Abstract

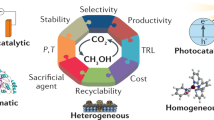

Carbon dioxide (CO2) has been increasingly regarded not only as a greenhouse gas but also as a valuable feedstock for carbon-based chemicals. In particular, biological approaches have drawn attention as models for the production of value-added products, as CO2 conversion serves many natural processes. Enzymatic CO2 reduction in vitro is a very promising route to produce fossil free and bio-based fuel alternatives, such as methanol. In this chapter, the advances in constructing competitive multi-enzymatic systems for the reduction of CO2 to methanol are discussed. Different integrated methods are presented, aiming to address technological challenges, such as the cost effectiveness, need for material regeneration and reuse and improving product yields of the process.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kober T, Schiffer HW, Densing M, Panos E (2020) Global energy perspectives to 2060 – WEC’s World Energy Scenarios 2019. Energy Strategy Rev. 31(December 2019):100523. https://doi.org/10.1016/j.esr.2020.100523

Letcher TM (2021) Global warming—a complex situation. Clim Chang:3–17. https://doi.org/10.1016/b978-0-12-821575-3.00001-3

Hiloidhari M, Baruah DC, Kumari M, Kumari S, Thakur IS (2019) Prospect and potential of biomass power to mitigate climate change: a case study in India. J Clean Prod 220:931–944. https://doi.org/10.1016/j.jclepro.2019.02.194

Schiffer ZJ, Manthiram K (2017) Electrification and decarbonization of the chemical industry. Joule 1(1):10–14. https://doi.org/10.1016/j.joule.2017.07.008

Zhang Z et al (2020) Advances in carbon capture, utilization and storage. Appl Energy 278:115627. https://doi.org/10.1016/j.apenergy.2020.115627

Bond GM, Stringer J, Brandvold DK, Simsek FA, Medina MG, Egeland G (2000) Development of integrated system for biomimetic CO2 sequestration using the enzyme carbonic anhydrase. ACS Div Fuel Chem Prepr 45(4):713–717

Sivanesan D et al (2017) Enhanced CO2 absorption and desorption in a tertiary amine medium with a carbonic anhydrase mimic. J Ind Eng Chem 52:287–294. https://doi.org/10.1016/j.jiec.2017.03.058

Sjöblom M et al (2020) Enzyme-assisted CO2 absorption in aqueous amino acid ionic liquid amine blends. ACS Sustain Chem Eng 8(36):13672–13682. https://doi.org/10.1021/acssuschemeng.0c03497

Shin W, Lee SH, Shin JW, Lee SP, Kim Y (2003) Highly selective electrocatalytic conversion of CO2 to CO at −0.57 V (NHE) by carbon monoxide dehydrogenase from moorella thermoacetica. J Am Chem Soc 125(48):14688–14689. https://doi.org/10.1021/ja037370i

Woolerton TW, Sheard S, Reisner E, Pierce E, Ragsdale SW, Armstrong FA (2010) Efficient and clean photoreduction of CO2 to CO by enzyme-modified TiO2 nanoparticles using visible light. J Am Chem Soc 132(7):2132–2133. https://doi.org/10.1021/ja910091z

Yu S et al (2020) Light-driven enzymatic nanosystem for highly selective production of formic acid from CO2. Chem Eng J (August):127649. https://doi.org/10.1016/j.cej.2020.127649

Gu FJ, Wang YZ, Meng ZH, Liu WF, Qiu LY (2020) A coupled photocatalytic/enzymatic system for sustainable conversion of CO2 to formate. Catal Commun 136(December 2019):105903. https://doi.org/10.1016/j.catcom.2019.105903

Ren S et al (2020) Co-immobilization multienzyme nanoreactor with co-factor regeneration for conversion of CO2. Int J Biol Macromol 155:110–118. https://doi.org/10.1016/j.ijbiomac.2020.03.177

Li Y, Wen L, Tan T, Lv Y (2019) Sequential co-immobilization of enzymes in metal-organic frameworks for efficient biocatalytic conversion of adsorbed CO2 to formate. Front Bioeng Biotechnol 7(December):1–13. https://doi.org/10.3389/fbioe.2019.00394

Shi J, Wang X, Jiang Z, Liang Y, Zhu Y, Zhang C (2012) Constructing spatially separated multienzyme system through bioadhesion-assisted bio-inspired mineralization for efficient carbon dioxide conversion. Bioresour Technol 118:359–366. https://doi.org/10.1016/j.biortech.2012.04.099

