Abstract

Scanning electron microscopy (SEM) is perhaps the first technique a catalyst researcher should use to start characterizing a catalyst. In this chapter, we present an overview of instrumental considerations when studying heterogeneous catalysts via SEM, methods to achieve high resolution for imaging and elemental analysis, and applications and case studies highlighting the use of SEM for the study of catalysts. The SEM images show the morphology of the sample and provide elemental composition and an indication of the uniformity of the sample as well as information on pore structure and particle size at the micron scale. The ability to see the material over this length scale is critical to early identification of issues with catalyst preparation, such as poor distribution of the active components. Using a high-resolution SEM, or when possible, a STEM detector within the SEM, it is possible to achieve resolutions rivaling a TEM. Then it becomes possible to see individual pores, the size and morphology of nanoparticles, and their composition. SEM is also ideally suited to see exposed surface facets in nanoparticles. Sample preparation for SEM is so much easier than a TEM, since the sample can be simply sprinkled on an SEM stub. The disadvantage is that only the surface of the sample is visible. But one can probe deeper by generating cross sections of extrudates. Such cross sections can help in identifying the location of various components, such as, for example, when preparing eggshell morphologies where the active phase is present only in the near-surface region of an extrudate.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Goldstein, J.I., et al.: Scanning Electron Microscopy and X-ray Microanalysis, vol. 2018, 4th edn. Science+Business Media LLC (2018)

Krumeich, F.: SEM: Imaging with Secondary Electrons. Available from: https://www.microscopy.ethz.ch/se.htm. Accessed 2/20/2021

Kuo, W.C.H., Briceno, M., Ozkaya, D.: Final analysis: characterisation of catalysts using secondary and backscattered electron in-lens detectors. Platin. Met. Rev. 58(2), 106–110 (2014)

JEOL. STEM-in-SEM (2020). Available from: https://www.jeolusa.com/RESOURCES/Electron-Optics/Documents-Downloads/stem-in-sem

Terasaki, O., et al.: Novel structural characterisations of insulating and electron beam sensitive materials employing low voltage high resolution scanning electron microscopy. JEOL News. 48(1), 21–31 (2013)

Suga, M., et al.: Recent progress in scanning electron microscopy for the characterization of fine structural details of nano materials. Prog. Solid State Chem. 42(1), 1–21 (2014)

Joy, D.C.: Resolution in low-voltage scanning electron-microscopy. J. Microsc. Oxford. 140, 283–292 (1985)

Peters, K.R.: Collection deficiencies of scanning electron microscopy signal contrasts measured and corrected by differential hysteresis image processing. Scanning. 18(8), 539–555 (1996)

Krumeich, F., et al.: Morphology and topochemical reactions of novel vanadium oxide nanotubes. J. Am. Chem. Soc. 121(36), 8324–8331 (1999)

Michael, J.R.: High resolution at low beam energy in the SEM: resolution measurement of a monochromated SEM. Scanning. 33(3), 147–154 (2011)

Asahina, S., et al.: Direct observation and analysis of yolk-shell materials using low-voltage high-resolution scanning electron microscopy: nanometal-particles encapsulated in metal-oxide, carbon, and polymer. APL Mater. 2(11), 113317 (2014)

Zhu, Y., et al.: Imaging single atoms using secondary electrons with an aberration-corrected electron microscope. Nat. Mater. 8(10), 808–812 (2009)

Yokoi, T.: Characterization of zeolites by advanced SEM/STEM techniques. Hitachi Sci. Instrum. News. 7(September), 7 (2016)

Friel, J.J., Lyman, C.E.: Tutorial review: X-ray map** in electron-beam instruments. Microsc. Microanal. 12(1), 2–25 (2006)

Veisi, H., Mirzaei, A., Mohammadi, P.: Palladium nanoparticles decorated into a biguanidine modified-KIT-5 mesoporous structure: a recoverable nanocatalyst for ultrasound-assisted Suzuki-Miyaura cross-coupling. RSC Adv. 9(71), 41581–41590 (2019)

