Abstract

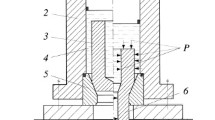

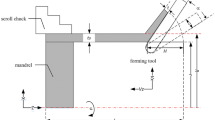

In gearboxes, drives or mechanical devices, there are many hollow transmission parts, which are usually made by forging technology from solid billet and then finished by cutting process. Such technology causes waste of forming energy and materials due to the removal of large quantities of excess metals. The volume of material, that needs to remove, can reach up to 35% of billet volume. In order to save time and effectively making of parts, the hollow billets such as tubes are proposed to use and the technology undergoes the main tasks: first is heating of billet to achieve high temperature, then local upsetting of tube to create an appropriate intermediate billet, and after that forging in closed die. However, the upsetting of tube in hot state is often difficult because the tube is unstable. This leads to low upsetting ratio and appearance of folding defects in the billet. To avoid the instability of tube billet during deformation, it is necessary to calculate the suitable initial dimensions of tube billet and determine the appropriate shape of punch (upper die). This paper presents the research results to determine the time, which the billet is destabilized depending on the ratios height/diameter and thickness/diameter of billet based on numerical simulation. With the target of strain bigger than 40% in the thickness of tube, this research also deals with development of a model for tube upsetting with conical punch, establishment of the relationship between the strain depending on billet geometry and tilt angle of punch based on numerical simulation and experiments.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Politis, N.J., Politis, D.J., Davies, C.M., Lin, J., Dean, T.A.: An experimental and numerical investigation into forming force reduction in precision gear forging. Key Eng. Mater. 623, 165–173 (2017)

Poursina, M., Parvizian, J.: Simulation of folding defect in forging, Nimiform pp. 486–491 (2004)

Su, Y.L., Yang, W.Z., Wang, C.P.: Upsetting process analysis and numerical simulation of metal pipe’s end. Appl. Mech. Mater. 364, 488–492 (2013)

Li, Y., Onodera, E., Chiba, A.: Friction coefficient in hot compression of cylindrical sample. Mater. Trans. 51(7), 1210–1215 (2010)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Trung, N.D., Linh, P.T.H. (2021). Research on the Effect of Geometric Parameters of Billet and Punch on Upsetting Technology of Hollow Transmission Details. In: Long, B.T., Kim, YH., Ishizaki, K., Toan, N.D., Parinov, I.A., Vu, N.P. (eds) Proceedings of the 2nd Annual International Conference on Material, Machines and Methods for Sustainable Development (MMMS2020). MMMS 2020. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-69610-8_36

Download citation

DOI: https://doi.org/10.1007/978-3-030-69610-8_36

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-69609-2

Online ISBN: 978-3-030-69610-8

eBook Packages: EngineeringEngineering (R0)