Liu W, Hou Y, Hou B, Zhao Z (2014) Enzyme-catalyzed sequential reduction of carbon dioxide to formaldehyde. Chin J Chem Eng 22(11):1328–1332. https://doi.org/10.1016/j.cjche.2014.09.026

Nabavi Zadeh PS, Gomes MZDV, Åkerman B, Palmqvist AEC (2018) Förster resonance energy transfer study of the improved biocatalytic conversion of CO2 to formaldehyde by coimmobilization of enzymes in siliceous mesostructured cellular foams. ACS Catal 8(8):7251–7260. https://doi.org/10.1021/acscatal.8b01806

Yang ZY, Moure VR, Dean DR, Seefeldt LC (2012) Carbon dioxide reduction to methane and coupling with acetylene to form propylene catalyzed by remodeled nitrogenase. Proc Natl Acad Sci U S A 109(48):19644–19648. https://doi.org/10.1073/pnas.1213159109

Sultana S, Chandra Sahoo P, Martha S, Parida K (2016) A review of harvesting clean fuels from enzymatic CO2 reduction. RSC Adv 6(50):44170–44194. https://doi.org/10.1039/c6ra05472b

Dalena F, Senatore A, Marino A, Gordano A, Basile M, Basile A (2018) Methanol production and applications: an overview. Elsevier B.V., Amsterdam

Zhang N, Long R, Gao C, **ong Y (2018) Recent progress on advanced design for photoelectrochemical reduction of CO2 to fuels. Sci China Mater 61(6):771–805. https://doi.org/10.1007/s40843-017-9151-y

Maia LB, Moura I, Moura JJG (2017) Molybdenum and tungsten-containing formate dehydrogenases: aiming to inspire a catalyst for carbon dioxide utilization. Inorganica Chim Acta 455:350–363. https://doi.org/10.1016/j.ica.2016.07.010

Fauque GD, Barton LL (2012) Hemoproteins in dissimilatory sulfate- and sulfur-reducing prokaryotes, vol 60, 1st edn. Elsevier, Amsterdam

Choe H et al (2014) Efficient CO2-reducing activity of NAD-dependent formate dehydrogenase from Thiobacillus sp. KNK65MA for formate production from CO 2 gas. PLoS One 9(7):14–16. https://doi.org/10.1371/journal.pone.0103111

Nielsen CF, Lange L, Meyer AS (2019) Classification and enzyme kinetics of formate dehydrogenases for biomanufacturing via CO2 utilization. Biotechnol Adv 37(7):107408. https://doi.org/10.1016/j.biotechadv.2019.06.007

Schütte H, Flossdorf J, Sahm H, Kula M-R (1976) Purification and properties of formaldehyde dehydrogenase and formate dehydrogenase from candida boidinii. Eur J Biochem 62(1):151–160. https://doi.org/10.1111/j.1432-1033.1976.tb10108.x

Schirwitz K, Schmidt A, Lamzin VS (2007) High-resolution structures of formate dehydrogenase from Candida boidinii. Protein Sci 16(6):1146–1156. https://doi.org/10.1110/ps.062741707

Guo Q et al (2016) Structural and kinetic studies of formate dehydrogenase from Candida boidinii. Biochemistry 55(19):2760–2771. https://doi.org/10.1021/acs.biochem.6b00181

Harris C, Wang SW, Lauchu JJ, Hansen JM (2003) Methanol metabolism and embryotoxicity in rat and mouse conceptuses: comparisons of alcohol dehydrogenase (ADH1), formaldehyde dehydrogenase (ADH3), and catalase. Reprod Toxicol 17(3):349–357. https://doi.org/10.1016/S0890-6238(03)00013-3

Yang ZN, Bosron WF, Hurley TD (1997) Structure of human χχ alcohol dehydrogenase: a glutathione-dependent formaldehyde dehydrogenase. J Mol Biol 265(3):330–343. https://doi.org/10.1006/jmbi.1996.0731

Pourmotabbed T, Creighton DJ (1986) Substrate specificity of bovine liver formaldehyde dehydrogenase. J Biol Chem 261(30):14240–14244. https://doi.org/10.1016/s0021-9258(18)67010-3

Marx CJ, Miller JA, Chistoserdova L, Lidstrom ME (2004) Multiple formaldehyde oxidation/detoxification pathways in burkholderia fungorum LB400. J Bacteriol 186(7):2173–2178. https://doi.org/10.1128/JB.186.7.2173-2178.2004

