Abstract

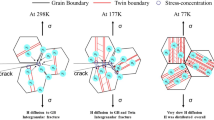

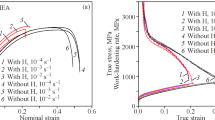

Here, we present a review of the hydrogen embrittlement behavior of face-centered cubic (FCC) alloys with short-range order (SRO) of solute atoms. In this paper, three types of FCC alloys are introduced: Fe–Mn–C austenitic steels, high-nitrogen steels, and CoCrFeMnNi high-entropy alloys. The Fe–Mn–C austenitic steels show dynamic strain aging associated with Mn–C SRO, which causes deformation localization and acceleration of premature fracture even without hydrogen effects. The disadvantageous effect of dynamic strain aging on ductility, which is associated with the deformation localization, amplify plasticity-assisted hydrogen embrittlement. Cr–N and Co–Cr–Ni SRO effects in high-nitrogen austenitic steels and high-entropy alloys enhance the dislocation planarity, which causes stress concentration in the grain interior and near the grain boundaries. The stress concentration coupled with hydrogen effects causes quasi-cleavage and intergranular fractures.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Notes

References

Zhang, L., Wen, M., Imade, M., Fukuyama, S., Yokogawa, K.: Effect of nickel equivalent on hydrogen gas embrittlement of austenitic stainless steels based on type 316 at low temperatures. Acta Mater. 56(14), 3414–3421 (2008). https://doi.org/10.1016/j.actamat.2008.03.022

Omura, T., Nakamura, J., Hirata, H., Jotoku, K., Ueyama, M., Osuki, T., Terunuma, M.: Effect of surface hydrogen concentration on hydrogen embrittlement properties of stainless steels and Ni based alloys. ISIJ Int. 56(3), 405–412 (2016). https://doi.org/10.2355/isi**ternational.ISIJINT-2015-268

Izawa, C., Wagner, S., Deutges, M., Martin, M., Weber, S., Pargeter, R., Michler, T., Uchida, H.-H., Gemma, R., Pundt, A.: Relationship between hydrogen embrittlement and M\(_{\rm {d}30}\) temperature: prediction of low-nickel austenitic stainless steel’s resistance. Int. J. Hydr. Energy 44(45), 25064–25075 (2019). https://doi.org/10.1016/j.ijhydene.2019.07.179

Koyama, M., Ogawa, T., Yan, D., Matsumoto, Y., Tasan, C.C., Takai, K., Tsuzaki, K.: Hydrogen desorption and cracking associated with martensitic trans-formation in Fe–Cr–Ni-Based austenitic steels with different carbon contents. Int. J. Hydr. Energy 42(42), 26423–26435 (2017). https://doi.org/10.1016/j.ijhydene.2017.08.209

Teus, S.M., Shyvanyuk, V.N., Gavriljuk, V.G.: Hydrogen-induced \( {\gamma }\rightarrow {\varepsilon }\) trans-formation and the role of \({\varepsilon }\)-martensite in hydrogen embrittlement of austenit-ic steels. Mater. Sci. Eng. A 497(1), 290–294 (2008). https://doi.org/10.1016/j.msea.2008.07.003

Chun, Y.S., Kim, J.S., Park, K.-T., Lee, Y.-K., Lee, C.S.: Role of \(\rm {\varepsilon }\) martensite in tensile properties and hydrogen degradation of high-Mn steels. Mater. Sci. Eng. A 533, 87–95 (2012). https://doi.org/10.1016/j.msea.2011.11.039

Koyama, M., Tasan, C.C., Tsuzaki, K.: Overview of metastability and compositional complexity effects for hydrogen-resistant iron alloys: inverse austenite stability effects. Eng. Fract. Mech. 214, 123–133 (2019). https://doi.org/10.1016/j.engfracmech.2019.03.049

Koyama, M., Okazaki, S., Sawaguchi, T., Tsuzaki, K.: Hydrogen embrittlement susceptibility of Fe–Mn binary alloys with high Mn content: effects of stable and metastable \(\rm {\varepsilon }\)-martensite, and Mn concentration. Metall. Mater. Trans. A 47(6), 2656–2673 (2016). https://doi.org/10.1007/s11661-016-3431-9

