Abstract

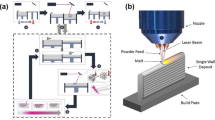

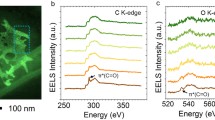

Laser processing technologies for micro-/nanostructuring of electrode materials have a great potential in improving the electrochemical performance and operational lifetime of lithium-ion cells. Different types of laser structuring were used on different surfaces such as metallic current collectors and thin or thick film electrodes. For thin metallic current collector foils, at anode and cathode sides, the self-organized structuring by laser-induced periodical surface structures and laser interference methods were successfully applied for improving electrode film adhesion and cell impedance. For thin and thick film electrode layers direct laser ablation with structure sizes down to the micrometer range and high aspect ratios were found most powerful in order to create three-dimensional (3D) cell architectures with benefits regarding cell performance and a homogenous wetting of composite electrodes with liquid electrolyte. A huge impact of laser formed 3D batteries regarding capacity retention and cell lifetime at high charging and discharging rates was detected. The impact on diffusion kinetics of laser structured 3D electrodes was studied using classical methods such galvanostatic intermittent titration technique and cyclic voltammetry. A further improvement of 3D battery performance due to an operation in high potential regime and for advanced high energy silicon anode material was achieved by joining of laser structuring and thin-film passivation either of active particles before laser patterning or by passivating of complete 3D electrodes after laser processing. Finally, laser-induced breakdown spectroscopy will be presented as a powerful tool for elemental map** of entire 2D and 3D electrodes. The impact of 3D architectures on lithium distribution and chemical degradation processes in 2D batteries was investigated and analyzed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Notes

- 1.

C-rate of “1C” or “2C” is defined as complete theoretical lithium charge/discharge in 1 or 1/2 h, respectively.

References

J.B. Goodenough, Y. Kim, Challenges for rechargeable Li batteries. Chem. Mater. 22(3), 587–603 (2010). https://doi.org/10.1021/cm901452z

B. Scrosati, J. Garche, Lithium batteries: status, prospects and future. J. Power Sources 195(9), 2419–2430 (2010). https://doi.org/10.1016/j.jpowsour.2009.11.048

G. Amatucci, A. Du Pasquier, A. Blyr, T. Zheng, J.M. Tarascon, The elevated temperature performance of the LiMn2O4/C system: failure and solutions. Electrochim. Acta 45(1–2), 255–271 (1999). https://doi.org/10.1016/S0013-4686(99)00209-1

A. Sakti, Quantification of performance and cost trajectory of Li-ion battery designs for personal vehicle electrification in the near future. Dissertation, Carnegie Mellon University (2013)

D. Andre, S.-J. Kim, P. Lamp, S.F. Lux, F. Maglia, O. Paschos, B. Stiaszny, Future generations of cathode materials: an automotive industry perspective. J. Mater. Chem. A 3(13), 6709–6732 (2015). https://doi.org/10.1039/c5ta00361j

J.W. Long, B. Dunn, D.R. Rolison, H.S. White, Three-dimensional battery architectures. Chem. Rev. 104(10), 4463–4492 (2004)

J.F.M. Oudenhoven, L. Baggetto, P.H.L. Notten, All-solid-state lithium-ion microbatteries: a review of various three-dimensional concepts. Adv. Energy Mater. 1(1), 10–33 (2011). https://doi.org/10.1002/aenm.201000002

R. Kohler, H. Besser, M. Hagen, J. Ye, C. Ziebert, S. Ulrich, J. Pröll, W. Pfleging, Laser micro-structuring of magnetron-sputtered SnOx thin films as anode material for lithium ion batteries. Microsyst. Technol. 17(2), 225–232 (2011). https://doi.org/10.1007/s00542-011-1259-1

H. **a, Y.H. Wan, W. Assenmacher, W. Mader, G.L. Yuan, L. Lu, Facile synthesis of chain-like LiCoO2 nanowire arrays as three-dimensional cathode for microbatteries. NPG Asia Mater. 6 (2014). https://doi.org/10.1038/am.2014.72

