Abstract

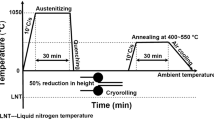

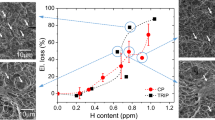

During the last few decades, keen attention has been paid to the advanced steels with the ultra-fine-grained (UFG) microstructure manufactured by severe plastic deformation (SPD) techniques. Although these materials often demonstrate prominent mechanical properties, the detrimental environmentally induced effects, such as hydrogen embrittlement (HE), which may appear during their service life, have been just scarcely studied. In particular, the influence of the hydrogen concentration and strain rate, which are among the main factors controlling HE, in general, has not been considered in UFG ferritic steels as yet. Thus, the objective of the present study was to examine the effect of these factors on the mechanical behaviour and fracture mode of the low-alloy steel processed by ECAP in comparison with the conventionally fabricated counterparts. The ECAPed and as-received specimens of the low-alloy steel grade 09G2S were cathodically hydrogen charged at different current densities and then subjected to tensile testing at two different strain rates. The diffusible hydrogen concentration in the specimens before tensile testing was assessed by the hot extraction method. After hydrogen charging both as-received and ECAPed specimens demonstrate HE the extent of which increases with the increasing hydrogen concentration and decreasing strain rate. It is found that the ECAPed steel occludes much higher hydrogen concentration than the as-received one. At the given hydrogen concentration, the ECAPed specimens demonstrate stronger hydrogen-induced ductility loss as well as a fundamentally different fracture mode in comparison to the as-received counterparts.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Valiev, R.: Nanostructuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 3, 511–516 (2004). https://doi.org/10.1038/nmat1180

Azushima, A., et al.: Severe plastic deformation (SPD) processes for metals. CIRP Ann. Manuf. Technol. 57, 716–735 (2008). https://doi.org/10.1016/j.cirp.2008.09.005

Khafizova, E., et al.: Microstructure, strength and fatigue of an ultrafine-grained Al-Cu-Mg alloy. Mater. Phys. Mech. 24, 232–241 (2015)

Sabirov, I., et al.: Effect of equal channel angular pressing on the fracture behavior of commercially pure titanium. Metall. Mater. Trans. A 41, 727–733 (2010). https://doi.org/10.1007/s11661-009-0111-z

Vinogradov, A., Serebryany, V.N., Dobatkin, S.V.: Tailoring microstructure and properties of fine grained magnesium alloys by severe plastic deformation. Adv. Eng. Mater. 20, 1–22 (2018). https://doi.org/10.1002/adem.201700785

Hohenwarter, A., Pippan, R.: Fracture of ECAP-deformed iron and the role of extrinsic toughening mechanisms. Acta Mater. 61, 2973–2983 (2013). https://doi.org/10.1016/j.actamat.2013.01.057

Dobatkin, S., Odessky, P.D., Shagalina, S.V.: Ultrafine grained low carbon steels processed by severe plastic deformation. Mater. Sci. Forum. 584–586, 623–30 (2008). https://doi.org/10.4028/www.scientific.net/MSF.584-586.623

Merson, E.D., et al.: Effect of fracture mode on acoustic emission behavior in the hydrogen embrittled low-alloy steel. Eng. Fract. Mech. 210, 342–357 (2019). https://doi.org/10.1016/j.engfracmech.2018.05.026

Estrin, Y., Vinogradov, A.: Extreme grain refinement by severe plastic deformation: a wealth of challenging science. Acta Mater. 61, 782–817 (2013). https://doi.org/10.1016/j.actamat.2012.10.038

Vinogradov, A.: Mechanical properties of ultrafine-grained metals: new challenges and perspectives. Adv. Eng. Mater. 17, 1710–1722 (2015). https://doi.org/10.1002/adem.201500177

Soleimani, F., Kazeminezhad, M.: Synergistic strengthening by severe plastic deformation and post-heat treatment of a low-carbon steel. Steel Res. Int. 89, 1–10 (2018). https://doi.org/10.1002/srin.201700548

Mine, Y., Matsumoto, S., Horita, Z.: Strengthening and hydrogen embrittlement of ultrafine-grained Fe–0.01mass% C alloy processed by high-pressure torsion. Corros. Sci. 53, 2969–2977 (2011). https://doi.org/10.1016/j.corsci.2011.05.052

Robertson, I.M., et al.: Hydrogen embrittlement understood. Metall. Mater. Trans. A 46, 2323–2341 (2015). https://doi.org/10.1007/s11661-015-2836-1

Lynch, S.P.: Hydrogen embrittlement phenomena and mechanisms. Corros. Rev. 30, 63–133 (2012). https://doi.org/10.1515/corrrev-2012-0502

Astafurova, E.G., et al.: hydrogen embrittlement of austenitic stainless steels with ultrafine-grained structures of different morphologies. Phys. Mesomech. 22, 313–326 (2019). https://doi.org/10.1134/s1029959919040076

Merson, E.D., et al.: Effect of equal-channel angular pressing (ECAP) and current density of cathodic hydrogen charging on hydrogen trap** in the low-alloy steel. Lett. Mater. 10, 152–157 (2020)

Raab, G.I. et al.: Long-length ultrafine-grained titanium rods produced by ECAP- conform. Mater. Sci. Forum. 584-586PA, 80–85 (2008). https://doi.org/10.4028/www.scientific.net/msf.584-586.80

Merson, E.D., et al.: Quasi-cleavage hydrogen-assisted cracking path investigation by fractographic and side surface observations. Eng. Fract. Mech. 214, 177–193 (2019). https://doi.org/10.1016/j.engfracmech.2019.04.042

Merson, E.D., et al.: About the nature of quasi-cleavage in low-carbon steel embrittled with hydrogen. Met. Sci. Heat Treat. 61, 191–195 (2019). https://doi.org/10.1007/s11041-019-00399-x

Merson, E., et al.: Quantitative characterization of cleavage and hydrogen-assisted quasi-cleavage fracture surfaces with the use of confocal laser scanning microscopy. Mater. Sci. Eng. A 665, 35–46 (2016). https://doi.org/10.1016/j.msea.2016.04.023

Merson, E., et al.: Application of acoustic emission method for investigation of hydrogen embrittlement mechanism in the low-carbon steel. J. Alloys Compd. 645, S460–S463 (2015). https://doi.org/10.1016/j.jallcom.2014.12.083

Acknowledgements

The authors appreciate the help of the research team of Prof. R. Z: Valiev (Ufa State Aviation Technical University) for providing the ECAPed material.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Merson, E.D., Myagkikh, P.N., Klevtsov, G.V., Merson, D.L., Vinogradov, A. (2021). Effect of Hydrogen Concentration and Strain Rate on Hydrogen Embrittlement of Ultra-Fine-Grained Low-Carbon Steel. In: Polyanskiy, V.A., Belyaev, A.K. (eds) Advances in Hydrogen Embrittlement Study. Advanced Structured Materials, vol 143. Springer, Cham. https://doi.org/10.1007/978-3-030-66948-5_10

Download citation

DOI: https://doi.org/10.1007/978-3-030-66948-5_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-66947-8

Online ISBN: 978-3-030-66948-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)