Gibbs, P.J., Hough, P.D., Thürmer, K., Somerday, B.P., San Marchi, C., Zimmerman, J.A.: Stacking fault energy based alloy screening for hydrogen compatibility. JOM 72(5), 1982–1992 (2020). https://doi.org/10.1007/s11837-020-04106-7

Symons, D.M.: Hydrogen embrittlement of Ni–Cr–Fe alloys. Metall. Mater. Trans. A 28(3), 655–663 (1997). https://doi.org/10.1007/s11661-997-0051-4

Dastur, Y.N., Leslie, W.C.: Mechanism of work hardening in Hadfield manganese steel. Metall. Trans. A 12(5), 749–759 (1981). https://doi.org/10.1007/BF02648339

Koyama, M., Shimomura, Y., Chiba, A., Akiyama, E., Tsuzaki, K.: Room-temperature blue brittleness of Fe-Mn-C austenitic steels. Scr. Mater. 141, 20–23 (2017). https://doi.org/10.1016/j.scriptamat.2017.07.017

Owen, W.S., Grujicic, M.: Strain aging of austenitic Hadfield manganese steel. Acta Mater. 47(1), 111–126 (1998). https://doi.org/10.1016/S1359-6454(98)00347-4

Lee, S.-J., Kim, J., Kane, S.N., Cooman, B.C.D.: On the origin of dynamic strain aging in twinning-induced plasticity steels. Acta Mater. 59(17), 6809–6819 (2011). https://doi.org/10.1016/j.actamat.2011.07.040

Koyama, M., Akiyama, E., Tsuzaki, K.: Hydrogen-induced delayed fracture of a Fe-22Mn-0.6C steel pre-strained at different strain rates. Scr. Mater. 66(11), 947–950 (2012). https://doi.org/10.1016/j.scriptamat.2012.02.040

Koyama, M., Akiyama, E., Tsuzaki, K.: Effects of static and dynamic strain aging on hydrogen embrittlement in TWIP steels containing Al. ISIJ Int. 53(7), 1268–1274 (2013). https://doi.org/10.2355/isi**ternational.53.1268

Michler, T., San Marchi, C., Naumann, J., Weber, S., Martin, M.: Hydrogen environment embrittlement of stable austenitic steels. Int. J. Hydr. Energy 37(21), 16231–16246 (2012). https://doi.org/10.1016/j.ijhydene.2012.08.071

Koyama, M., Akiyama, E., Lee, Y.-K., Raabe, D., Tsuzaki, K.: Overview of hydrogen embrittlement in high-Mn steels. Int. J. Hydr. Energy 42(17), 12706–12723 (2017). https://doi.org/10.1016/j.ijhydene.2017.02.214

Tomota, Y., **a, Y., Inoue, K.: Mechanism of low temperature brittle fracture in high nitrogen bearing austenitic steels. Acta Mater. 46(5), 1577–1587 (1998). https://doi.org/10.1016/S1359-6454(97)00350-9

Habib, K., Koyama, M., Tsuchiyama, T., Noguchi, H.: Visualization of dislocations through electron channeling contrast imaging at fatigue crack tip, interacting with pre-existing dislocations. Mater. Res. Lett. 6(1), 61–66 (2018). https://doi.org/10.1080/21663831.2017.1392370

Koyama, M., Habib, K., Masumura, T., Tsuchiyama, T., Noguchi, H.: Gaseous hydrogen embrittlement of a Ni-free austenitic stainless steel containing 1 mass% nitrogen: effects of nitrogen-enhanced dislocation planarity. Int. J. Hydr. Energy 45(16), 10209–10218 (2020). https://doi.org/10.1016/j.ijhydene.2020.02.014

Michler, T., Naumann, J.: Hydrogen embrittlement of Cr-Mn-N-austenitic stainless steels. Int. J. Hydr. Energy 35(3), 1485–1492 (2010). https://doi.org/10.1016/j.ijhydene.2009.10.050