W. **ong, Q.Y. **a, H. **a, Three-dimensional self-supported metal oxides as cathodes for microbatteries. Funct. Mater. Lett. 7(5) (2014). https://doi.org/10.1142/S1793604714300035

S. Ferrari, M. Loveridge, S.D. Beattie, M. Jahn, R.J. Dashwood, R. Bhagat, Latest advances in the manufacturing of 3D rechargeable lithium microbatteries. J. Power Sources 286, 25–46 (2015). https://doi.org/10.1016/j.jpowsour.2015.03.133

W. Pfleging, J. Pröll, A new approach for rapid electrolyte wetting in tape cast electrodes for lithium-ion batteries. J. Mater. Chem. A 2(36), 14918–14926 (2014). https://doi.org/10.1039/c4ta02353f

D.G. Lim, D.W. Chung, R. Kohler, J. Pröll, C. Scherr, W. Pfleging, R.E. Garcia, Designing 3D conical-shaped lithium-ion microelectrodes. J. Electrochem. Soc. 161(3), A302–A307 (2014). https://doi.org/10.1149/2.013403jes

J.H. Pikul, H.G. Zhang, J. Cho, P.V. Braun, W.P. King: High-power lithium ion microbatteries from interdigitated three-dimensional bicontinuous nanoporous electrodes. Nat. Commun. 4 (2013). https://doi.org/10.1038/Ncomms2747

H.G. Zhang, X.D. Yu, P.V. Braun, Three-dimensional bicontinuous ultrafast-charge and -discharge bulk battery electrodes. Nat. Nanotechnol. 6(5), 277–281 (2011). https://doi.org/10.1038/Nnano.2011.38

L. Baggetto, R.A.H. Niessen, F. Roozeboom, P.H.L. Notten, High energy density all-solid-state batteries: a challenging concept towards 3D integration. Adv. Funct. Mater. 18(7), 1057–1066 (2008). https://doi.org/10.1002/adfm.200701245

J. **e, J.F.M. Oudenhoven, D.J. Li, C.G. Chen, R.A. Eichel, P.H.L. Notten, High power and high capacity 3D-structured TiO2 electrodes for lithium-ion microbatteries. J. Electrochem. Soc. 163(10), A2385–A2389 (2016). https://doi.org/10.1149/2.1141610jes

J. Pröll, H. Kim, A. Piqué, H.J. Seifert, W. Pfleging, Laser-printing and femtosecond-laser structuring of LiMn2O4 composite cathodes for Li-ion microbatteries. J. Power Sources 255, 116–124 (2014). https://doi.org/10.1016/j.jpowsour.2013.12.132

S. Rosenberg, A. Hintennach, Laser-printed lithium-sulphur micro-electrodes for Li/S batteries. Russ. J. Electrochem. 50(4), 327–335 (2014). https://doi.org/10.1134/S1023193514040065

E. Mottay, X.B. Liu, H.B. Zhang, E. Mazur, R. Sanatinia, W. Pfleging, Industrial applications of ultrafast laser processing. MRS Bull. 41(12), 984–992 (2016). https://doi.org/10.1557/mrs.2016.275

M. Luetke, V. Franke, A. Techel, T. Himmer, U. Klotzbach, A. Wetzig, E. Beyer, A comparative study on cutting electrodes for batteries with lasers. Phys. Proc. 12, 286–291 (2011). https://doi.org/10.1016/j.phpro.2011.03.135

B. Schmieder, Laser cutting of graphite anodes for automotive lithium-ion secondary batteries: investigations in the edge geometry and heat affected zone. Proc. SPIE 8244, 0R1–0R7 (2012)

A.G. Demir, B. Previtali, Remote cutting of Li-ion battery electrodes with infrared and green ns-pulsed fibre lasers. Int. J. Adv. Manufact. Technol. 75(9), 1557–1568 (2014). https://doi.org/10.1007/s00170-014-6231-7

