Abstract

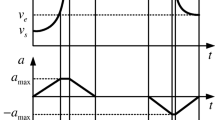

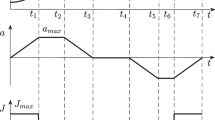

For the successful implementation of innovative automated technological processes, such as high speed machining, 3D laser welding, 3D laser cutting and laser cladding it is necessary to provide highly effective control of the working tool movement speed in multi-axis space of cyber-physical system. A simplified three-interval model S-shaped feedrate profile with smoothly-limited jerk using the sin2 function are proposed. An algorithm for pre-scheduling of the feedrate before the start of motion control, which has no constraints on the number of analyzed blocks and the scheduling execution time is proposed. Modeling the scheduling process on the example of a test trajectory has shown the high efficiency of the proposed model. Reduction of the processing time of the control section of the trajectory by 7.4% to 10.7% in comparison with the Heidenhain iTNC530 system with the same acceleration and jerk limitations are obtained.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Permyakov, A., Dobrotvorskiy, S., Dobrovolska, L., Basova, Y., Ivanova, M.: Computer modeling application for predicting of the passing of the high-speed milling machining hardened steel. In: Ivanov, V., et al. (eds.) DSMIE 2018. LNME, pp. 135–145. Springer, Cham (2019). https://doi.org/10.1007/978-3-319-93587-4_15

Dodok, T., Čuboňová, N., Císar, M., et al.: Influence of CNC milling strategies on complex surface machining. IOP Conf. Ser. Mater. Sci. Eng. 776(1), 012002 (2020). https://doi.org/10.1088/1757-899X/776/1/012002

Plankovskyy, S., Tsegelnyk, Y., Shypul, O., Pankratov, A., Romanova, T.: Cutting irregular objects from the rectangular metal sheet. In: Nechyporuk, M., Pavlikov, V., Kritskiy, D. (eds.) Integrated Computer Technologies in Mechanical Engineering. AISC, vol. 1113, pp. 150–157. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-37618-5_14

Anghel, C., Gupta, K., Jen, T.C.: Analysis and optimization of surface quality of stainless steel miniature gears manufactured by CO2 laser cutting. Optik 203, 164049 (2020). https://doi.org/10.1016/j.ijleo.2019.164049

Bernatskyi, A.V., Berdnikova, O.M., Klochkov, I.M., et al.: Laser welding in different spatial positions of T-joints of austenitic steel. IOP Conf. Ser. Mater. Sci. Eng. 582(1), 012048 (2019). https://doi.org/10.1088/1757-899X/582/1/012048

Plankovskyy, S., Shypul, O., Tsegelnyk, Y., et al.: Simulation of surface heating for arbitrary shape’s moving bodies/sources by using R-functions. Acta Polytechnica 56(6), 472–477 (2016). https://doi.org/10.14311/AP.2016.56.0472

Krol, O., Sokolov, V.: Modeling carrier system dynamics for metal-cutting machines. In: 2018 International Russian Automation Conference (RusAutoCon), pp. 1–5. IEEE, Sochi (2018). https://doi.org/10.1109/RUSAUTOCON.2018.8501799

Chen, Y., Ji, X., Tao, Y., Wei, H.: Look-ahead algorithm with whole S-curve acceleration and deceleration. Adv. Mech. Eng. 5, 974152 (2013). https://doi.org/10.1155/2013/974152

Qin, Q., Huang, J., Yao, J.: A real-time adaptive look-ahead speed control algorithm for FDM-based additive manufacturing technology with Hbot kinematic system. Rapid Prototy** J. 25(6), 1095–1107 (2019). https://doi.org/10.1108/RPJ-11-2018-0291