Karaman, I., Sehitoglu, H., Maier, H.J., Chumlyakov, Y.I.: Competing mechanisms and modeling of deformation in austenitic stainless steel single crystals with and without nitrogen. Acta Mater. 49(19), 3919–3933 (2001). https://doi.org/10.1016/S1359-6454(01)00296-8

Oda, K., Kondo, N., Shibata, K.: X-ray absorption fine structure analysis of interstitial (C, N)-substitutional (Cr) complexes in austenitic stainless steels. ISIJ Int. 30(8), 625–631 (1990). https://doi.org/10.2355/isi**ternational.30.625

Koyama, M., Sawaguchi, T., Tsuzaki, K.: Overview of dynamic strain aging and associated phenomena in fe-mn-c austenitic steels. ISIJ Int. 58(8), 1383–1395 (2018). https://doi.org/10.2355/isi**ternational.ISIJINT-2018-237

Koyama, M., Sawaguchi, T., Lee, T., Lee, C.S., Tsuzaki, K.: Work hardening associated with \(\rm {\varepsilon }\)-martensitic transformation, deformation twinning and dynamic strain aging in Fe-17Mn-0.6C and Fe-17Mn-0.8C TWIP steels. Mater. Sci. Eng. A 528(24), 7310–7316 (2011). https://doi.org/10.1016/j.msea.2011.06.011

Oh, S.-K., Kilic, M.E., Seol, J.-B., Hong, J.-S., Soon, A., Lee, Y.-K.: The mechanism of dynamic strain aging for type A serrations in tensile flow curves of Fe-18Mn-0.55C (wt.%) twinning-induced plasticity steel. Acta Mater. 188, 366–375 (2020). https://doi.org/10.1016/j.actamat.2020.02.020

Canadinc, D., Efstathiou, C., Sehitoglu, H.: On the negative strain rate sensitivity of Hadfield steel. Scr. Mater. 59(10), 1103–1106 (2008). https://doi.org/10.1016/j.scriptamat.2008.07.027

Chen, L., Kim, H.-S., Kim, S.-K., De Cooman, B.C.: Localized Deformation due to Portevin–LeChatelier Effect in 18Mn & ndash;0.6C TWIP austenitic steel. ISIJ Int. 47(12), 1804–1812 (2007). https://doi.org/10.2355/isi**ternational.47.1804

Renard, K., Ryelandt, S., Jacques, P.J.: Characterisation of the Portevin-Le Châtelier effect affecting an austenitic TWIP steel based on digital image cor-relation. Mater. Sci. Eng. A 527(12), 2969–2977 (2010). https://doi.org/10.1016/j.msea.2010.01.037

Yu, H.-Y., Lee, S.-M., Nam, J.-H., Lee, S.-J., Fabrègue, D., Park, M.-h., Tsuji, N., Lee, Y.-K.: Post-uniform elongation and tensile fracture mechanisms of Fe-18Mn-0.6C-xAl twinning-induced plasticity steels. Acta Mater. 131, 435–444 (2017). https://doi.org/10.1016/j.actamat.2017.04.011

Najam, H., Koyama, M., Bal, B., Akiyama, E., Tsuzaki, K.: Strain rate and hydrogen effects on crack growth from a notch in a Fe-high-Mn steel containing 1.1 wt% solute carbon. Int. J. Hydr. Energy 45(1), 1125–1139 (2020). https://doi.org/10.1016/j.ijhydene.2019.10.227

Hutchinson, B., Ridley, N.: On dislocation accumulation and work hardening in Hadfield steel. Scr. Mater. 55(4), 299–302 (2006). https://doi.org/10.1016/j.scriptamat.2006.05.002

Hordon, M.J., Averbach, B.L.: X-ray measurements of dislocation density in deformed Copper and Aluminum single crystals. Acta Metall. 9(3), 237–246 (1961). https://doi.org/10.1016/0001-6160(61)90073-6

Glarebrough, L.M., Hargreaves, M.E., West, G.W.: The density of dislocations in compressed copper. Acta Metall. 5(12), 738–740 (1957). https://doi.org/10.1016/0001-6160(57)90076-7