A.H.A. Lutey, A. Fortunato, S. Carmignato, A. Ascari, E. Liverani, G. Guerrini, Quality and productivity considerations for laser cutting of LiFePO4 and LiNiMnCoO2 battery electrodes. Proc. CIRP 42, 433–438 (2016). https://doi.org/10.1016/j.procir.2016.02.227

J. Kurfer, M. Westermeier, C. Tammer, G. Reinhart, Production of large-area lithium-ion cells—preconditioning, cell stacking and quality assurance. CIRP Ann. Manufact. Technol. 61(1), 1–4 (2012). https://doi.org/10.1016/j.cirp.2012.03.101

R. Kohler, J. Pröll, M. Bruns, S. Ulrich, H.J. Seifert, W. Pfleging, Conical surface structures on model thin-film electrodes and tape-cast electrode materials for lithium-ion batteries. Appl. Phys. A 112(1), 77–85 (2013). https://doi.org/10.1007/s00339-012-7205-y

H. Kim, J. Pröll, R. Kohler, W. Pfleging, A. Pique, Laser-printed and processed LiCoO2 cathodethick films for LI-ion microbatteries. J. Laser Micro Nanoeng. 7(3), 320–325 (2012). https://doi.org/10.2961/jlmn.2012.03.0016

J.S. Kim, W. Pfleging, R. Kohler, H.J. Seifert, T.Y. Kim, D. Byun, H.G. Jung, W.C. Choi, J.K. Lee, Three-dimensional silicon/carbon core-shell electrode as an anode material for lithium-ion batteries. J. Power Sources 279, 13–20 (2015). https://doi.org/10.1016/j.jpowsour.2014.12.041

X.-X. Tang, W. Liu, B.-Y. Ye, Y. Tang, Preparation of current collector with blind holes and enhanced cycle performance of silicon-based anode. Trans. Nonferrous Met. Soc. China 23(6), 1723–1727 (2013). https://doi.org/10.1016/S1003-6326(13)62654-0

P.H.L. Notten, F. Roozeboom, R.A.H. Niessen, L. Baggetto, 3-D integrated all-solid-state rechargeable batteries. Adv. Mater. 19(24), 4564–4567 (2007)

R. Kohler, P. Smyrek, S. Ulrich, M. Bruns, V. Trouillet, W. Pfleging, Patterning and annealing of nanocrystalline LiCoO2 thin films. J. Optoelectron. Adv. Mater. 12(3), 547–552 (2010)

J. Pröll, R. Kohler, M. Torge, S. Ulrich, C. Ziebert, M. Bruns, H.J. Seifert, W. Pfleging, Laser microstructuring and annealing processes for lithium manganese oxide cathodes. Appl. Surf. Sci. 257, 9968–9976 (2011)

J. Pröll, P.G. Weidler, R. Kohler, A. Mangang, S. Heissler, H.J. Seifert, W. Pfleging, Comparative studies of laser annealing technique and furnace annealing by X-ray diffraction and Raman analysis of lithium manganese oxide thin films for lithium-ion batteries. Thin Solid Films 531, 160–171 (2013). https://doi.org/10.1016/j.tsf.2013.01.015

K.-Y. Oh, J.B. Siegel, L. Secondo, S.U. Kim, N.A. Samad, J. Qin, D. Anderson, K. Garikipati, A. Knobloch, B.I. Epureanu, C.W. Monroe, A. Stefanopoulou, Rate dependence of swelling in lithium-ion cells. J. Power Sources 267, 197–202 (2014). https://doi.org/10.1016/j.jpowsour.2014.05.039

X. Su, Q.L. Wu, J.C. Li, X.C. **ao, A. Lott, W.Q. Lu, B.W. Sheldon, J. Wu, Silicon-based nanomaterials for Lithium-ion batteries: a review. Adv. Energy Mater. 4(1) (2014). https://doi.org/10.1002/Aenm.201300882

D. Chen, S. Indris, M. Schulz, B. Gamer, R. Mönig, In situ scanning electron microscopy on lithium-ion battery electrodes using an ionic liquid. J. Power Sources 196(15), 6382–6387 (2011). https://doi.org/10.1016/j.jpowsour.2011.04.009

