Abstract

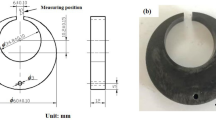

The strength, ductility, and cutting performance can be seriously affected by the size and distribution of inclusions in the steel . Using a high-temperature tube electric resistance furnace, the effect of Mg addition on the evolution of inclusions in 16MnCrS5 steel was investigated. Besides, the deformation behavior of inclusions was carried out by a simulated testing rolling mill (Gleeble-3500). The results showed that the ratio of compound inclusions (MgO ·Al2O3 wrapped by MnS) increased after Mg addition in steel , and the same trend was obtained in the aspect ratio of inclusion together with the ability of resisting the deformation of inclusions after hot-extruding. With the increasing of Mg addition from 8 ppm to 42 ppm, the mean area of inclusions in experimental ingots first decreased and then increased. Additionally, the peak mean area of inclusions occurred under the Mg content of 35 ppm.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Wang YN, Bao YP, Wang M, Zhang LC (2013) Smelting process and machinability of BN-type free cutting steel. J Univ Sci Technol Bei**g 35(7):869

Liu Y, Zhang L, Zhang Y, Duan HJ, Ren Y, Yang W (2018) Effect of sulfur in steel on transient evolution of inclusions during calcium treatment. Metall Mater Trans B 49(2):610–626

Wang YN, Yang J, Bao YP (2015) Effects of non-metallic inclusions on machinability of free-cutting steels investigated by nano-indentation measurements. Metall Mater Trans A 46(1):281–292

Shi CB, Yu WT, Wang H, Li J, Jiang M (2017) Simultaneous modification of alumina and MgO·Al2O3 inclusions by calcium treatment during electroslag remelting of stainless tool steel. Metall Mater Trans B 48(1):146–161

Geldenhuis JMA, Pistorius PC (2000) Minimisation of calcium additions to low carbon steel grades. Ironmak Steelmak 27(6):442–449

Mainy D (1996) Morphological and analytical characterization of inclusions: Relation with processing parameters and properties of use. Mater Charact 36(4–5):321–326

Maciejewski J (2015) The Effects of Sulfide Inclusions on mechanical properties and failures of steel components. J Fail Anal Prev 15(2):169–178

Li L, Zhu R, Sun Y, Guo H, Yin H, Dong J (2004) Form and distribution of inclusions and Tin in free-cutting steel. J Univ Sci Technol Bei**g 26(5):471–473

Xu J, Yang QK, Cheng J et al (2017) The evolution and thermodynamic analysis of inclusions in gear steel after magnesium treatment. In: Paper presented at international conference on manufacturing engineering and intelligent materials, Guangzhou, China, 25–26 February 2017

Chiang YM, Kingery WD (1989) Grain-boundary migration in nonstoichiometric solid solutions of magnesium aluminate spinel: i, grain growth studies. J Am Ceram Soc 72(2):271–277

Zhang TS, Wang DY, Jiang MF (2014) Effect of magnesium on evolution of oxide and sulphide in liquid iron at 1873K. J Iron Steel Res Int 21(12):1073–1080

Jiang L, Cui K (1997) Quantitative study of modification of sulphide inclusions by calcium and its effect on the impact toughness of a resulfurised alloy steel. Steel Res 68(4):163–168

Acknowledgements

This work is sponsored by the National Natural Science Foundation of China (51874195 and 51671124).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Liu, H., **e, Y., Yang, Q., Zhou, Q., Ma, J. (2020). Modification of Inclusions by Adding Mg to 16MnCrS5 Gear Steel. In: Peng, Z., et al. 11th International Symposium on High-Temperature Metallurgical Processing. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-36540-0_53

Download citation

DOI: https://doi.org/10.1007/978-3-030-36540-0_53

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-36539-4

Online ISBN: 978-3-030-36540-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)