Abstract

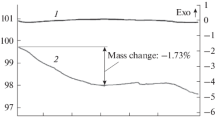

The powder metallurgy method, including the mechanical activation of powders in a planetary mill and spark plasma sintering at 1470°C in an inert atmosphere, is used to obtain NiAl–45 vol % Al2O3 cermet samples with the addition of nanoparticles of magnesium aluminum spinel in an amount of 0.05 vol %. The features of their microstructure are investigated. Spinel nanoparticles are located at the boundaries between the grains of the composite components. The results of X-ray diffraction analysis at t = 25 and 800°C are obtained. The main components of the material at t = 20°C are α-Al2O3 and NiAl. The dependence of internal friction on the temperature in the range of 20–900°C is studied, and the influence of magnesium aluminum spinel nanoparticles on the nature of its change is established. The internal friction curve shows that vibration dam** occurs up to 600°C. Dependences of the bending strength of cermets at t = 20–750°C are determined. The positive effect of the introduction of a small amount of magnesium aluminum spinel on the elastic properties of composites is established. The best mechanical properties are demonstrated for NiAl–42 vol % Al2O3–0.05 vol % MgAl2O4 samples. On average, the ultimate bending strength of this material is 8–15% higher compared to samples without nanoparticles. The materials obtained in this research had a bending strength under normal conditions of 460–490 MPa. A summarizing analysis of NiAl–Al2O3 cermet research is carried out to determine the nature of the dependence of the bending strength on the ratio of components. It is found that it has an extreme nature: the maximum is observed when using the ratio of aluminum oxide to aluminum nickel equal to 0.5.

Similar content being viewed by others

REFERENCES

Kamei, T., Recent research of thorium molten-salt reactor from a sustainability viewpoint, Sustainability, 2012, vol. 4, pp. 2399–2418. https://doi.org/10.3390/su4102399

Abou-Jaoude, A., Palmer, J., Sterbentz, J., and Calderoni, P., Evaluation of a Versatile Experimental Salt Irradiation Loop (VESIL) Inside the Advanced Test Reactor, Report NL/EXT-19-52917-2019, Idaho National Laboratory, 2019. https://doi.org/10.2172/1511048

Agureev, L.E., Kostikov, V.I., Eremeeva, Zh.V., Barmin, A.A., Rizakhanov, R.N., Ivanov, B.S., Ashmarin, A.A., Laptev, I.I., and Rudshtein, R.I., Powder aluminum composites of Al–Cu system with micro-additions of oxide nanoparticles, Inorg. Mater. Appl. Res., 2016, vol. 7, no. 6, pp. 507–510. https://doi.org/10.1134/s2075113316050026

Lurie, S., Volkov-Bogorodskiy, D., Solyaev, Yu., Rizahanov, R., and Agureev, L., Multiscale modeling of aluminium-based metal-matrix composites with oxide nanoinclusions, Comput. Mater. Sci., 2016, vol. 116, pp. 62–73. https://doi.org/10.1016/j.commatsci.2015.12.034

Yang, C., Muransky, O., Zhu, H., Thorogood, G.J., Avdeev, M., Huang, H., and Zhou, X., The effect of milling time on the microstructural characteristics and strengthening mechanisms NiMo-SiC alloys prepared via powder metallurgy, Mater. Des., 2017, vol. 113, pp. 223–231. https://doi.org/10.3390/ma10040389

Joo, H., Han, Ch., Kim, B., Kim, D., and Choi, H., Interface activated sintering of tungsten by nano-particles in the spark plasma sintering, J. Adv. Mater. Sci., 2011, vol. 28, pp. 200–206.

Chuvildeev, V.N., Nerevnovesnye granitsy zeren v metallakh. Teoriya i prilozheniya (Non-Equilibrium Grain Boundaries in Metals. Theory and Applications), Moscow: Fizmatlit, 2004.

Weeks, R.A. and Sonder, E., Electrical conductivity of pure and Fe-doped magnesium-aluminum spinel, J. Am. Ceram. Soc., 1980, vol. 63, nos. 1–2, pp. 92–95. https://doi.org/10.1111/j.1151-2916.1980.tb10656.x

Peters, D.W., Feinstein, L., and Peltzer, C., On the high-temperature electrical conductivity of alumina, J. Chem. Phys., 1965, vol. 42, no. 7, pp. 2345–2346. https://doi.org/10.1063/1.1696298

Munir, Z.A., Tamburini, U.A., and Ohyanagi, M., The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method, J. Mater. Sci., 2006, vol. 41, pp. 763–777. https://doi.org/10.1007/s10853-006-6555-2

Shen, Z., Johnsson, M., Zhao, Z., and Nygren, M., Formation of tough interlocking microstructures in silicon nitride ceramics by dynamic ripening, Nature, 2002, vol. 417, pp. 266–269. https://doi.org/10.1038/417266a