T. Yoon, C.C. Nguyen, D.M. Seo, B.L. Lucht, Capacity fading mechanisms of silicon nanoparticle negative electrodes for lithium ion batteries. J. Electrochem. Soc. 162(12), A2325–A2330 (2015). https://doi.org/10.1149/2.0731512jes

H. Wu, Y. Cui, Designing nanostructured Si anodes for high energy lithium ion batteries. Nano Today 7(5), 414–429 (2012). https://doi.org/10.1016/j.nantod.2012.08.004

A. Magasinski, B. Zdyrko, I. Kovalenko, B. Hertzberg, R. Burtovyy, C.F. Huebner, T.F. Fuller, I. Luzinov, G. Yushin, Toward efficient binders for Li-ion battery si-based anodes: polyacrylic acid. ACS Appl. Mater. Interfaces 2(11), 3004–3010 (2010). https://doi.org/10.1021/am100871y

C. Erk, T. Brezesinski, H. Sommer, R. Schneider, J. Janek, Toward silicon anodes for next-generation lithium ion batteries: a comparative performance study of various polymer binders and silicon nanopowders. ACS Appl. Mater. Interfaces 5(15), 7299–7307 (2013). https://doi.org/10.1021/am401642c

Y. Zheng, Z. An, P. Smyrek, H.J. Seifert, T. Kunze, V. Lang, A.F. Lasagni, W. Pfleging, Direct laser interference patterning and ultrafast laser-induced micro/nano structuring of current collectors for lithium-ion batteries. Proc. SPIE 9736, 1B1–1B7 (2016)

A.F. Lasagni, C. Gachot, K.E. Trinh, M. Hans, A. Rosenkranz, T. Roch, S. Eckhardt, T. Kunze, M. Bieda, D. Günther, V. Lang, F. Mücklich, Direct laser interference patterning, 20 years of development: from the basics to industrial applications. Proc. SPIE 10092, 11 (2017)

J.H. Klein-Wiele, P. Simon, Fabrication of periodic nanostructures by phase-controlled multiple-beam interference. Appl. Phys. Lett. 83(23), 4707–4709 (2003). https://doi.org/10.1063/1.1631746

W. Pfleging, R. Kohler, M. Torge, V. Trouillet, F. Danneil, M. Stüber, Control of wettability of hydrogenated amorphous carbon thin films by laser-assisted micro- and nanostructuring. Appl. Surf. Sci. 257(18), 7907–7912 (2011). https://doi.org/10.1016/j.apsusc.2011.02.126

A.Y. Vorobyev, C. Guo, Direct femtosecond laser surface nano/microstructuring and its applications. Laser Photonics Rev. 7(3), 385–407 (2013). https://doi.org/10.1002/lpor.201200017

J. Bonse, S. Höhm, S.V. Kirner, A. Rosenfeld, J. Krüger, Laser-induced periodic surface structures—a scientific evergreen. IEEE J. Sel. Top. Quantum Electron. 23(3), 1–15 (2017). https://doi.org/10.1109/jstqe.2016.2614183

J. Bonse, A. Rosenfeld, J. Krüger, On the role of surface plasmon polaritons in the formation of laser-induced periodic surface structures upon irradiation of silicon by femtosecond-laser pulses. J. Appl. Phys. 106(10), 104910 (2009). https://doi.org/10.1063/1.3261734

V.S. Makin, R.S. Makin, A.Y. Vorobyev, C. Guo, Dissipative nanostructures and Feigenbaum’s universality in the “metal-high-power ultrashort-pulsed polarized radiation” nonequilibrium nonlinear dynamical system. Tech. Phys. Lett. 34(5), 387–390 (2008). https://doi.org/10.1134/s1063785008050088

Y. Zheng, Z. An, P. Smyrek, H.J. Seifert, T. Kunze, V. Lang, A.F. Lasagni, W. Pfleging, Laser interference patterning and laser-induced periodic surface structure formation on metallic substrates, in 2016 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO) (2016), pp. 159–163. https://doi.org/10.1109/3m-nano.2016.7824955

