Abstract

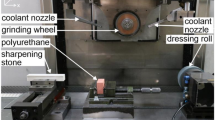

High depth of cut grinding has attracted special interest as a means of increasing productivity. The surface plunge grinding at high depths of cut to 150 um has been performed for soft and hardened die steels. Through the experiment, the wheel wear rate, the actual metal removal rate, and grinding ratio were determined for increasing metal removal rate, using various wheels of different wheel grade, grain size, and grain type. Also, grinding fluid effect was investigated. In special, the characterization of wheel wear was made in detail,and.discussed in related to grain fracture or bond fracture.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

S. Ohmori, T. Egawa and T. Yamada: Study on the Jet Infusion Grinding Method, Paper presented at 1977 AES Int. Conf., May (1977).

R.N. Stauffer: Getting More Work from the Grinding Process, Manuf. Eng., June(1977) p.68.

G. Lutz and H. Noichl: Tiefschleifen, Werkstatt and Betrieb, 111, 7 (1978) p. 427.

H.J. Dilling, et al: Schleifen als Abtragintensive Bearbeitung, Werkstatt and Betrieb, 111, 7 (1978) p. 417.

H. Opitz: High efficiency grinding, Proc. of Seminar on European Development in Horizons in Manuf. Tech., April(1967) p.84.

B. Colding, et al: Recent Research and Development in Grinding, Annals of CIRP, 21 (1972) p. 157.

T. Matsuo: The effect of high depth of cut on grinding performance of alloy steels, Proc. 14 th MTDR Conf., 14(1974) p.633.

T. Matsuo and Sectional Committee of Heavy Grinding of Steels (JSPE): Abrasive Machining of Alloy Steels by Conventional Grinding Machines, Proc. Int. Conf. Prod. Eng., Tokyo (1974) p.659.

Yasui, T. Matsuo and E. Oshima: On the Wear Characteristic of Grinding Wheel in High Depth of Cut Dry Grinding, J. Jap. Soc. Prec. Eng., 42, 11 (1976) p. 1027.

H. Nakazono, H. Yasui and A. Sunamoto: Studies on Quantitative Analysis of Radial Wheel Wear in Heavy Grinding, J. Jap. Soc. Prec. Eng., 42,9 (1976) p. 163.

H. Yasui and T. Matsuo: On the Wear Characteristic of Grinding Wheel in High Depth of Cut Wet Grinding (Part 2), J. Jap. Soc. Prec. Eng., 45, 1 (1979) p. 62.

J. Peklenik and H. Opitz: Testing of Grinding Wheels, Advances in Machine Tool Design and Research, (1962) p. 163.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Copyright information

© 1980 The Department of Mechanical Engineering, University of Birmingham

About this chapter

Cite this chapter

Yasui, H., Matsuo, T. (1980). Characterization of Wheel Wear in High Depth of Cut Grinding. In: Tobias, S.A. (eds) Proceedings of the Twentieth International Machine Tool Design and Research Conference. Palgrave Macmillan, London. https://doi.org/10.1007/978-1-349-05172-4_45

Download citation

DOI: https://doi.org/10.1007/978-1-349-05172-4_45

Publisher Name: Palgrave Macmillan, London

Print ISBN: 978-1-349-05174-8

Online ISBN: 978-1-349-05172-4

eBook Packages: Springer Book Archive