Abstract

The most appropriate separation technique for the processing of solid metal parts with large dimensions is sawing. The cutting tools used in this machining process are exposed to very high mechanical and thermal loads, yet the highest precision, product quality and process stability must be guaranteed. With regard to process optimisation, the prediction of tool failure and the estimation of the remaining useful life is an important goal. In this paper, a first approach is presented to work towards the development of a degradation model for circular saw blades based on monitored process parameters. Such a degradation model could then be used to derive the key objectives presented above. The basis of this analysis is the recording of the sensor signals current, voltage, vibration and sound with a high sampling rate, whereby in the present work the focus will initially be on the first two signals mentioned - current and voltage. These signals were analysed in such a way that key indicators could be derived. These key indicators were then used to carry out initial analyses, which are intended both to increase the understanding of the process and to form the basis for future analyses.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

DIN 8589-0, Manufacturing processes chip removal - part 0: General; classification, subdivision, terms and definitions. Beuth Verlag, Berlin (2003). Qreg

Tönshoff, H.K., Denkena, B.: Basics of Cutting and Abrasive Processes. Springer, Heidelberg (2013)

Tschätsch, H.: Applied Machining Technology. Springer, Heidelberg (2009)

Kuntoglu, M., et al.: A review of indirect tool condition monitoring systems and decision-making methods in turning: critical analysis and trends. MDPI (2020)

Zhou, Y., Sun, W.: Tool wear condition monitoring in milling process based on current sensors. IEEE Access 8, 95491–95502 (2020). https://doi.org/10.1109/ACCESS.2020.2995586

Sevilla-Camacho, P.Y., Robles-Ocampo, J.B., Muñiz-Soria, J., Lee-Orantes, F.: Tool failure detection method for high-speed milling using vibration signal and reconfigurable bandpass digital filtering. Int. J. Adv. Manuf. Technol. 81(5–8), 1187–1194 (2015). https://doi.org/10.1007/s00170-015-7302-0

Tönshoff, H.K., Insaki, I.: Sensors in Manufacturing. Wley-VCH Verlag GmbH (2001)

Ammouri, A.H., Hamade, R.F.: Current rise criterion: a process-independent method for tool-condition monitoring and prognostics. Int. J. Adv. Manuf. Technol. 72(1–4), 509–519 (2014). https://doi.org/10.1007/s00170-014-5679-9

Stavropoulos, P., Papacharalampopoulos, A., Vasiliadis, E., Chryssolouris, G.: Tool wear predictability estimation in milling based on multi-sensorial data. Int. J. Adv. Manuf. Technol. 82(1–4), 509–521 (2015). https://doi.org/10.1007/s00170-015-7317-6

Jahromi, A., Er, M., Li, X., Lim, B.: Sequential fuzzy clustering based dynamic fuzzy neural network for fault diagnosis and prognosis. Neurocomputing 196, 31–41 (2016). https://doi.org/10.1016/j.neucom.2016.02.036

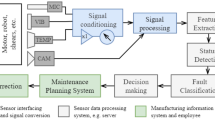

Hinz, M., Brüggemann, D., Bracke, S.: On the application of machine learning techniques in condition monitoring systems of complex machines. In: 14th Probabilistic Safety Assessment and Management Conference - PSAM, Los Angeles (USA)

Hinz, M., Brüggemann, D., Bracke, S.: Framework for customized, machine learning driven condition monitoring system for manufacturing. In: 25th International Conference on Production Research - ICPR, Chicago (USA)

Acknowledgements

The authors thank Christoph Rosebrock, Max Radetzky, Tom Stürwold and Pit Fiur for the contributions. Furthermore, the authors thank the project sponsor ERDF (European Regional Development Fund) and the Ministry of Economic Affairs, Innovation, Digitalization and Energy of the State of North Rhine-Westphalia. The project organization is supported by PTJ (Project Management Jülich).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Brüggemann, D., Kneifel, J., Bracke, S. (2022). Fundamental Analysis of a Circular Metal Sawing Process. In: Gapiński, B., Ciszak, O., Ivanov, V. (eds) Advances in Manufacturing III. MANUFACTURING 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-00805-4_11

Download citation

DOI: https://doi.org/10.1007/978-3-031-00805-4_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-00804-7

Online ISBN: 978-3-031-00805-4

eBook Packages: EngineeringEngineering (R0)