N. Zhang, Y. Zheng, A. Trifonova, W. Pfleging, Laser structured Cu foil for high-performance lithium-ion battery anodes. J. Appl. Electrochem., 1–9 (2017). https://doi.org/10.1007/s10800-017-1086-x

W. Pfleging, P. Gotcu, Femtosecond laser processing of thick film cathodes and its impact on lithium-ion diffusion kinetics. Appl. Sci. 9(17), 3588 (2019)

J. Pröll, R. Kohler, A. Mangang, S. Ulrich, C. Ziebert, W. Pfleging, 3D structures in battery materials. J. Laser Micro Nanoeng. 7(1), 97–104 (2012). https://doi.org/10.2961/jlmn.2012.01.0019

P. Gotcu, H.J. Seifert, Thermophysical properties of LiCoO2–LiMn2O4 blended electrode materials for Li-ion batteries. Phys. Chem. Chem. Phys. 18(15), 10550–10562 (2016). https://doi.org/10.1039/c6cp00887a

A. Manthiram, T. Muraliganth, Lithium intercalation cathode materials for lithium-ion batteries, in Handbook of Battery Material. ed. by C. Daniel, J.O. Besenhar (Wiley-VCH Verlag GmbH & Co., Weinheim, 2011), pp. 343–375

P. Smyrek, J. Pröll, H.J. Seifert, W. Pfleging, Laser-induced breakdown spectroscopy of laser-structured Li(NiMnCo)O2 electrodes for lithium-ion batteries. J. Electrochem. Soc. 163(2), A19–A26 (2016). https://doi.org/10.1149/2.0981514jes

P. Gotcu, W. Pfleging, P. Smyrek, H.J. Seifert, Thermal behaviour of LixMeO2 (Me = Co or Ni + Mn + Co) cathode materials. Phys. Chem. Chem. Phys. 19, 11920–11930 (2017). https://doi.org/10.1039/c7cp00513j

W. Weppner, R.A. Huggins, Determination of the kinetic parameters of mixed-conducting electrodes and application to the system Li3Sb. J. Electrochem. Soc. 124(10), 1569–1578 (1977). https://doi.org/10.1149/1.2133112

J.N. Reimers, J.R. Dahn, Electrochemical and in situ X-ray-diffraction studies of lithium intercalation in LixCoO2. J. Electrochem. Soc. 139(8), 2091–2097 (1992). https://doi.org/10.1149/1.2221184

Z.H. Chen, J.R. Dahn, Methods to obtain excellent capacity retention in LiCoO2 cycled to 4.5 V. Electrochim. Acta 49(7), 1079–1090 (2004). https://doi.org/10.1016/j.electacta.2003.10.019

Y. Reynier, J. Graetz, T. Swan-Wood, P. Rez, R. Yazami, B. Fultz, Entropy of Li intercalation in LixCoO2. Phys. Rev. B 70(17), 174304 (2004)

J.N. Reimers, J.R. Dahn, U. Vonsacken, Effects of impurities on the electrochemical properties of LiCoO2. J. Electrochem. Soc. 140(10), 2752–2754 (1993). https://doi.org/10.1149/1.2220905

K. Chang, B. Hallstedt, D. Music, J. Fischer, C. Ziebert, S. Ulrich, H.J. Seifert, Thermodynamic description of the layered O3 and O2 structural LiCoO2–CoO2 pseudo-binary systems. Calphad 41, 6–15 (2013). https://doi.org/10.1016/j.calphad.2013.01.001

G. Denuault, M. Sosna, K.-J. Williams, 11—classical experiments A2—Zoski, Cynthia G, in Handbook of Electrochemistry (Elsevier, Amsterdam, 2007), pp. 431–469

J.S. Hong, J.R. Selman, Relationship between calorimetric and structural characteristics of lithium-ion cells—II. Determination of Li transport properties. J. Electrochem. Soc. 147(9), 3190–3194 (2000). https://doi.org/10.1149/1.1393882