Gutheil WG, Kasimoglu E, Nicholson PC (1997) Induction of glutathione-dependent formaldehyde dehydrogenase activity in Escherichia coli and Hemophilus influenza. Biochem Biophys Res Commun 238(3):693–696. https://doi.org/10.1016/S0006-291X(00)90000-7

Kato N, Sahm H, Wagner F (1979) Steady-state kinetics of formaldehyde dehydrogenase and formate dehydrogenase from a methanol-utilizing yeast, Candida boidinii. BBA Enzymol 566(1):12–20. https://doi.org/10.1016/0005-2744(79)90243-2

Thompson CM, Ceder R, Grafström RC (2010) Formaldehyde dehydrogenase: beyond phase I metabolism. Toxicol Lett 193(1):1–3. https://doi.org/10.1016/j.toxlet.2009.11.023

Ando M, Yoshtmoto T, Ogushl S, Rikitake K, Shibata S, Tsuru D (1979) Formaldehyde dehydrogenase from Pseudomonas putida: purification and some properties. J Biochem 85(5):1165–1172. https://doi.org/10.1093/oxfordjournals.jbchem.a132440

Tanaka N, Kusakabe Y, Ito K, Yoshimoto T, Nakamura KT (2002) Crystal structure of formaldehyde dehydrogenase from Pseudomonas putida: the structural origin of the tightly bound cofactor in nicotinoprotein dehydrogenases. J Mol Biol 324(3):519–533. https://doi.org/10.1016/S0022-2836(02)01066-5

Persson B, Hedlund J, Jörnvall H (2008) Medium- and short-chain dehydrogenase/reductase gene and protein families: the MDR superfamily. Cell Mol Life Sci 65(24):3879–3894. https://doi.org/10.1007/s00018-008-8587-z

Hurley TD, Edenberg H (2012) Gene encoding enzymes in alcohol metabolism. Alcohol Res Curr Rev 34(3):339–344. [Online]. Available: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3756590/pdf/arcr-34-3-339.pdf

Vallee BL, Hoch FL (1955) Zinc, A component of yeast alcohol dehydrogenase. Proceedings of the National Academy of Sciences 41(6):327–338

Wills C (1976) Production of yeast alcohol dehydrogenase isoenzymes by selection. Nature 261(5555):26–29. https://doi.org/10.1038/261026a0

Leskovac V, Trivić S, Peričin D (2002) The three zinc-containing alcohol dehydrogenases from baker’s yeast, Saccharomyces cerevisiae. FEMS Yeast Res 2(4):481–494. https://doi.org/10.1016/S1567-1356(02)00157-5

Raj SB, Ramaswamy S, Plapp BV (2014) Yeast alcohol dehydrogenase structure and catalysis. Biochemistry 53(36):5791–5803. https://doi.org/10.1021/bi5006442

Zdarta J, Meyer AS, Jesionowski T, Pinelo M (2018) A general overview of support materials for enzyme immobilization: characteristics, properties, practical utility. Catalysts 8(2). https://doi.org/10.3390/catal8020092

Obert R, Dave BC (1999) Enzymatic conversion of carbon dioxide to methanol: enhanced methanol production in silica sol-gel matrices [5]. J Am Chem Soc 121(51):12192–12193. https://doi.org/10.1021/ja991899r

Xu SW, Lu Y, Li J, Jiang ZY, Wu H (2006) Efficient conversion of CO2 to methanol catalyzed by three dehydrogenases co-encapsulated in an alginate-silica (ALG-SiO2) hybrid gel. Ind Eng Chem Res 45(13):4567–4573. https://doi.org/10.1021/ie051407l

Sun Q, Jiang Y, Jiang Z, Zhang L, Sun X, Li J (2009) Green and efficient conversion of CO2 to methanol by biomimetic coimmobilization of three dehydrogenases in protamine-templated titania. Ind Eng Chem Res 48(9):4210–4215. https://doi.org/10.1021/ie801931j

Wang X et al (2014) Bioinspired approach to multienzyme cascade system construction for efficient carbon dioxide reduction. ACS Catal 4(3):962–972. https://doi.org/10.1021/cs401096c

Jiang Y, Sun Q, Zhang L, Jiang Z (2009) Capsules-in-bead scaffold: a rational architecture for spatially separated multienzyme cascade system. J Mater Chem 19(47):9068–9074. https://doi.org/10.1039/b914268a

Luo J, Meyer AS, Mateiu RV, Pinelo M (2015) Cascade catalysis in membranes with enzyme immobilization for multi-enzymatic conversion of CO2 to methanol. New Biotechnol 32(3):319–327. https://doi.org/10.1016/j.nbt.2015.02.006