Olevsky, E. and Froyen, L., Constitutive modeling of spark-plasma sintering of conductive materials, Scr. Mater., 2006, vol. 55, pp. 1175–1178. https://doi.org/10.1016/j.scriptamat.2006.07.009

Li, C., Habler, G., Griffiths, T., Rečnik, A., Jeřábek, P., Götze, L.C., Mangler, C., Pennycook, T.J., Meyer, J., and Abart, R., Structure evolution of h.c.p./c.c.p. metal oxide interfaces in solid-state reactions, Acta Crystallogr., Sect. A: Found. Adv., 2018, vol. 74, pp. 466–480. https://doi.org/10.1107/S205327331800757X

Hwang, C.-S., Liu, T.-J., Shich, J.-P., Tuan, W.-H., and Guo, J.-K., Metal oxidation process: NiAl/Al2O3 composites, in Multiphased Ceramic Materials—Processing and Potential, Tuan, W.-H. and Guo, J.-K., Eds., Berlin, Heidelberg: Springer, 2004, pp. 87–97.

Kalinski, D., Chmielewski, M., Pietrzak, K., and Choregiewicz, K., An influence of mechanical mixing and hot-pressing on properties of NiAl/Al2O3 composite, Arch. Metall. Mater., 2012, vol. 57, no. 3, pp. 695–702. https://doi.org/10.2478/v10172-012-0075-7

Chang, S.T., Tuan, W.H., You, H.C., and Lin, I.C., Effect of surface grinding on the strength of NiAl and Al2O3/NiAl composites, Mater. Chem. Phys., 1999, vol. 59, pp. 220–224. https://doi.org/10.1016/S0254-0584(99)00060-7

Chmielewski, M., Nosewicz, S., Pietrzak, K., Rojek, J., Strojny-Nędza, A., Mackiewicz, S., and Dutkiewicz, J., Sintering behavior and mechanical properties of NiAl, Al2O3, and NiAl–Al2O3 composites, J. Mater. Eng. Perform., 2014, vol. 23, pp. 3875–3886. https://doi.org/10.1007/s11665-014-1189-z

Agureev, L.E., Kostikov, V.I., Laptev, I.N., Kanushkin, A.I., Eremeeva, Zh.V., Ivanov, A.V., Ashmarin, A.A., Vysotina, E.A., and Ivanov, B.S., Preparation and study of Ni–Al–O system cermet composites with a small addition of MgAl2O4 nanoparticles, Russ. J. Non-Ferrous Met., 2020, vol. 61, no. 3, pp. 375–381. https://doi.org/10.3103/S1067821220030025

Kaliński, D., Chmielewski, M., and Pietrzak, K., Mechanical, thermal and tribological properties of hot-pressed NiAl/Al2O3 composites, Proc. 15th European Conference on Composite Materials, Venice, 2012. http://www.escm.eu.org/eccm15/data/assets/580.pdf.

Davies, I.J., Pezzotti, G., Bellosi, A., Sciti, D., and Guicciardi, S., Mechanical behavior of nickel aluminide reinforced alumina (Al2O3–NiAl) composites, Adv. Compos. Lett., 2002, vol. 11, no. 6, pp. 265–273. https://doi.org/10.1177/096369350201100601

Upadhyay, A., Beniwal, R.S., and Singh, R., Elastic properties of Al2O3–NiAl: A modified version of Hashin-Shtrikman bounds, Continuum Mech. Thermodyn., 2012, vol. 24, pp. 257–266. https://doi.org/10.1007/s00161-012-0237-x

Hsieh, C.L., Tuan, W.H., and Wu, T.T., Elastic behavior of a model two phase material, J. Eur. Ceram. Soc., 2004, vol. 24, pp. 3789–3793. https://doi.org/10.1016/j.jeurceramsoc.2004.02.002

Qi, G., Shangguan, F., Yang, L., Bai, Q., and Wu, G., Microstructure and mechanical properties of Al2O3/NiAl in situ composites by hot-press-aided reaction synthesis, Adv. Mater. Res., 2012, vols. 581–582, pp. 548–551. https://doi.org/10.4028/www.scientific.net/AMR.581-582.548

Lenel, F.V. and Ansell, G.S., A Theory of Dispersion Strengthening, Springfield, VA: National Technical Information Service, U.S. Department of Commerce, 1960. https://ntrs.nasa.gov/citations/19620002956.

Nosewicz, S., Rojek, J., Mackiewicz, S., Chmielewski, M., Pietrzak, K., and Romelczyk, B., The influence of hot pressing conditions on mechanical properties of nickel aluminide/alumina composite, J. Compos. Mater., 2014, vol. 48, pp. 3577–3589. https://doi.org/10.1177/0021998313511652

Weller, M., Hirscher, M., Schweizer, E., and Kronrniiller, H., High temperature internal friction in NiAl single crystals, J. Phys. IV, 1996, vol. 6, pp. 231–234. https://doi.org/10.1051/jp4:1996849

Hirscher, M., Hirscher, E., Schweizer, M., Weller, H., and Kronmüller, H., Internal friction in NiAl single crystals, Philos. Mag. Lett., 1996, vol. 74, no. 3, pp. 189–194.