M. Mangang, P. Gotcu-Freis, H.J. Seifert, W. Pfleging, Electrochemical and kinetic studies of ultrafast laser structured LiFePO4 electrodes. Proc. SPIE 9351, 0K1–0K12 (2015). https://doi.org/10.1117/12.2078900

K. Tang, X. Yu, J. Sun, H. Li, X. Huang, Kinetic analysis on LiFePO4 thin films by CV, GITT, and EIS. Electrochim. Acta 56(13), 4869–4875 (2011). https://doi.org/10.1016/j.electacta.2011.02.119

T. Teranishi, Y. Yoshikawa, R. Sakuma, H. Hashimoto, H. Hayashi, A. Kishimoto, T. Fujii, High-rate performance of ferroelectric BaTiO3-coated LiCoO2 for Li-ion batteries. Appl. Phys. Lett. 105(14), 143904-1–143904-3 (2014). https://doi.org/10.1063/1.4898006

Q. Hao, C.X. Xu, S.Z. Jia, X.Y. Zhao, Improving the cycling stability of LiCoO2 at 4.5 V through surface modification by Fe2O3 coating. Electrochim. Acta 113, 439–445 (2013). https://doi.org/10.1016/j.electacta.2013.09.105

Q. Hao, H.Y. Ma, Z.C. Ju, G.D. Li, X.W. Li, L.Q. Xu, Y.T. Qian, Nano-CuO coated LiCoO2: synthesis, improved cycling stability and good performance at high rates. Electrochim. Acta 56(25), 9027–9031 (2011). https://doi.org/10.1016/j.electacta.2011.04.097

Y. Bai, K. Jiang, S.W. Sun, Q. Wu, X. Lu, N. Wan, Performance improvement of LiCoO2 by MgF2 surface modification and mechanism exploration. Electrochim. Acta 134, 347–354 (2014). https://doi.org/10.1016/j.electacta.2014.04.155

H.M. Cheng, F.M. Wang, J.P. Chu, R. Santhanam, J. Rick, S.C. Lo, Enhanced cycleabity in lithium ion batteries: resulting from atomic layer depostion of Al2O3 or TiO2 on LiCoO2 electrodes. J. Phys. Chem. C 116(14), 7629–7637 (2012). https://doi.org/10.1021/jp210551r

E. Jung, Y.J. Park, Characterization of thermally aged AlPO4-coated LiCoO2 thin films. Nanoscale Res. Lett. 7, 1–4 (2012). https://doi.org/10.1186/1556-276x-7-12

C. Hudaya, J.H. Park, J.K. Lee, W. Choi, SnO2-coated LiCoO2 cathode material for high-voltage applications in lithium-ion batteries. Solid State Ionics 256, 89–92 (2014). https://doi.org/10.1016/j.ssi.2014.01.016

B.J. Hwang, C.Y. Chen, M.Y. Cheng, R. Santhanam, K. Ragavendran, Mechanism study of enhanced electrochemical performance of ZrO2-coated LiCoO2 in high voltage region. J. Power Sources 195(13), 4255–4265 (2010). https://doi.org/10.1016/j.jpowsour.2010.01.040

X.Y. Dai, L.P. Wang, J. Xu, Y. Wang, A.J. Zhou, J.Z. Li, Improved electrochemical performance of LiCoO2 electrodes with ZnO coating by radio frequency magnetron sputtering. ACS Appl. Mater. Interfaces 6(18), 15853–15859 (2014). https://doi.org/10.1021/am503260s

Y. Orikasa, D. Takamatsu, K. Yamamoto, Y. Koyama, S. Mori, T. Masese, T. Mori, T. Minato, H. Tanida, T. Uruga, Z. Ogumi, Y. Uchimoto, Origin of surface coating effect for MgO on LiCoO2 to improve the interfacial reaction between electrode and electrolyte. Adv. Mater. Interfaces 1(9) (2014). https://doi.org/10.1002/Admi.201400195

