Abstract

Magnesiothermic reduction was applied to porous silica glass grains with a characteristically interconnected pore structure. The prepared porous silicon maintained the morphology with pore size of approximately 30–40 nm, which was derived from the nanostructure of the starting silica glass. Medium-sized grains of the silica glass produced the largest silicon yield. This result could be explained based on the diffusion-controlled reaction mechanism, involving the reaction of SiO2 with Mg2Si to produce silicon. The electrochemical behavior was investigated using a coin-type cell composed of the prepared porous silicon–carbon mixtures and lithium foil electrodes. The initial charge and discharge capacities reached 1382 and 1187 mAh g−1, respectively, which were close to the theoretical value (1329 mAh g−1). After 50 charge/discharge cycles, 80% of the initial capacity is maintained. These results indicate that porous silicon derived from porous silica glass can be employed as an anode material for lithium-ion batteries.

Graphical abstract

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available from the corresponding author KK upon request.

References

B.R. Bathey, M.C. Cretella, Review solar-grade silicon. J. Mater. Sci. 17, 3077–3096 (1982)

M. Nagamori, I. Malinsky, A. Claveau, Thermodynamics of the Si-C-O system for the production of silicon carbide and metallic silicon. Metall. Trans. B 17, 503–514 (1986)

D. Lynch, Winning the global race for solar silicon. J. Miner. Met. Mater. Soc. 61, 41–48 (2009)

Y. Iwadate, K. Ohgane, T. Ohkubo, Magnesiothermic reduction of silicon dioxide to obtain fine silicon powder in molten salt media: analysis of reduction mechanism. Electrochem. 86(4), 198–201 (2018)

K. Prabriputaloong, M.R. Piggott, Reduction of SiO2 by molten Al. J. Am. Ceram. Soc. 56, 184–185 (1973)

H.D. Banerjee, S. Sen, H.N. Acharya, Investigations on the production of silicon from rice husks by the magnesium method. Mater. Sci. Eng. 52(2), 73–179 (1982)

D.N. Bose, P.A. Govindacharyulu, H.D. Banerjee, Large grain polycrystalline silicon from rice husk. Sol. Energy Mater. 7(3), 319–321 (1982)

L. Canham, Porous Silicon formation by porous silica reduction, in Handbook of Porous Silicon. ed. by L. Canham (Springer, Cham, 2018), pp.99–109

Y. Cai, S.M. Allan, K.H. Sandhage, F.M. Zalar, Three-dimensional magnesia-based nanocrystal assemblies via low-temperature magnesiothermic reaction of diatom microshells. J. Am. Cer. Soc. 88, 2005–2010 (2005)

Z. Bao, M.R. Weatherspoon, S. Shian, Y. Cai, P.D. Graham, S.M. Allan, G. Ahmad, M.B. Dickerson, B.C. Church, Z. Kang, H.W. Abernathy III., C.J. Summers, M. Liu, K.H. Sandhage, Chemical reduction of three-dimensional silica micro-assemblies into microporous silicon replicas. Nature 446, 172–175 (2007)

Z. Bao, E.M. Ernst, S. Yoo, K.H. Sandhage, Syntheses of porous self-supporting metal-nanoparticle assemblies with 3D morphologies inherited from biosilica templates (diatom frustules). Adv. Mat. 21, 474–478 (2009)

E.K. Richman, C.B. Kang, T.B. Brezesinski, S.H. Tolbert, Ordered mesoporous silicon through magnesium reduction of polymer template silica thin films. Nano Lett. 8, 3075–3079 (2008)

M. Ibisate, D. Golmayo, C. López, Silicon direct opals. Adv. Mat. 21, 2899–2902 (2009)

J. Zhu, J. Wu, Y. Wang, C. Meng, Synthesis and characterization of mesoporous silicon directly from pure silica sodalite single crystal. J. Mater. Sci. 45, 6769–6774 (2010)

Y. Shi, F. Zhang, Y.-S. Hu, X. Sun, Y. Zhang, H.I. Lee, L. Chen, G. Stucky, Low-temperature pseudomorphic of ordered hierarchical macro-mesoporous SiO2/C nanocomposite to SiC via magnesiothermic reduction. J. Am. Chem. Soc. 132, 5552–5553 (2010)

L. Pallavidino, M. Liscidini, A. Virga, A. Chiodoni, E. Descrovi, J. Cos, L.C. Andreani, C.F. Pirri, F. Geobaldo, F. Giorgis, Synthesis of amorphous silicon/magnesia based direct opals with tunable optical properties. Opt. Mater. 33, 563–569 (2011)

K. Chen, Z. Bao, J. Shen, G. Wu, B. Zhou, K.H. Sandhage, Freestanding monolithic silicon aerogels. J. Mat. Chem. 22, 16196–16200 (2012)

J. Fang, C.B. Kang, Y. Huang, S.H. Tolbert, L. Pilon, Thermal conductivity of ordered mesoporous monocrystalline silicon thin films made from magnesium reduction of polymer-templated silica. J. Phys. Chem. C 116, 12926–12933 (2012)

