Abstract

Reliable crack detection and characterization is challenging. Sparsely spaced discrete strain sensors are insensitive to cracks if placed at even modest distances from damage. Improving spatial density of sensors significantly improves reliability in crack detection and characterization, but also significantly increases the costs associated with hardware, sensor installation, and data analysis and management. In the case of very large structures, one-dimensional distributed fiber optic sensors can be applied with reasonable costs, and while they significantly improve reliability in crack detection and characterization, they still cover only one dimension of a structure. In order to address the above challenges, two-dimensional sensor, called sensing sheet, have been developed. It consists of dense array of discrete sensors patterned over thin-film substrate, with integrated computational and power management circuits. The aim of this paper is to present field test performed on the sensing part of sensing sheet and evaluate its performance in crack detection and characterization in real-life settings. Two prototypes of sensing sheet were manufactured and tested. Each of them consisted of eight discrete full-bridge resistive strain sensors. One prototype was installed on the underside of the superstructure of a deck stiffened arch and the other over existing shrinkage cracks on the foundation of Streicker Bridge. The behavior of the sensors was observed under daily temperature change. The test confirmed applicability of sensing sheet in real-life settings and its excellent performance in crack detection and characterization.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

ASCE (2017) Infrastructure report card. ASCE Reston, VA

Cao W, Liu W, Koh CG, Smith IF (2019) Exploring potential benefits of bridge condition assessment in highway operations. In: IABSE congress 2019 (2019). http://infoscience.epfl.ch/record/273255

Farrar CR, Worden K (2007) An introduction to structural health monitoring. Philos Trans Royal Soc A Math Phys Eng Sci 365(1851):303–315

Fu G, Devaraj D (2014) Bridge management using pontis and improved concepts. In: Bridge engineering handbook, 2nd edn. CRC Press, pp 233–246. https://doi.org/10.1201/b16467-10, http://www.crcnetbase.com/doi/abs/10.1201/b16467-10

Kim J, Ahn Y, Yeo H (2016) A comparative study of time-based maintenance and condition-based maintenance for optimal choice of maintenance policy. Struct Infrastruct Eng 12(12):1525–1536

Ni Y, Wong K (2012) Integrating bridge structural health monitoring and condition-based maintenance management. In: 4th International workshop on civil structural health monitoring, pp 6–8

Yao Y, Glisic B (2012) Reliable damage detection and localization using direct strain sensing. Bridge Maintenance, Safety, Management, Resilience and Sustainability pp, pp 714–721

Yao Y, Tung STE, Glisic B (2014) Crack detection and characterization techniques-an overview. Struct Control Health Monit 21(12):1387–1413

Loh KJ, Hou TC, Lynch JP, Kotov NA (2009) Carbon nanotube sensing skinsfor spatial strain and impact damage identification. J Nondestr Eval 28(1):9–25. https://doi.org/10.1007/s10921-009-0043-y, https://doi.org/10.1007/s10921-009-0043-y

Loh KJ, Kim J, Lynch JP, Kam NWS, Kotov NA (2007) Multifunctional layer-by-layer carbon nanotube–polyelectrolyte thin films for strain and corrosion sensing. Smart Mater Struct 16(2):429

Schulz MJ, Sundaresan MJ (2006) Smart sensor system for structural condition monitoring of wind turbines: May 30 2002–April 30 2006. Nat Renew Energy Lab

Laflamme S, Saleem HS, Vasan BK, Geiger RL, Chen D, Kessler MR, Rajan K (2013) Soft elastomeric capacitor network for strain sensing over large surfaces IEEE/ASME Trans Mechatron 18(6):1647–1654

Laflamme S, Ubertini F, Saleem H, D’Alessandro A, Downey A, Ceylan H, Materazzi AL (2014) Dynamic characterization of a soft elastomeric capacitor for structural health monitoring. J Struct Eng 141(8):04014186

Glisic B, Yao Y, Tung STE, Wagner S, Sturm JC, Verma N (2016) Strain sensing sheets for structural health monitoring based on large-area electronics and integrated circuits. Proc IEEE 104(8):1513–1528

Sturm J, Mehlman Y, Aygun LE, Wu C, Zheng Z, Kumar P, Wagner S, Verma N (2019) (keynote) machine learning and high-speed circuitry in thin film transistors for sensor interfacing in hybrid large-area electronic systems. ECS Trans 92(4):121

Ozatay M, Aygun L, Jia H, Kumar P, Mehlman Y, Wu C, Wagner S, Sturm JC, Verma N (2018) Artificial intelligence meets large-scale sensing: using large-area electronics (lae) to enable intelligent spaces. In: 2018 IEEE Custom integrated circuits conference (CICC). IEEE, pp 1–8

Verma N, Hu Y, Huang L, Rieutort-Louis WS, Robinson JS, Moy T, Glisic B, Wagner S, Sturm JC (2015) Enabling scalable hybrid systems: Architectures for exploiting large-area electronics in applications. Proc IEEE 103(4):690–712

Kumar V, Aygun LE, Verma N, Sturm JC, Glisic B (2019) Sensing sheets based on large area electronics for structural health monitoring of bridges. In: Sensors and smart structures technologies for civil, mechanical, and aerospace systems, vol 10970. International Society for Optics and Photonics, p 109702G

Kumar V, Aygun LE, Verma N, Sturm JC, Glisic B (2019) Static and dynamic strain measurements using sensing sheets for damage detection. In: 20th IABSE congress, New York City 2019: the evolving metropolis. International Association for Bridge and Structural Engineering (IABSE), pp 390–396

Yao Y, Glisic B (2015) Detection of steel fatigue cracks with strain sensing sheets based on large area electronics. Sensors (Basel, Switzerland) 15(4):8088–8108. https://doi.org/10.3390/s150408088

Aygun LE, Kumar V, Weaver C, Gerber M, Wagner S, Verma N, Glisic B, Sturm JC (2020) Large-area resistive strain sensing sheet for structural health monitoring. Sensors 20(5):1386

Q-flex inc. https://www.qflexinc.com/. Accessed 21 Dec 2020

Acknowledgements

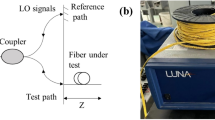

The authors would like to acknowledge the help of Dr. John Reilly in fiber-optic data acquisition and Gabbie Acot in the field measurements.

Funding

This research was supported in part by Princeton University and in part by the USDOT OST-R UTC Program, grant no. 69A3551847102, enabled through the Center for Advanced Infrastructure and Transportation (CAIT) at Rutgers University (subcontract agreement # 0615).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Kumar, V. et al. (2021). Field Evaluation of Sensing Sheet Prototype Exposed to Cracking. In: Rainieri, C., Fabbrocino, G., Caterino, N., Ceroni, F., Notarangelo, M.A. (eds) Civil Structural Health Monitoring. CSHM 2021. Lecture Notes in Civil Engineering, vol 156. Springer, Cham. https://doi.org/10.1007/978-3-030-74258-4_62

Download citation

DOI: https://doi.org/10.1007/978-3-030-74258-4_62

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-74257-7

Online ISBN: 978-3-030-74258-4

eBook Packages: EngineeringEngineering (R0)