Q. Cao, H.P. Zhang, G.J. Wang, Q. **a, Y.P. Wu, H.Q. Wu, A novel carbon-coated LiCoO2 as cathode material for lithium ion battery. Electrochem. Commun. 9(5), 1228–1232 (2007). https://doi.org/10.1016/j.elecom.2007.01.017

J. Kim, B. Kim, J.G. Lee, J. Cho, B. Park, Direct carbon-black coating on LiCoO2 cathode using surfactant for high-density Li-ion cell. J. Power Sources 139(1–2), 289–294 (2005). https://doi.org/10.1016/j.jpowsour.2004.07.008

J.H. Park, C. Hudaya, A.Y. Kim, D.K. Rhee, S.J. Yeo, W. Choi, P.J. Yoo, J.K. Lee, Al-C hybrid nanoclustered anodes for lithium ion batteries with high electrical capacity and cyclic stability. Chem. Commun. 50(22), 2837–2840 (2014). https://doi.org/10.1039/c3cc47900e

C. Hudaya, B. Kang, H.G. Jung, W. Choi, B.J. Jeon, J.K. Lee, Plasma-polymerized C-60 as a functionalized coating layer on fluorine-doped tin oxides for anode materials of lithium-ion batteries. Carbon 81, 835–838 (2015). https://doi.org/10.1016/j.carbon.2014.09.015

A.A. Arie, J.K. Lee, Fullerene C-60 coated silicon nanowires as anode materials for lithium secondary batteries. J. Nanosci. Nanotechnol. 12(4), 3547–3551 (2012). https://doi.org/10.1166/jnn.2012.5557

A.A. Arie, O.M. Vovk, J.K. Lee, Surface-coated silicon anodes with amorphous carbon film prepared by fullerene C-60 sputtering. J. Electrochem. Soc. 157(6), A660–A665 (2010). https://doi.org/10.1149/1.3363531

C. Hudaya, M. Halim, J. Proll, H. Besser, W. Choi, W. Pfleging, H.J. Seifert, J.K. Lee, A polymerized C60 coating enhancing interfacial stability at three-dimensional LiCoO2 in high-potential regime. J. Power Sources 298, 1–7 (2015). https://doi.org/10.1016/j.jpowsour.2015.08.044

A.A. Arie, J.O. Song, J.K. Lee, Structural and electrochemical properties of fullerene-coated silicon thin film as anode materials for lithium secondary batteries. Mater. Chem. Phys. 113(1), 249–254 (2009). https://doi.org/10.1016/j.matchemphys.2008.07.082

J. Mun, T. Yim, J.H. Park, J.H., Ryu, S.Y. Lee, Y.G. Kim, S.M. Oh, Allylic ionic liquid electrolyte-assisted electrochemical surface passivation of LiCoO2 for advanced, safe lithium-ion batteries. Sci. Rep. 4 (2014). https://doi.org/10.1038/Srep05802

J.P. Yu, Z.H. Han, X.H. Hu, H. Zhan, Y.H. Zhou, X.J. Liu, The investigation of Ti-modified LiCoO2 materials for lithium ion battery. J. Power Sources 262, 136–139 (2014). https://doi.org/10.1016/j.jpowsour.2014.03.073

H. Castaneda, The impedance response of different mechanisms for LiCoO2/acetylene carbon electrodes in alkaline solutions under polarization conditions. Electrochim. Acta 112, 562–576 (2013). https://doi.org/10.1016/j.electacta.2013.08.177

F. Boue-Bigne, Laser-induced breakdown spectroscopy applications in the steel industry: rapid analysis of segregation and decarburization. Spectrochim. Acta Part B Atom. Spectrosc. 63(10), 1122–1129 (2008). https://doi.org/10.1016/j.sab.2008.08.014

J.M. Vadillo, J.J. Laserna, Laser-induced plasma spectrometry: truly a surface analytical tool. Spectrochim. Acta Part B Atom. Spectrosc. 59(2), 147–161 (2004). https://doi.org/10.1016/j.sab.2003.11.006

J.M. Vadillo, C.C. Garcia, S. Palanco, J.J. Laserna, Nanometric range depth-resolved analysis of coated-steels using laser-induced breakdown spectrometry with a 308 nm collimated beam. J. Anal. At. Spectrom. 13(8), 793–797 (1998). https://doi.org/10.1039/A802343c