Ji X, Su Z, Ma G, Zhang S (2018) Sandwiching multiple dehydrogenases and shared cofactor between double polyelectrolytes for enhanced communication of cofactor and enzymes. Biochem Eng J 137:40–49. https://doi.org/10.1016/j.bej.2018.05.017

El-Zahab B, Donnelly D, Wang P (2008) Particle-tethered NADH for production of methanol from CO2 catalyzed by coimmobilized enzymes. Biotechnol Bioeng 99(3):508–514. https://doi.org/10.1002/bit.21584

Ji X, Su Z, Wang P, Ma G, Zhang S (2015) Tethering of nicotinamide adenine dinucleotide inside hollow nanofibers for high-yield synthesis of methanol from carbon dioxide catalyzed by coencapsulated multienzymes. ACS Nano 9(4):4600–4610. https://doi.org/10.1021/acsnano.5b01278

Marques Netto CGC, Andrade LH, Toma HE (2018) Carbon dioxide/methanol conversion cycle based on cascade enzymatic reactions supported on superparamagnetic nanoparticles. An Acad Bras Cienc 90(1):593–606. https://doi.org/10.1590/0001-3765201720170330

Zhu D et al (2019) Ordered coimmobilization of a multienzyme cascade system with a metal organic framework in a membrane: reduction of CO2 to methanol. ACS Appl Mater Interfaces 11(37):33581–33588. https://doi.org/10.1021/acsami.9b09811

Cazelles R, Drone J, Fajula F, Ersen O, Moldovan S, Galarneau A (2013) Reduction of CO2 to methanol by a polyenzymatic system encapsulated in phospholipids-silica nanocapsules. New J Chem 37(11):3721–3730. https://doi.org/10.1039/c3nj00688c

Singh RK et al (2018) Insights into cell-free conversion of CO2 to chemicals by a multienzyme cascade reaction. ACS Catal 8(12):11085–11093. https://doi.org/10.1021/acscatal.8b02646

Zhang Z et al (2018) Efficient ionic liquid-based platform for multi-enzymatic conversion of carbon dioxide to methanol. Green Chem 20(18):4339–4348. https://doi.org/10.1039/c8gc02230e

Lee SH, Choi DS, Kuk SK, Park CB (2018) Photobiocatalysis: activating redox enzymes by direct or indirect transfer of photoinduced electrons. Angew Chem Int Ed. 57(27):7958–7985. https://doi.org/10.1002/anie.201710070

Dibenedetto A et al (2012) Hybrid technologies for an enhanced carbon recycling based on the enzymatic reduction of CO2 to methanol in water: chemical and photochemical NADH regeneration. ChemSusChem 5(2):373–378. https://doi.org/10.1002/cssc.201100484

Aresta M, Dibenedetto A, Baran T, Angelini A, Łabuz P, Macyk W (2014) An integrated photocatalytic/enzymatic system for the reduction of CO2 to methanol in bioglycerol-water. Beilstein J Org Chem 10:2556–2565. https://doi.org/10.3762/bjoc.10.267

Yadav RK, Oh GH, Park NJ, Kumar A, Kong KJ, Baeg JO (2014) Highly selective solar-driven methanol from CO2 by a photocatalyst/biocatalyst integrated system. J Am Chem Soc 136(48):16728–16731. https://doi.org/10.1021/ja509650r

Liu J, Cazelles R, Chen ZP, Zhou H, Galarneau A, Antonietti M (2014) The bioinspired construction of an ordered carbon nitride array for photocatalytic mediated enzymatic reduction. Phys Chem Chem Phys 16(28):14699–14705. https://doi.org/10.1039/c4cp01348d

Ji X, Su Z, Wang P, Ma G, Zhang S (2016) Integration of artificial photosynthesis system for enhanced electronic energy-transfer efficacy: a case study for solar-energy driven bioconversion of carbon dioxide to methanol. Small 12(34):4753–4762. https://doi.org/10.1002/smll.201600707

Wu R, Ma C, Zhu Z (2020) Enzymatic electrosynthesis as an emerging electrochemical synthesis platform. Curr Opin Electrochem 19:1–7. https://doi.org/10.1016/j.coelec.2019.08.004

Spinner NS, Vega JA, Mustain WE (2012) Recent progress in the electrochemical conversion and utilization of CO 2. Cat Sci Technol 2(1):19–28. https://doi.org/10.1039/c1cy00314c