D.J. Lee, H. Lee, M.-H. Ryou, G.-B. Han, J.-N. Lee, J. Song, J. Choi, K.Y. Cho, Y.M. Lee, J.-K.B.H. Meekins, Y.-C. Lin, J.S. Manser, K. Manukyan, A.S. Mukasyan, P.V. Kamat, P.J. McGinn, Photoactive porous silicon nanopowder. ACS Appl. Mater. Interfaces 5, 2943–2951 (2013)

D.J. Lee, H. Lee, M.-H. Ryou, G.-B. Han, J.-N. Lee, J. Song, J. Choi, K.Y. Cho, Y.M. Lee, J.-K. Park, Electrospun three-dimensional mesoporous silicon nanofibers as an anode material for high-performance lithium secondary batteries. ACS Appl. Mater. Interfaces 5, 12005–12010 (2013)

X. Ji, G. He, C. Andrei, L.F. Nazar, Gentle reduction of SBA-15 silica to its silicon replica with retention of morphology. RSC Adv. 4, 22048–22052 (2014)

M. Waitzinger, M. Elsaesser, R.J.F. Berger, J. Akbarzadeh, H. Peterlik, N. Hüsing, Self-supporting hierarchically organized silicon networks via magnesiothermic reduction. Monatsh. Chem. 147, 269–278 (2016)

N.H. Hai, I. Grigoriants, A. Gedanke, Converting Stöber silica and Mediterranean sand to high surface are silicon be a reaction under autogenic pressure at elevated temperatures. J. Phys. Chem. C 113, 10521–10526 (2009)

L. Batchelor, A. Loni, L.T. Canham, M. Hasan, J.L. Coffer, Manufacture of mesoporous silicon from living plants and agricultural waste: an environmentally friendly and scalable process. SILICON 4, 259–266 (2012)

A. **ng, S. Tian, H. Tang, D. Losic, Z. Bao, Mesoporous silicon engineered by the reduction of biosilica from rice husk as a high performance anode for lithium ion batteries. RSC Adv. 3, 10145–10149 (2013)

D.S. Jung, M.-H. Ryou, Y.J. Sung, S.B. Park, J.W. Choi, Recycling rice husks for high capacity lithium battery anodes. Proc. Natl. Acad. Sci. U.S.A. 110, 12229–12234 (2013)

Z. Favors, W. Wang, H.H. Bay, Z. Mutlu, K. Ahmed, C. Liu, M. Ozkan, C.S. Ozkan, Scalable synthesis of nano-silicon from beach sand for long cycle life Li-ion batteries. Sci. Rep. 4, 5623 (2014)

J. Petrack, S. Jost, J. Boenigk, M. Epple, Magnesiothermic conversion of the silica-mineralizing golden algae Mallomonas caudata and Synura petersenii to elemental silicon with high geometric precision. Beilstein J. Nanotechnol. 5, 554–560 (2014)

W. Chen, Z. Fan, A. Dhanabalan, C. Chen, C. Wang, Mesoporous silicon anodes prepared by magnesiothermic reduction for lithium ion batteries. J. Electrochem. Soc. 158(9), A1055–A1059 (2011)

M. Ge, X. Fang, J. Rong, C. Zhou, Review of porous silicon preparation and its application for lithium-ion battery anodes. Nanotechnology 24, 422001 (2013)

L. Zeng, R. Liu, L. Han, F. Luo, X. Chen, J. Wang, Q. Qian, Q. Chen, M. Wei, Preparation of a Si/SiO2-ordered-mesoporous-carbon nanocomposite as an anode for high-performance lithium-ion and sodium-ion batteries. Chem. Eur. J. 24, 4841–4848 (2018)

D. T. Ngo, H. T. T. Le, X.-M. Pham, Ji-W. Jung, N. H. Vu, J. G. Fisher, W.-B. Im, Il-D. Kim, C.-J. Park, Highly porous coral-like silicon particles synthesized by an ultra-simple thermal-reduction method. J. Mater. Chem. A 6, 2834–2846 (2018)

J. Entwistle, A. Rennie, S. Patwardhan, A review of magnesiothermic reduction of silica to porous silicon for lithium-ion battery applications and beyond. J. Mater. Chem. A 6, 18344–18356 (2018)

M. Cui, L. Wang, X. Guo, E. Wang, Y. Yang, T. Wu, D. He, S. Liu, H. Yu, Designing of hierarchical mesoporous/microporous silicon-based composite anode material for low-cost high-performance lithium-ions batteries. J. Mater. Chem. A 7, 3874–3881 (2019)

G. Zhu, W. Luo, L. Wang, W. Jiang, J. Yang, Silicon: toward eco-friendly reduction techniques for lithium-ion battery applications. J. Mater. Chem. A 7, 24715–24737 (2019)

J. Tang, Q. Yin, Q. Wang, Q. Li, H. Wang, Z. Xu, H. Yao, J. Yang, X. Zhou, J.-K. Kim, L. Zhou, Two-dimensional porous silicon nanosheets as anode materials for high performance lithium-ion batteries. Nanoscale 11, 10984–10991 (2019)

