An improved thermo-mechanical model for vertical machining center. Int. J. Adv. Manufactur. Technol. 87(9–12), 2581–2592 (2016). https://doi.org/10.1007/s00170-016-8651-z

Polyakov, A.N., Goncharov, A.N.: Snizhenie temperaturnoj pogreshnosti stankov s CHPU na osnove upravleniya dvizheniem ih rabochih organov (Reducing the temperature error of CNC machine tools based on the control of the movement of their working bodies). Vuzovskoe obrazovanie, Saratov (2019)

Li, Y., Zhao, W., Lan, S., et al.: A review on spindle thermal error compensation in machine tools. Int. J. Mach. Tools Manuf 95, 20–38 (2015). https://doi.org/10.1016/j.ijmachtools.2015.04.008

Liu, S., Lin, M.: Thermal–mechanical coupling analysis and experimental study on CNC machine tool feed mechanism. Int. J. Precis. Eng. Manuf. 20(6), 993–1006 (2019). https://doi.org/10.1007/s12541-019-00069-1

Zhang, T., Ye, W., Liang, R., et al.: Temperature variable optimization for precision machine tool thermal error compensation on optimal threshold. Chin. J. Mech. Eng. 26, 158–165 (2013). https://doi.org/10.3901/CJME.2013.01.158

Cao, H., Zhu, L., Li, X., Chen, P., Chen, Y.: Thermal error compensation of dry hobbing machine tool considering workpiece thermal deformation. Int. J. Adv. Manufactur. Technol. 86(5–8), 1739–1751 (2016). https://doi.org/10.1007/s00170-015-8314-5

Li, T., Li, F., Jiang, Y., Wang, H.: Thermal error modeling and compensation of a heavy gantry-type machine tool and its verification in machining. Int. J. Adv. Manufactur. Technol. 92(9–12), 3073–3092 (2017). https://doi.org/10.1007/s00170-017-0353-7

Ramesh, R., Mannan, M.A., Poo, A.N.: Error compensation in machine tools—a review part II: thermal errors. Int. J. Mach. Tool Manuf. 40, 1257–1284 (2000). https://doi.org/10.1016/S0890-6955(00)00010-9

Yao, X.-D., Du, Z.-C., Ge, G.-Y., Yang, J.-G.: Dynamic temperature gradient and unfalsified control approach for machine tool thermal error compensation. J. Mech. Sci. Technol. 34(1), 319–331 (2020). https://doi.org/10.1007/s12206-019-1232-y

Huang, Z., Liu, Y., Du, L., Yang, H.: Thermal error analysis, modeling and compensation of five-axis machine tools. J. Mech. Sci. Technol. 34(10), 4295–4305 (2020). https://doi.org/10.1007/s12206-020-0920-y

Pavlov, S.: Sistemy vysokoproizvoditel'nyh vychislenij v 2019–2020 godah: obzor dostizhenij i analiz rynkov. CHast’ V. Sfera PLM, vklyuchaya CAE i EDA (High Performance Computing in 2019–2020: Overview of Advances and Market Analysis. Part V. Scope of PLM, including CAE and EDA). CAD/CAM/CAE Observer (2020). http://www.cadcamcae.lv/N139/04-19.pdf. Accessed 16 Jan 2022

Berselli, G., Bilancia, P., Luzi, L.: Project-based learning of advanced CAD/CAE tools in engineering education. Int. J. Interact. Des. Manuf. (IJIDeM) 14(3), 1071–1083 (2020). https://doi.org/10.1007/s12008-020-00687-4

Polyakov, A.N., Dodorov, A.I.: Metodika vybora tverdotel'nyh konechno-elementnyh modelej nesushchih sistem stankov pri provedenii ih inzhenernogo analiza (Method for selecting solid-state finite element models of machine tool support systems when conducting their engineering analysis). Bulletin of BSTU named after V.G. Shukhov, Belgoroddoi (2019). https://doi.org/10.34031/article_5d07863d89d1e9.79636729

Park, H., Easwaran, A., Andalam, S.: Challenges in digital twin development for cyber-physical production systems. In: Chamberlain, R., Taha, W., Törngren, M. (eds.) CyPhy/WESE -2018. LNCS, vol. 11615, pp. 28–48. Springer, Cham (2019). https://doi.org/10.1007/978-3-030-23703-5_2

Nikitina, I.P., Polyakov, A.N.: Experimental study of double-sided face grinding machine tool. J. Phys. Conf. Ser. 1399(4), 044026 (2019). https://doi.org/10.1088/1742-6596/1399/4/044026

Nikitina, I.P., Polyakov, A.N.: Experimental thermal performance double-sided face grinding machine. In: Radionov, A.A., Gasiyarov, V.R. (eds.) Proceedings of the 7th International Conference on Industrial Engineering (ICIE 2021): Volume I, pp. 134–142. Springer International Publishing, Cham (2022). https://doi.org/10.1007/978-3-030-85233-7_16

Kozhevnikova, M.E., Rotanova, T.A., et al.: Komp'yuternoe modelirovanie ploskih zadach termouprugosti: sravnitel'nyj analiz reshenij v svyazannoj i nesvyazannoj postanovkah (Computer Simulation of Plane Problems of Thermoelasticity: Comparative Analysis of Solutions in Coupled and Uncoupled Statements). Computational Continuum Mechanics, Perm (2017)

Acknowledgments

The study was carried out with financial support from the federal budget in 2021, a grant in the form of a subsidy for the implementation of the program of strategic academic leadership “Priority-2030” under agreements No. 075–15-2021–1171, 075–15-2021–1112.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Nikitina, I.P., Polyakov, A.N. (2023). Method of Simulation of the Thermal Deformation Behavior of Double-Sided Face Grinding Machines. In: Radionov, A.A., Gasiyarov, V.R. (eds) Proceedings of the 8th International Conference on Industrial Engineering. ICIE 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-14125-6_8

Download citation

DOI: https://doi.org/10.1007/978-3-031-14125-6_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-14124-9

Online ISBN: 978-3-031-14125-6

eBook Packages: EngineeringEngineering (R0)