Abstract—

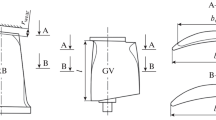

To determine the rational parameters of the wet cleaning process of the gas turbine engine flow path, it is proposed to conduct tests (instead of expensive pilot tests of engines) on a small size analogous test bench installation. This test bench was created according to the method developed on the basis of a generalized model of friction and wear. Based on the consideration of physical processes during the movement of an air-liquid flow through the flow path of the engine, a multifactorial mathematical model of the hydrogas erosion of the pollution film, i.e., its wear (destruction) during the movement of a dispersed system of liquid medium particles in the air–gas flow of a working engine, is substantiated and constructed. This made it possible, based on the provisions of the generalized model of friction and wear, to express the main characteristic of the process, intensity of wear Ih (destruction) of the film of contamination through the engine parameters known from the permit data. In order to comply with geometrically identical conditions, wet cleaning on an analogous test bench is proposed to be carried out on a cassette of real (full-scale) samples in the form of a sector of blades taken from the compressor guide block. To test the advanced provisions of the methodology, an experimental test bench was designed and manufactured. It was intended for testing the parameters of the wet cleaning modes of the flow part of the NK-12ST ground-based gas turbine engine. According to the results of experimental tests, the dependences of the cleaning time on the pressure of the regime’s air on the temperature of the purifier liquid and on its supply pressure to the flow part were obtained.

Similar content being viewed by others

REFERENCES

Andriets, A.G., Pavlov, S.V., and Korotich, A.A., The use of a solid cleaner for cleaning operating GTE, Gazoturbinnye Tekhnol., 2005, no. 5, pp. 32–34.

Porshakov, B.P., et al., Povyshenie effektivnosti ekspluatatsii energoprivoda kompressornykh stantsii: proizvodstvenno-prakticheskoe izdanie (Improving the Operational Efficiency of the Power Drive of Compressor Stations: Manufacturing and Practical Edition), Moscow: Nedra, 1992.

Gogolev, I.G., Drokonov, A.M., and Nikolaev, A.D., Influence of deposits in the flow path on the performance of turbomachines, Vestn. Bryansk. Gos. Tekh. Univ., 2006, no. 4, pp. 22–28.

Jeffs, E., Compressor washing on line for large gas turbine, Turbomach. Int., 1992, vol. 33, no. 6, pp. 49–51.

Stalder, J.P., Gas turbine compressor washing state of the art—field experiences, Proc. ASME 1998 Int. Gas Turbine and Aeroengine Congr. and Exhibition, New York: ASME Int., 1998, no. 1998-GT-420.

Silaev, B.M. and Mal’tsev, E.N., Generalized mehtods of calculation and design of a wet cleaning system for a GTE flow path, Vestn. Samar. Gos. Aerokosm. Univ., 2011, no. 3-3 (27), pp. 277–281.

Silaev, B.M., Thermodynamic principles of generalized model of the friction and wear process, Trenie Iznos, 2017, vol. 38, no. 6, pp. 546–555.

Kulagin, V.V., Teoriya, raschet i proektirovanie aviatsionnykh dvigatelei i energeticheskikh ustanovok. Kniga 1. Osnovy teorii GTD. Rabochii protsess i termogazodinamicheskii analiz (Theory, Calculation, and Design of Aircraft Engines and Power Devices, Book 1: Fundamentals of the Theory of Gas Turbine Engines. Workflow and Thermogasdynamic Analysis), Moscow: Mashinostroenie, 2003.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Silaev, B.M., Dolgikh, D.E. Determination of the Parameters of the Process of Wet Cleaning of the Flow Path of Gas Turbine Engines Based on a Generalized Model of Friction and Wear. J. Frict. Wear 42, 447–453 (2021). https://doi.org/10.3103/S106836662106012X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106836662106012X