Hirscher, M. and Schaible, D., Internal friction in plastically deformed high-purity NiAl single crystals, MRS Proc., 1998, vol. 552, pp. KK8.2.2–KK8.2.6. https://doi.org/10.1557/PROC-552-KK8.2.1

Hirth, J.P. and Lothe, J., Theory of Dislocations, New York: Wiley, 1982.

Dezerald, L., Proville, L., Ventelon, L., Willaime, F., and Rodne, D., First-principles prediction of kink-pair activation enthalpy on screw dislocations in bcc transition metals: V, Nb, Ta, Mo, W, and Fe, Phys. Rev. B, 2015, vol. 91, pp. 94–105. https://doi.org/10.1103/PhysRevB.91.094105

Proville, L., Ventelon, L., and Rodney, D., Prediction of the kink-pair formation enthalpy on screw dislocations in α-iron by a line tension model parametrized on empirical potentials and first-principles calculations, Phys. Rev. B, 2013, vol. 87, p. 144106.

Shved, O.V., Mudry, S.I., and Kulyk, Yu.O., High-temperature X-ray diffraction studies of Al–Ni–Hf ternary alloys, Phys. Chem. Solid State, 2017, vol. 18, no. 3, pp. 324–327. https://doi.org/10.15330/pcss.18.3.324-327

Blanter, M.S., Golovin, I.S., Neuhäuser, H., and Sinning, H.-R., Internal Friction in Metallic Materials, Berlin: Springer, 2007. https://doi.org/10.1007/978-3-540-68758-0

Wu, J., Han, F.S., Wang, Q.Z., Hao, G.L., and Gao, Z.Y., The internal friction peaks correlated to the relaxation of atomic defects in Fe47Al53 alloy, Intermetallics, 2007, vol. 15, pp. 838–844. https://doi.org/10.1016/j.intermet.2006.10.037

Nguyen, K.N. and Dang, K.C., Synthesis, characterization and catalytic activity of CoAl2O4 and NiAl2O4 spinel-type oxides for NOx selective reduction, Adv. Technol. Mater. Mater. Process. J., 2004, vol. 6, no. 2, pp. 336–343. https://doi.org/10.2240/azojomo0129

Sheludyak, Yu.E., Kashporov, L.Ya., Malinin, L.A., and Tsalkov, V.N., Teplofizicheskie svoistva komponentov goryuchikh smesei (Thermophysical Properties of Components of Combustible Systems), Moscow: NPO Inform TEI, 1992.

Kalita, P., Ghosh, S., Singh, U.B., Kulriya, P.K., Grover, V., Shukla, R., Tyagi, A.K., Sattonnay, G., and Avasthi, D.K., Enhanced Radiation Tolerance of YSZ at High Temperature Against Swift Heavy Ions: Key Role of Interplay Between Material Microstructure and Irradiation Temperature. https://arxiv.org/abs/1806.10024.

Wen, J., Sun, C., Dholabhai, P., **a, Y., Tang, M., Chen, D., Yang, D., Li, Y., Uberuaga, B.P., and Wang, Y., Temperature dependence of the radiation tolerance of nanocrystalline pyrochlores A2Ti2O7 (A = Gd, Ho and Lu), Acta Mater., 2016, vol. 110, pp. 175–184. https://doi.org/10.1016/j.actamat.2016.03.025

El-Atwani, O., Esquivel, E., Efe, M., Aydogan, E., Wang, Y., Martinez, E., and Maloy, S., Loop and void damage during heavy ion irradiation on nanocrystalline and coarse grained tungsten: Microstructure, effect of dpa rate, temperature, and grain size, Acta Mater., 2018, vol. 149, pp. 206–219. https://doi.org/10.1016/j.actamat.2018.02.035

Jagielskia, J., Piatkowskaa, A., Aubert, P., Labdi, S., Maciejak, O., Romaniec, M., Thomé, L., Jozwik, I., Debelle, A., Wajler, A., and Boniecki, M., Effect of grain size on mechanical properties of irradiated mono- and polycrystalline MgAl2O4, Acta Phys. Pol., A, 2011, vol. 120, no. 1, pp. 118–121. https://doi.org/10.12693/APHYSPOLA.120.118

ACKNOWLEDGMENTS

This research was funded by the Russian Foundation for Basic Research (project no. 19-03-00350 А, “Develo** Methods to Improve Strength and Functional Properties of Nickel-Based Cermet Materials”).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by N. Saetova

About this article

Cite this article

Agureev, L.E., Kostikov, V.I., Eremeeva, Z.V. et al. Study of the Structure and Properties of Cermets Based on the NiAl–Al2O3 System. Russ. J. Non-ferrous Metals 62, 763–770 (2021). https://doi.org/10.3103/S106782122106002X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106782122106002X