Schlager S et al (2017) Biocatalytic and bioelectrocatalytic approaches for the reduction of carbon dioxide using enzymes. Energy Technol 5(6):812–821. https://doi.org/10.1002/ente.201600610

Schlager S, Fuchsbauer A, Haberbauer M, Neugebauer H, Sariciftci NS (2017) Carbon dioxide conversion to synthetic fuels using biocatalytic electrodes. J Mater Chem A 5(6):2429–2443. https://doi.org/10.1039/c6ta07571a

Kuwabata S, Tsuda R, Yoneyama H (1994) Electrochemical conversion of carbon dioxide to methanol with the assistance of formate dehydrogenase and methanol dehydrogenase as biocatalysts. J Am Chem Soc 116(12):5437–5443. https://doi.org/10.1021/ja00091a056

Addo PK, Arechederra RL, Waheed A, Shoemaker JD, Sly WS, Minteer SD (2011) Methanol production via bioelectrocatalytic reduction of carbon dioxide: role of carbonic anhydrase in improving electrode performance. Electrochem Solid-State Lett 14(4):5–10. https://doi.org/10.1149/1.3537463

Zhang Z et al (2021) Encapsulation of multiple enzymes in a metal-organic framework with enhanced electro-enzymatic reduction of CO2 to methanol. Green Chem 23(6):2362–2371. https://doi.org/10.1039/d1gc00241d

Schlager S et al (2016) Electrochemical reduction of carbon dioxide to methanol by direct injection of electrons into immobilized enzymes on a modified electrode. ChemSusChem 9(6):631–635. https://doi.org/10.1002/cssc.201501496

Barton Cole E, Lakkaraju PS, Rampulla DM, Morris AJ, Abelev E, Bocarsly AB (2010) Using a one-electron shuttle for the multielectron reduction of CO2 to methanol: kinetic, mechanistic, and structural insights. J Am Chem Soc 132(33):11539–11551. https://doi.org/10.1021/ja1023496

Kuk SK, Singh RK, Nam DH, Singh R, Lee JK, Park CB (2017) Photoelectrochemical reduction of carbon dioxide to methanol through a highly efficient enzyme cascade. Angew Chem Int Ed 56(14):3827–3832. https://doi.org/10.1002/anie.201611379

Windle CD, Perutz RN (2012) Advances in molecular photocatalytic and electrocatalytic CO 2 reduction. Coord Chem Rev 256(21–22):2562–2570. https://doi.org/10.1016/j.ccr.2012.03.010

Marpani F, Pinelo M, Meyer AS (2017) Enzymatic conversion of CO2 to CH3OH via reverse dehydrogenase cascade biocatalysis: quantitative comparison of efficiencies of immobilized enzyme systems. Biochem Eng J 127:217–228. https://doi.org/10.1016/j.bej.2017.08.011

Effendi SSW, Ng IS (2019) The prospective and potential of carbonic anhydrase for carbon dioxide sequestration: a critical review. Process Biochem. 87(July):55–65. https://doi.org/10.1016/j.procbio.2019.08.018

Kanth BK, Lee J, Pack SP (2013) Carbonic anhydrase: its biocatalytic mechanisms and functional properties for efficient CO2 capture process development. Eng Life Sci 13(5):422–431. https://doi.org/10.1002/elsc.201200157

Russo ME, Olivieri G, Marzocchella A, Salatino P, Caramuscio P, Cavaleiro C (2013) Post-combustion carbon capture mediated by carbonic anhydrase. Sep Purif Technol 107:331–339. https://doi.org/10.1016/j.seppur.2012.06.022

Kupriyanova E, Pronina N, Los D (2017) Carbonic anhydrase — a universal enzyme of the carbon-based life. Photosynthetica 55(1):3–19. https://doi.org/10.1007/s11099-017-0685-4

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Science+Business Media, LLC, part of Springer Nature

About this protocol

Cite this protocol

Antonopoulou, I., Rova, U., Christakopoulos, P. (2022). CO2 to Methanol: A Highly Efficient Enzyme Cascade. In: Stamatis, H. (eds) Multienzymatic Assemblies. Methods in Molecular Biology, vol 2487. Humana, New York, NY. https://doi.org/10.1007/978-1-0716-2269-8_19

Download citation

DOI: https://doi.org/10.1007/978-1-0716-2269-8_19

Published:

Publisher Name: Humana, New York, NY

Print ISBN: 978-1-0716-2268-1

Online ISBN: 978-1-0716-2269-8

eBook Packages: Springer Protocols