Abstract

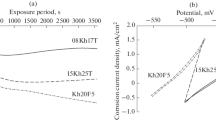

The effect of silicon (in range 0.14–0.78 wt %), boron, and rare-earth metals (REM) on the corrosion resistance of low-carbon austenitic chromium-nickel steel of 03Kh18N11 (AISI 304L) grade was studied. It is shown that all steels in the quenched state when tested in boiling 56 and 65% HNO3 solutions have comparable corrosion rates, which do not exceed the critical norm (0.5 mm/year) in accordance with GOST 6032–2017 (State Standard). Testing samples in boiling 27% HNO3 + 4 g/L Cr+6 solution are susceptible to intergranular corrosion (IGC). The corrosion rate and the penetration depth of IGC increase with additional silicon concentration from 0.14 to 0.78 wt %. The study focused on the effect of nitric acid concentration and test temperature has shown that steel with 0.78 wt % Si has significant corrosion losses exceeding the critical ones when testing in 56 and 65% HNO3 solutions with temperature of 120 and 130°С. But steel with high silicon content (0.78 wt %) and low carbon concentration (0.020–0.022%) after quenching in a range of 1080–1150°C and tempering at 650°C does not exceed the critical norm on average corrosion rate. Only 0.01 wt % increase in carbon concentration leads to a significant (more than 30 times) increase in corrosion rate of sensitized steel. It is shown that microalloying with REM does not impair corrosion resistance of sensitized steel. In contrast to REM, alloying chromium-nickel steel with even a small addition of boron (0.0015%) reduces steel corrosion resistance by an order of magnitude. Corrosion rate inverse dependence on quenching temperature is observed when, with increasing temperature, corrosion rate of 02Kh18N11GS0.38R steel increases.

Similar content being viewed by others

REFERENCES

Naumenko, V.V., Nitrogen and silicon effect on mechanical and corrosion properties of low-carbon austenitic steel for use in highly oxidizing environments, Extended Abstract of Cand. Sci. (Eng.) Dissertation, Moscow, 2012.

Sahlaoui, H., Sidhom, H., and Philibert, J., Prediction of chromium depleted-zone evolution during aging of Ni–Cr–Fe alloys, Acta Mater., 2002, vol. 50, no. 6, pp. 1383–1392.

Laurent, B., Gruet, N., Gwinner, B., Miserque, F., Soares-Teixeira, V., and Ogle, K., Silicon enrichment of an austenitic stainless steel—Impact on electrochemical behavior in concentrated nitric acid with oxidizing ions, Electrochim. Acta, 2019, vol. 322, no. 1, art. ID 134703.

Laurent, B., Gruet, N., Gwinner, B., Miserque, F., Rousseau, K., and Ogle, K., The kinetics of transpassive dissolution chemistry of stainless steels in nitric acid: the impact of Si, Electrochim. Acta, 2017, vol. 258, no. 20, pp. 653–661.

Sourmail, T., Too, C.H., and Bhadeshia, H.K.D.H., Sensitization and evolution of chromium-depleted zones in Fe–Cr–Ni–C systems, ISIJ Int., 2003, vol. 43, no. 11, pp. 1814–1820.

Kain, V. and De, P.K., Controlling corrosion in the back end of fuel cycle using nitric acid grade stainless steels, Int. J. Nucl. Energy Sci. Technol., 2005, vol. 1, nos. 2–3, pp. 220–231.

Robin, R., Miserque, F., and Spagnol, V., Correlation between composition of passive layer and corrosion behavior of high Si-containing austenitic stainless steels in nitric acid, J. Nucl. Mater., 2008, vol. 375, no. 1, pp. 65–71.

Perrin, A.R. and Aust, K.T., Intergranular corrosion of high purity austenitic stainless steel containing silicon additions, Mater. Sci. Eng., 1981, vol. 51, no. 2, pp. 165–174.

Armijo, J.S. and Wilde, B.E., Influence of Si content on the corrosion resistance of austenitic Fe–Cr–Ni alloys in oxidizing acids, Corros. Sci., 1968, vol. 8, no. 9, pp. 649–664.

Wilde, B.E., Influence of Silicon on the intergranular corrosion behavior of 18Cr–8Ni stainless steels, Corros. Sci., 1988, vol. 44, no. 10, pp. 699–704.

