Abstract

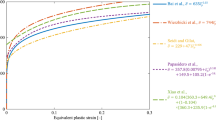

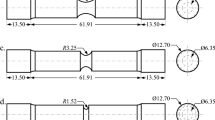

An uncoupled ductile fracture model, based on Mu–Zang model, is extended by incorporating a hydrostatic stress term. An aluminum alloy material (Al 6016-T6) is selected with a series of static ductile fracture tests performed on four different specimens, which can cover a wide range of stress states. A robust simulation-experiment approach is adopted to characterize the correlation between the material’s ductility and distinct stress states. The extended model is then calibrated using least-squares optimization. The resulting 3D fracture surface demonstrates acceptable deviations from the tested data, manifesting a promising capability of the extended model to describe the ductility of the considered material within a wide stress state range. In addition, the comparison against other representative ductile fracture models further confirms a good prediction performance of the model proposed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Li H, Fu MW, Lu J, Yang H (2011) Ductile fracture: experiments and computations. Int J Plast 27(2):147–180

Nahshon K, Hutchinson JW (2008) Modification of the Gurson model for shear failure. Eur J Mech A-Solid 27(1):1–17

Lou Y, Yoon JW, Huh H (2014) Modeling of shear ductile fracture considering a changeable cut-off value for stress triaxiality. Int J Plast 54:56–80

Bai Y, Wierzbicki T (2010) Application of extended Mohr–Coulomb criterion to ductile fracture. Int J Fract 161(1):1–20

Mu L, Jia Z, Ma ZW, Shen FH, Sun YK, Zang Y (2020) A theoretical prediction framework for the construction of a fracture forming limit curve accounting for fracture pattern transition. Int J Plast. https://doi.org/10.1016/j.ijplas.2020.102706

Mu L, Zang Y, Wang Y (2018) Phenomenological uncoupled ductile fracture model considering different void deformation modes for sheet metal forming. Int J Mech Sci 141:408–423

Qian LY, Fang G, Zeng P, Wang Q (2015) Experimental and numerical investigations into the ductile fracture during the forming of flat-rolled 5083-O aluminum alloy sheet. J Mater Process Technol 220:264–275

Hering O, Tekkaya AE (2020) Damage-induced performance variations of cold forged parts. J Mater Process Technol 279:116556

Hu Q, Li X, Han X, Chen J (2017) A new shear and tension based ductile fracture criterion: modeling and validation. Eur J Mech A-Solid 66:370–386

Quach H, Kim JJ, Nguyen DT, Kim YS (2020) Uncoupled ductile fracture criterion considering secondary void band behaviors for failure prediction in sheet metal forming. Int J Mech Sci 169:105297

Roth CC, Mohr D (2016) Ductile fracture experiments with locally proportional loading histories. Int J Plast 79:328–354

Erice B, Roth CC, Mohr D (2018) Stress-state and strain-rate dependent ductile fracture of dual and complex phase steel. Mech Mater 116:11–32

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Jia, Z., Mu, L., Guan, B., Zang, Y. (2021). An Extended Ductile Fracture Prediction Model Considering Hydrostatic Stress and Maximum Shear Stress. In: Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y. (eds) Forming the Future. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-75381-8_133

Download citation

DOI: https://doi.org/10.1007/978-3-030-75381-8_133

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75380-1

Online ISBN: 978-3-030-75381-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)