Abstract

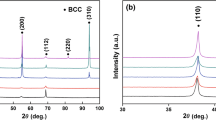

The refractory high-entropy ceramics, TiZrHfNbTaBx (x = 0, 0.1, 1, 10), which vary from high-entropy alloys to high-entropy ceramics depending on the B-content, were fabricated using the arc-melting method. TiZrHfNbTa (x = 0), TiZrHfNbTaBx (x = 0–1), and (TiZrHfNbTa)B2 (x = 10) showed BCC, BCC with MB (M = Ti, Zr, Hf, Nb, Ta), and MB2 structures, respectively. The Vickers hardness and Young’s modulus of these materials increased with an increasing B-content because these ceramic properties are superior to those of metals. The weight gain during oxidation, measured using thermogravimetric analysis, revealed that the highest and lowest weight gains were observed for TiZrHfNbTaB and (TiZrHfNbTa)B2, respectively. Their weight gain depends on their crystal structures rather than their B-contents.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during the current study are available from the corresponding author on reasonable request.

References

W.G. Fahrenholtz, G.E. Hilmas, I.G. Talmy, J.A. Zaykoski, J. Am. Ceram. Soc. (2007). https://doi.org/10.1111/j.1551-2916.2007.01583.x

R. Inoue, Y. Arai, Y. Kubota, Y. Kogo, K. Goto, J. Mater. Sci. (2018). https://doi.org/10.1007/s10853-018-2601-0

S.-Q. Guo, J. Eur. Ceram. Soc. (2009). https://doi.org/10.1016/j.jeurceramsoc.2008.11.008

M.M. Opeka, I.G. Talmy, J.A. Zaykoski, J. Mater. Sci. (2004). https://doi.org/10.1023/B:JMSC.0000041686.21788.77

Y. Arai, R. Inoue, K. Goto, Y. Kogo, Ceram. Int. (2019). https://doi.org/10.1016/j.ceramint.2019.05.065

W.G. Fahrenholtz, J. Am. Ceram. Soc. (2007). https://doi.org/10.1111/j.1551-2916.2006.01329.x

Y. Kubota, H. Tanaka, Y. Arai, R. Inoue, Y. Kogo, K. Goto, J. Eur. Ceram. Soc. (2017). https://doi.org/10.1016/j.jeurceramsoc.2016.10.034

Y. Kubota, M. Yano, R. Inoue, Y. Kogo, K. Goto, J. Eur. Ceram. Soc. (2018). https://doi.org/10.1016/j.jeurceramsoc.2017.11.024

D. Sciti, L. Silvestroni, J. Eur. Ceram. Soc. (2012). https://doi.org/10.1016/j.jeurceramsoc.2011.10.032

F. Monteverde, R. Savino, J. Eur. Ceram. Soc. (2007). https://doi.org/10.1016/j.jeurceramsoc.2007.02.201

R. Inoue, Y. Arai, Y. Kubota, J. Ceram. Int. (2017). https://doi.org/10.1016/j.ceramint.2017.03.129

R. Inoue, Y. Arai, Y. Kubota, Y. Kogo, K. Goto, J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2017.10.034

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. (2004). https://doi.org/10.1002/adem.200300567

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Prog. Mater. Sci. (2014). https://doi.org/10.1016/j.pmatsci.2013.10.001

C. Oses, C. Toher, S. Curtarolo, Nat. Rev. Mater. (2020). https://doi.org/10.1038/s41578-019-0170-8

B. Ye, T. Wen, D. Liu, Y. Chu, J. Corr. Sci. (2019). https://doi.org/10.1016/j.corsci.2019.04.001

J. Gild, Y. Zhang, T. Harrington, S. Jiang, T. Hu, M.C. Quinn, W.M. Mellor, N. Zhou, K.J. VecchioLuo, Sci. Rep. (2016). https://doi.org/10.1038/srep37946

Y. Arai, M. Saito, A. Samizo, R. Inoue, K. Nishio, Y. Kogo, J. Ceram. Int. (2021). https://doi.org/10.1016/j.ceramint.2021.08.055

AtomWork, https://crystdb.nims.go.jp/crystdb/search-materials. Accessed 23 April 2022

R.R. Eleti, N. Stepanov, N. Yurchenko, D. Klimenko, S. Zherebtsov, J. Scr. Mater. (2021). https://doi.org/10.1016/j.scriptamat.2021.113927

X. OuYang, F. Yin, J. Hu, Y. Liu, Z. Long, JPED (2017). https://doi.org/10.1007/s11669-017-0603-2

H. Okamoto, JPED (2008). https://doi.org/10.1007/s11669-008-9400-2

S. Okada, K. Kudou, I. Higashi, T. Lundström, J. Cryst. Growth (1993). https://doi.org/10.1016/S0022-0248(07)80109-6

Acknowledgments

This study was supported by the Japan Society for the Promotion of Science (JSPS) KAKENHI: Grant-in-Aid for Research Activity Start-up (19K23496) and Grant-in-Aid for Early-Career Scientists (20K14613) by the Ministry of Education, Culture, Sports, Science, and Technology (MEXT, Japan). Authors also would like to thank Prof. Ryuji Tamura (Tokyo University of Science) for material processing (fabrication of TiZrHfNbTaBx by arc-melting).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arai, Y., Saito, M. & Kogo, Y. Material design for TiZrHfNbTaBx: A boundary material of refractory high-entropy alloys and ceramics. MRS Advances 7, 848–852 (2022). https://doi.org/10.1557/s43580-022-00337-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-022-00337-9