Kajimura, H., Usuki, N., and Nagano, H., Dual layer corrosion protective film formed on Si bearing austenitic stainless steel in highly oxidizing nitric acid, Proc. Symp. on Passivity and Its Breakdown, Pennington, NJ: Electrochem. Soc., 1998, pp. 332–343.

Kasparova, O.V., Peculiarities of intergranular corrosion of siliconcontaining austenitic stainless steels, Zashch. Met., 2004, vol. 40, no. 5, pp. 475–481.

Ningshen, S., Mudali, U.K., Amarendra, G., and Ray, B., Corrosion assessment of nitric acid grade austenitic stainless steels, Corros. Sci., 2009, vol. 51, no. 2, pp. 322–329.

Gwinner, B., Auroy, M., Balbaud-Celerier, F., Fauvet, P., Larabi-Gruet, N., Laghoutaris, P., and Robin, R., Towards a reliable determination of he intergranular corrosion rate of austenitic stainless steel in oxidizing media, Corros. Sci., 2016, vol. 107, pp. 60–75.

Ningshen, S., Mudali, U.K., Ramya, S., and Raj, B., Corrosion behavior of AISI type 304L stainless steel in nitric acid media containing oxidizing species, Corros. Sci., 2011, vol. 53, no. 1, pp. 64–70.

Huang, K. and Loge, R.E., Microstructure and flow stress evolution during hot deformation of 304L austenitic stainless steel in variable thermomechanical conditions, Mater. Sci. Eng., A, 2018, vol. 711, pp. 600–610.

Stewart, G.R., Jonas, J.J., and Montheillet, F., Kinetics and critical conditions for the initiation of dynamic recrystallization in 304 stainless steel, ISIJ Int., 2004, vol. 44, no. 9, pp. 1581–1589.

Mukherjee, M. and Pal, T.K., Role of microstructural constituents on surface crack formation during hot rolling of standard and low nickel austenitic stainless steels, Acta Metall. Sin., 2013, vol. 26, no. 2, pp. 206–216.

Nkhoma, R.K.C., Siyasiya, C.W., and Stumpf, W.E., Hot workability of AISI 321 and AISI 304 austenitic stainless steels, J. Alloys Compd., 2014, vol. 595, pp. 103–112.

Blinov, V.M., Structure and properties of high-temperature austenitic steels for superheater tubes, Russ. Metall. (Engl. Transl.), 2009, vol. 2009, no. 6, pp. 478–487.

Chen, L., Zhang, Y., Li, F., Liu, X., Guo, B., and **, M., Modeling of dynamic recrystallization behavior of 21Cr–11Ni–N–RE lean austenitic heat-resistant steel during hot deformation, Mater. Sci. Eng., A, 2016, vol. 663, pp. 141–150.

Solntsev, Yu.P., Ermakov, B.S., and Malikov, S.O., Role of silicon in the formation of the corrosion resistance of austenitic materials for cryogenic engineering, Russ. Metall. (Engl. Transl.), 2008, vol. 2008, no. 2, pp. 133–137.

Fauvet, P., Balbaud, F., Robin, R., Tran, Q.-T., Mugnier, A., and Espinoux, D., Corrosion mechanisms of austenitic stainless steels in nitric media used in reprocessing plants, J. Nucl. Mater., 2008, vol. 375, no. 1, pp. 52–64.

Kasparova, O.V., Milman, V.M., and Kostromina, S.V., Mechanism of silicon effect on intergranular corrosion of tempered austenitic stainless steels, Zashch. Met., 1991, vol. 27, no. 1, pp. 55–63.

Kasparova, O.V. and Baldokhin, Yu.V., Effect of silicon on electron structure and corrosion-electrochemical behavior of Kh20N20 type phosphorus-containing steel, Zashch. Met., 2002, vol. 38, no. 5, pp. 463–469.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Muravev

About this article

Cite this article

Maznichevskii, A.N., Goikhenberg, Y.N. & Sprikut, R.V. Influence of Silicon, Boron and Rare-Earth Metals on Corrosion Resistance of Austenitic Chromium-Nickel Steel. Steel Transl. 50, 841–847 (2020). https://doi.org/10.3103/S0967091220120098

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220120098