Sugar, J.D., et al.: Comparison of orientation map** in SEM and TEM. Microsc. Microanal. 26(4), 630–640 (2020)

Burkhardt, U., et al.: Absolute structure from scanning electron microscopy. Sci. Rep. 10(1), 4065 (2020)

Susman, M.D., et al.: Synthesis of NiO crystals exposing stable high-index facets. Angew. Chem. Int. Edit. 59(35), 15119–15123 (2020)

Prieto, G., et al.: Towards stable catalysts by controlling collective properties of supported metal nanoparticles. Nat. Mater. 12(1), 34–39 (2013)

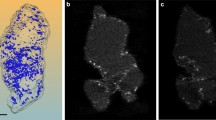

Pham, H., et al.: Using a combination of HAADF and SE imaging to locate Pt nanoparticles within a mesoporous silica diesel oxidation catalyst. Microsc. Microanal. 24(S1), 1700–1701 (2018). https://doi.org/10.1017/S143192761800898X

Somorjai, G.A., Park, J.Y.: Concepts, instruments, and model systems that enabled the rapid evolution of surface science. Surf. Sci. 603(10–12), 1293–1300 (2009)

Zhu, C., et al.: Product-specific active site motifs of Cu for electrochemical CO2 reduction. Chem. 7(2), 406–420 (2021)

Ballestas-Barrientos, A., et al.: Interactions of plasmonic silver nanoparticles with high energy sites on multi-faceted rutile TiO2 photoanodes. ChemCatChem. 12, 469 (2020)

Danilatos, G.D.: Review and outline of environmental SEM at present. J. Microsc. 162, 391–402 (1991)

Greiner, M.T., et al.: Phase coexistence of multiple copper oxides on AgCu catalysts during ethylene epoxidation. ACS Catal. 8(3), 2286–2295 (2018)

Yang, L., et al.: Making a hybrid microfluidic platform compatible for in situ imaging by vacuum-based techniques. J. Vac. Sci. Technol. A. 29(6), 061101 (2011)

Yu, X.-Y.: In situ, in vivo, and in operando imaging and spectroscopy of liquids using microfluidics in vacuum. J. Vac. Sci. Technol. A. 38(4), 040804 (2020)

Kolmakova, N., Kolmakov, A.: Scanning electron microscopy for in situ monitoring of semiconductor−liquid interfacial processes: electron assisted reduction of Ag ions from aqueous solution on the surface of TiO2 rutile nanowire. J. Phys. Chem. C. 114(40), 17233–17237 (2010)

Wang, Z.-J., et al.: The coalescence behavior of two-dimensional materials revealed by multiscale in situ imaging during chemical vapor deposition growth. ACS Nano. 14(2), 1902–1918 (2020)

Acknowledgments

Acquisition of the Hitachi S-5200 was supported by a NSF EPSCOR Infrastructure Improvement grant. Research on the use of mesoporous silica for enhancing catalyst stability was supported by NSF GOALI grant CBET 1707127, and the authors acknowledge funding from the US Department of Energy, Office of Science, Catalysis Science Program grant DE-FG02-05ER15712. We thank Hitachi High Technologies North America for providing us access to the HF-5000 AC-STEM and the SU-9000 high-resolution SEM. The authors wish to thank Professor David Joy and Charlie Lyman for helpful discussions regarding imaging and microanalysis in the SEM and Dr. Frank Krumeich for providing some of the images in Figs. 18.1 and 18.7 in this chapter.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Datye, A., DeLaRiva, A. (2023). Scanning Electron Microscopy (SEM). In: Wachs, I.E., Bañares, M.A. (eds) Springer Handbook of Advanced Catalyst Characterization. Springer Handbooks. Springer, Cham. https://doi.org/10.1007/978-3-031-07125-6_18

Download citation

DOI: https://doi.org/10.1007/978-3-031-07125-6_18

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-07124-9

Online ISBN: 978-3-031-07125-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)