Z. Yang, Y. Du, G. Hou, Y. Ouyang, F. Ding, F. Yuan, Nanoporous silicon spheres preparation via a controllable magnesiothermic reduction as anode for Li-ion batteries. Electrochim. Acta 329, 135141 (2020)

Y. Zhang, R. Zhang, S. Chen, H. Gao, M. Li, X. Song, H.L. **n, Z. Chen, Diatomite-derived hierarchical porous crystalline-amorphous network for high-performance and sustainable Si anodes. Adv. Funct. Mater. 30, 2005956 (2020)

G.G. Eshetu, E. Figgemeier, Confronting the challenges of next-generation silicon anode-based lithium-ion batteries: Role of designer electrolyte additives and polymeric binders. Chemsuschem 12, 2515–2539 (2019)

K. Uehira, A. Okada, H. Shiomi, T. Wakasugi, K. Kadono, Preparation of porous silicon from porous silica glass via magnesiothermic reduction. Chem. Lett. 45, 1171–1173 (2016)

T. Yazawa, Present status and future potential of preparation of porous glass and its application. Key Eng. Mater. 115, 125–146 (1996)

D. Enke, F. Janowski, W. Schwieger, Porous glasses in the 21th century—A short review. Microporous Mesoporous Mater. 19, 19–30 (2003)

Y. Mao, J.J. Han, Z.J. Zhou, X.J. Zhao, M.-C. Wang, Fabrication of a nanoporous Na2O-B2O3-SiO2 glass plate with controlled pore size. Phys. Chem. Glasses 54, 187–194 (2013)

K. Matsubara, H. Shiomi, T. Shiono, A. Okada, T. Wakasugi, K. Kadono, Porous silicon prepared from monolithic porous silica glass using a two-step magnesiothermic reduction. Int. J. Ceram. Eng. Sci. 2, 310–319 (2020)

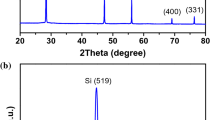

Diffraction data of crystals were cited from PDF#27-1402 for Si, PDF#35-0773 for Mg2Si, and 45-0946 for MgO.

T. Henmi, T. Shiono, K. Matsubara, T. Kiyomura, H. Kurata, T. Wakasugi, A. Okada, K. Kadono, Controlled preparation of silicon and magnesium silicide on silica glass substrate through magnesiothermic reduction. Int. J. Ceramic Eng. Sci. 2, 66–75 (2020)

Y. Tsuboi, S. Ura, K. Takahiro, T. Henmi, A. Okada, T. Wakasugi, K. Kadono, Magnesiothermic reduction of silica glass substrate—Chemical states of silicon in the generated layers. J. Asian Ceram. Soc. 5, 341–349 (2017)

I. Gutman, I. Gotman, M. Shapiro, Kinetics and mechanism of periodic structure formation at SiO2/Mg interface. Acta Mater. 54, 4677–4684 (2006)

I. Gutman, L. Klinger, I. Gotman, M. Shapiro, Model for evolution of periodic layered structure in the SiO2/Mg system. Solids State Ionics 180, 1350–1355 (2009)

Y.C. Chen, J. Xu, X.H. Fan, X.F. Zhang, L. Han, D.Y. Lin, C. Uher, The mechanism of periodic layer formation during solid-state reaction between Mg and SiO2. Intermetallics 17, 920–926 (2009)

K. Omote, Y. Ito, S. Kawamura, Small angle x-ray scattering for measuring pore-size distributions on porous low-κ films. Appl. Phys. Lett. 82, 544–546 (2003)

K. Kubota, S. Shimadzu, N. Yabuuchi, S. Tominaka, S. Shiraishi, M. Abreu-Sepulveda, A. Manivannan, K. Gotoh, M. Fukunishi, M. Dahbi, S. Komada, Structural analysis of sucrose-derived hard carbon and correlation with the electrochemical properties for lithium, sodium, and potassium insertion. Chem. Mater. 32, 2961–2977 (2020)

H. Takahara, T. Shoji, Y. Ito, Chemical state analysis by X-ray emission spectroscopy. Rigaku J. 38(1), 13–21 (2022)

Acknowledgments

The authors are grateful to Mr. Yuji Shiramata in Product Division, Rigaku Corporation, for the measurements and data analyses of SAXS. Deguchi, Shinohara, and Kadono thank members in AIST for the technical support of the electrochemical experiments.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

MD performed all the experiments, preparation and characterization of samples, and electrochemical experiments, except for the measurements of pore size distributions and XES. KS performed the preparation of porous glasses and samples. HK designed and supervised the study of the electrochemical characterization part. KK (Kuratani) discussed the results of the electrochemical characterization. HT performed the characterization of samples by means of SAXS and XES measurements, and interpreted the results. HS performed the measurements using the surface area and porosity analyzer. AO reviewed the edited manuscript and discussed the revision. KK (Kadono) conceptualized and supervised the study, and wrote the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Deguchi, M., Shinohara, K., Kobayashi, H. et al. Preparation of porous silicon using magnesiothermic reduction of porous silica glass and electrode characteristics for lithium-ion batteries. Journal of Materials Research 39, 1758–1769 (2024). https://doi.org/10.1557/s43578-024-01344-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-024-01344-2