Plankovskyy, S., Myntiuk, V., Tsegelnyk, Y., Zadorozhniy, S., Kombarov, V.: Analytical methods for determining the static and dynamic behavior of thin-walled structures during machining. In: Shkarlet, S., Morozov, A., Palagin, A. (eds.) MODS 2020. AISC, vol. 1265, pp. 82–91. Springer, Cham (2021). https://doi.org/10.1007/978-3-030-58124-4_8

Petrakov, Y., Shuplietsov, D.: Contour milling programming technology for virtual basing on a CNC machine. Eastern-Eur. J. Enterprise Technol. 98(2/1), 54–60 (2019). https://doi.org/10.15587/1729-4061.2019.162673

Kolar, P., Sulitka, M., Matyska, V., Fojtu, P.: Optimization of five-axis finish milling using a virtual machine tool. MM Sci. J. 2019(05), 3534–3543 (2019). https://doi.org/10.17973/MMSJ.2019_12_2019037

Vovk, A., Sölter, J., Karpuschewski, B.: Finite element simulations of the material loads and residual stresses in milling utilizing the CEL method. Procedia CIRP 87, 539–544 (2020). https://doi.org/10.1016/j.procir.2020.03.005

Jacso, A., Szalay, T., Jauregui, J.C., Resendiz, J.R.: A discrete simulation-based algorithm for the technological investigation of 2.5D milling operations. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 233(1), 78–90 (2019). https://doi.org/10.1177/0954406218757267

Aksonov, Y., Kombarov, V., Fojtů, O., et al.: Investigation of processes in high-speed equipment using CNC capabilities. MM Sci. J. 2019(04), 3271–3276 (2019). https://doi.org/10.17973/MMSJ.2019_11_2019081

Kombarov, V., Sorokin, V., Fojtů, O., et al.: S-curve algorithm of acceleration/deceleration with smoothly-limited jerk in high-speed equipment control tasks. MM Sci. J. 2019(04), 3264–3270 (2019). https://doi.org/10.17973/MMSJ.2019_11_2019080

Erkorkmaz, K., Altintas, Y.: High speed CNC system design. Part I: jerk limited trajectory generation and quintic spline interpolation. Int. J. Mach. Tools Manuf. 41(9), 1323–1345 (2001). https://doi.org/10.1016/S0890-6955(01)00002-5

Liu, Q., Liu, H., Yuan, S.: High accurate interpolation of NURBS tool path for CNC machine tools. Chin. J. Mech. Eng. 29(5), 911–920 (2016). https://doi.org/10.3901/CJME.2016.0407.047

Fan, W., Gao, X.S., Yan, W., Yuan, C.M.: Interpolation of parametric CNC machining path under confined jounce. Int. J. Adv. Manuf. Technol. 62(5), 719–739 (2012). https://doi.org/10.1007/s00170-011-3842-0

Lee, A.C., Lin, M.T., Pan, Y.R., Lin, W.Y.: The feedrate scheduling of NURBS interpolator for CNC machine tools. Comput. Aided Des. 43(6), 612–628 (2011). https://doi.org/10.1016/j.cad.2011.02.014

Ni, H., Yuan, J., Ji, S., et al.: Feedrate scheduling of NURBS interpolation based on a novel jerk-continuous ACC/DEC algorithm. IEEE Access 6, 66403–66417 (2018). https://doi.org/10.1109/ACCESS.2018.2813334

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Kombarov, V., Sorokin, V., Tsegelnyk, Y., Plankovskyy, S., Aksonov, Y., Fojtů, O. (2022). S-Shape Feedrate Scheduling Method with Smoothly-Limited Jerk in Cyber-Physical Systems. In: Cioboată, D.D. (eds) International Conference on Reliable Systems Engineering (ICoRSE) - 2021. ICoRSE 2021. Lecture Notes in Networks and Systems, vol 305. Springer, Cham. https://doi.org/10.1007/978-3-030-83368-8_6

Download citation

DOI: https://doi.org/10.1007/978-3-030-83368-8_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-83367-1

Online ISBN: 978-3-030-83368-8

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)