Clarebrough, L.M., Hargreaves, M.E., West, G.W., Head, A.K., Mott, N.F.: The energy stored in fatigued metals. Proc. R. Soc. Lond. A Math Phys. Sci. 242(1229), 160–166 (1957). https://doi.org/10.1098/rspa.1957.0164

Shintani, T., Murata, Y.: Evaluation of the dislocation density and dislocation character in cold rolled Type 304 steel determined by profile analysis of X-ray diffraction. Acta Mater. 59(11), 4314–4322 (2011). https://doi.org/10.1016/j.actamat.2011.03.055

Dini, G., Ueji, R., Najafizadeh, A., Monir-Vaghefi, S.M.: Flow stress analysis of TWIP steel via the XRD measurement of dislocation density. Mater. Sci. Eng. A 527(10), 2759–2763 (2010). https://doi.org/10.1016/j.msea.2010.01.033

Tuğuca, I.B., Koyama, M., Bal, B., Canadinc, D., Akiyama, E., Tsuzaki, K.: High-concentration carbon assists plasticity-driven hydrogen embrittlement in a Fe-high Mn steel with a relatively high stacking fault energy. Mater. Sci. Eng. A 717, 78–84 (2018). https://doi.org/10.1016/j.msea.2018.01.087

Tuğluca, I.B., Koyama, M., Shimomura, Y., Bal, B., Canadinc, D., Akiyama, E., Tsuzaki, K.: Lowering strain rate simultaneously enhances carbon- and hydrogen-induced mechanical degradation in an Fe-33Mn-1.1C Steel. Metall. Mater. Trans. A 50(3), 1137–1141 (2019). https://doi.org/10.1007/s11661-018-5080-7

Bouaziz, O., Allain, S., Scott, C.P., Cugy, P., Barbier, D.: High manganese austenitic twinning induced plasticity steels: a review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 15(4), 141–168 (2011). https://doi.org/10.1016/j.cossms.2011.04.002

Chowdhury, P., Canadinc, D., Sehitoglu, H.: On deformation behavior of Fe-Mn based structural alloys. Mater. Sci. Eng. R 122, 1–28 (2017). https://doi.org/10.1016/j.mser.2017.09.002

Liang, Z.Y., Wang, X., Huang, W., Huang, M.X.: Strain rate sensitivity and evolution of dislocations and twins in a twinning-induced plasticity steel. Acta Mater. 88, 170–179 (2015). https://doi.org/10.1016/j.actamat.2015.01.013

Koyama, M., Akiyama, E., Sawaguchi, T., Raabe, D., Tsuzaki, K.: Hydrogen-induced cracking at grain and twin boundaries in an Fe-Mn-C austenitic steel. Scr. Mater. 66(7), 459–462 (2012). https://doi.org/10.1016/j.scriptamat.2011.12.015

Koyama, M., Akiyama, E., Tsuzaki, K., Raabe, D.: Hydrogen-assisted failure in a twinning-induced plasticity steel studied under in situ hydrogen charging by electron channeling contrast imaging. Acta Mater. 61(12), 4607–4618 (2013). https://doi.org/10.1016/j.actamat.2013.04.030

Ryu, J.H., Kim, S.K., Lee, C.S., Suh, D.-W., Bhadeshia, H.K.D.H.: Effect of aluminium on hydrogen-induced fracture behaviour in austenitic Fe–Mn–C steel. Proc. R. Soc. A: Mathematical, Physical and Engineering Sciences 469(2149), 20120458 (2013). https://doi.org/10.1098/rspa.2012.0458

Koyama, M., Bashir, A., Rohwerder, M., Merzlikin, S.V., Akiyama, E., Tsuzaki, K., Raabe, D.: Spatially and kinetically resolved map** of hydrogen in a twinning-induced plasticity steel by use of scanning kelvin probe force microscopy. J. Electrochem. Soc. 162(12), C638–C647 (2015). https://doi.org/10.1149/2.0131512jes