V. Zorba, J. Syzdek, X.L. Mao, R.E. Russo, R. Kostecki, Ultrafast laser induced breakdown spectroscopy of electrode/electrolyte interfaces. Appl. Phys. Lett. 100(23) (2012). https://doi.org/10.1063/1.4724203

H.M. Hou, L. Cheng, T. Richardson, G.Y. Chen, M. Doeff, R. Zheng, R. Russo, V. Zorba, Three-dimensional elemental imaging of Li-ion solid-state electrolytes using FS-laser induced breakdown spectroscopy (LIBS). J. Anal. At. Spectrom. 30(11), 2295–2302 (2015). https://doi.org/10.1039/c5ja00250h

P. Smyrek, Y. Zheng, J.H. Rakebrandt, H.J. Seifert, W. Pfleging, Investigation of micro-structured Li(Ni1/3Mn1/3Co1/3)O2 cathodes by laser-induced breakdown spectroscopy. Proc. SPIE 10092, 0S1–0S7 (2017). https://doi.org/10.1117/12.2253894

P. Smyrek, Y. Zheng, H.J. Seifert, W. Pfleging, Post-mortem characterization of FS laser-generated micro-pillars in Li(Ni1/3Mn1/3Co1/3)O2 electrodes by laser-induced breakdown spectroscopy. Proc. SPIE 9736, 1C1–1C6 (2016)

P. Smyrek, Y. Zheng, H.J. Seifert, W. Pfleging, Laser-induced breakdown spectroscopy as a powerful tool for characterization of laser modified composite materials, in 2016 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO), 18–22 July 2016, pp. 164–167

H.H. Zheng, G. Liu, X.Y. Song, P. Ridgway, S.D. Xun, V.S. Battaglia, Cathode performance as a function of inactive material and void fractions. J. Electrochem. Soc. 157(10), A1060–A1066 (2010). https://doi.org/10.1149/1.3459878

P. Smyrek, T. Bergfeldt, H.J. Seifert, W. Pfleging, Laser-induced breakdown spectroscopy for the quantitative measurement of lithium concentration profiles in structured and unstructured electrodes. J. Mater. Chem. A 7(10), 5656–5665 (2019). https://doi.org/10.1039/c8ta10328c

S.L. Wu, W. Zhang, X. Song, A.K. Shukla, G. Liu, V. Battaglia, V. Srinivasan, High rate capability of Li(Ni1/3Mn1/3Co1/3)O2 electrode for Li-ion batteries. J. Electrochem. Soc. 159(4), A438–A444 (2012). https://doi.org/10.1149/2.062204jes

Acknowledgements

We thank the financial support by the German Federal Ministry of Education and Research (BMBF) in frame of the Korea-Germany Mobility Programme (01DR14018). Furthermore, this work was supported by KIST institutional program and research grants of NRF (NRF-2012M1A2A2671792) funded by the National Research Foundation under the Ministry of Science, ICT & Future, Korea. The work on laser processing and 3D battery has received funding from the German Research Foundation (DFG, Project No. 392322200). The authors thank to Dr. Melanie Mangang, Dr. Robert Kohler, Dr. Johannes Pröll, Dr. Jung Sub Kim, and Prof. Dr. Chairul Hudaya for their scientific and technical contributions of many years to the 3D battery concept.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Pfleging, W., Gotcu, P., Smyrek, P., Zheng, Y., Lee, J.K., Seifert, H.J. (2020). Lithium-Ion Battery—3D Micro-/Nano-Structuring, Modification and Characterization. In: Hu, A. (eds) Laser Micro-Nano-Manufacturing and 3D Microprinting. Springer Series in Materials Science, vol 309. Springer, Cham. https://doi.org/10.1007/978-3-030-59313-1_11

Download citation

DOI: https://doi.org/10.1007/978-3-030-59313-1_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-59312-4

Online ISBN: 978-3-030-59313-1

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)