So, K.H., Kim, J.S., Chun, Y.S., Park, K.-T., Lee, Y.-K., Lee, C.S.: Hydrogen delayed fracture properties and internal hydrogen behavior of a Fe-18Mn-1.5Al-0.6C TWIP Steel. ISIJ Int. 49(12), 1952–1959 (2009). https://doi.org/10.2355/isi**ternational.49.1952

Du, Y.A., Ismer, L., Rogal, J., Hickel, T., Neugebauer, J., Drautz, R.: First-principles study on the interaction of H interstitials with grain boundaries in \(\rm {\alpha }\)- and \(\rm {\gamma }\)-Fe. Phys. Rev. B 84(14), 144121 (2011). https://doi.org/10.1103/PhysRevB.84.144121

Mahajan, S., Chin, G.Y.: Twin-slip, twin-twin and slip-twin interactions in Co-8 wt.% Fe alloy single crystals. Acta Metall. 21(2), 173–179 (1973). https://doi.org/10.1016/0001-6160(73)90059-X

Rémy, L.: Twin-slip interaction in f.c.c. crystals. Acta Metall. 25(6), 711–714 (1977). https://doi.org/10.1016/0001-6160(77)90013-X

Wang, Y.B., Sui, M.L.: Atomic-scale in situ observation of lattice dislocations passing through twin boundaries. Appl. Phys. Lett. 94(2), 021909 (2009). https://doi.org/10.1063/1.3072801

Bal, B., Koyama, M., Gerstein, G., Maier, H.J., Tsuzaki, K.: Effect of strain rate on hydrogen embrittlement susceptibility of twinning-induced plasticity steel pre-charged with high-pressure hydrogen gas. Int. J. Hydr. Energy 41(34), 15362–15372 (2016). https://doi.org/10.1016/j.ijhydene.2016.06.259

Koyama, M., Rohwerder, M., Tasan, C.C., Bashir, A., Akiyama, E., Takai, K., Raabe, D., Tsuzaki, K.: Recent progress in microstructural hydrogen map** in steels: quantification, kinetic analysis, and multi-scale characterisation. Mater. Sci. Technol. 33(13), 1481–1496 (2017). https://doi.org/10.1080/02670836.2017.1299276

Masumura, T., Seto, Y., Tsuchiyama, T., Kimura, K.: Work-hardening mechanism in high-nitrogen austenitic stainless steel. Mater. Trans. 61(4), 678–684 (2020). https://doi.org/10.2320/matertrans.H-M2020804

Terazawa, Y., Ando, T., Tsuchiyama, T., Takaki, S.: Relationship between work hardening behaviour and deformation structure in Ni-free high nitro-gen austenitic stainless steels. Steel Res. Int. 80(7), 473–476 (2009). https://doi.org/10.2374/sri09sp039

Tsuchiyama, T., Fujii, Y., Terazawa, Y., Nakashima, K., Ando, T., Takaki, S.: Factors inducing intergranular fracture in nickel-free high nitrogen austen-itic stainless steel produced by solution nitriding. ISIJ Int. 48(6), 861–867 (2008). https://doi.org/10.2355/isi**ternational.48.861

Kubota, S., **a, Y., Tomota, Y.: Work-hardening behavior and evolution of dislocation-microstructures in high-nitrogen bearing austenitic steels. ISIJ Int. 38(5), 474–481 (1998). https://doi.org/10.2355/isi**ternational.38.474

Yeh, J.-W., Chen, S.-K., Lin, S.-J., Gan, J.-Y., Chin, T.-S., Shun, T.-T., Tsau, C.-H., Chang, S.-Y.: Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6(5), 299–303 (2004). https://doi.org/10.1002/adem.200300567

Cantor, B.: Multicomponent and high entropy alloys. Entropy 16(9), 4749 (2014)

Gludovatz, B., Hohenwarter, A., Catoor, D., Chang, E.H., George, E.P., Ritchie, R.O.: A fracture-resistant high-entropy alloy for cryogenic applications. Science 345(6201), 1153–1158 (2014). https://doi.org/10.1126/science.1254581

Yao, M.J., Pradeep, K.G., Tasan, C.C., Raabe, D.: A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility. Scr. Mater. 72–73, 5–8 (2014). https://doi.org/10.1016/j.scriptamat.2013.09.030

Ding, J., Yu, Q., Asta, M., Ritchie, R.O.: Tunable stacking fault energies by tailoring local chemical order in CrCoNi medium-entropy alloys. Proc. Natl. Acad. Sci. USA 115(36), 8919–8924 (2018). https://doi.org/10.1073/pnas.1808660115

Zhang, R., Zhao, S., Ding, J., Chong, Y., Jia, T., Ophus, C., Asta, M., Ritchie, R.O., Minor, A.M.: Short-range order and its impact on the CrCoNi medium-entropy alloy. Nature 581(7808), 283–287 (2020). https://doi.org/10.1038/s41586-020-2275-z

Nygren, K.E., Bertsch, K.M., Wang, S., Bei, H., Nagao, A., Robertson, I.M.: Hydrogen embrittlement in compositionally complex FeNiCoCrMn FCC solid solution alloy. Curr. Opin. Solid State Mater. Sci. 22(1), 1–7 (2018). https://doi.org/10.1016/j.cossms.2017.11.002

Ichii, K., Koyama, M., Tasan, C.C., Tsuzaki, K.: Comparative study of hydro-gen embrittlement in stable and metastable high-entropy alloys. Scr. Mater. 150, 74–77 (2018). https://doi.org/10.1016/j.scriptamat.2018.03.003

Zhao, Y., Lee, D.-H., Seok, M.-Y., Lee, J.-A., Phaniraj, M.P., Suh, J.-Y., Ha, H.-Y., Kim, J.-Y., Ramamurty, U., Jang, J.-i.: Resistance of CoCrFeMnNi high-entropy alloy to gaseous hydrogen embrittlement. Scr. Mater. 135, 54–58 (2017). https://doi.org/10.1016/j.scriptamat.2017.03.029

Ichii, K., Koyama, M., Tasan, C.C., Tsuzaki, K.: Localized plasticity and associated cracking in stable and metastable high-entropy alloys pre-charged with hydrogen. Procedia Struct. Integr. 13, 716–721 (2018). https://doi.org/10.1016/j.prostr.2018.12.119

Park, I.-J., Lee, S.-M., Jeon, H.-h., Lee, Y.-K.: The advantage of grain refinement in the hydrogen embrittlement of Fe-18Mn-0.6C twinning-induced plasticity steel. Corros. Sci. 93, 63–69 (2015). https://doi.org/10.1016/j.corsci.2015.01.012

Zan, N., Ding, H., Guo, X., Tang, Z., Bleck, W.: Effects of grain size on hydrogen embrittlement in a Fe-22Mn-0.6C TWIP steel. Int. J. Hydr. Energy 40(33), 10687–10696 (2015). https://doi.org/10.1016/j.ijhydene.2015.06.112

Koyama, M., Ichii, K., Tsuzaki, K.: Grain refinement effect on hydrogen embrittlement resistance of an equiatomic CoCrFeMnNi high-entropy alloy. Int. J. Hydr. Energy 44(31), 17163–17167 (2019). https://doi.org/10.1016/j.ijhydene.2019.04.280

Acknowledgements

This work was financially supported by JSPS KAKENHI (JP16H06365 and JP20H02457) and the Japan Science and Technology Agency (JST) (Grant no. 20100113) under the Industry-Academia Collaborative R&D Program.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Koyama, M. et al. (2021). Potential Effects of Short-Range Order on Hydrogen Embrittlement of Stable Austenitic Steels—A Review. In: Polyanskiy, V.A., Belyaev, A.K. (eds) Advances in Hydrogen Embrittlement Study. Advanced Structured Materials, vol 143. Springer, Cham. https://doi.org/10.1007/978-3-030-66948-5_1

Download citation

DOI: https://doi.org/10.1007/978-3-030-66948-5_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-66947-8

Online ISBN: 978-3-030-66948-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)