Abstract

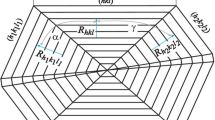

5wt%TiB2/Al-4.5Cu-0.18 V composite materials were successfully prepared by an in-situ aluminothermic reaction assisted by mechanical agitation. The effect of V on the morphology of TiB2 particles in the Al-4.5Cu-0.18 V matrix was studied by field emission scanning electron microscopy and computer statistical software. It was found that the morphology of TiB2 particles has hexagonal prism-shaped with a small aspect ratio, chamfered hexagonal prism and a few irregular shapes, and its size was about 0–1 μm. There was vanadium-rich shell on the surface of TiB2 particles, which hinder the diffusion of atoms and affect the growth process of TiB2 particles. The adsorption energies of V on different crystal planes of TiB2 were calculated by first-principles, showing that V can be preferentially adsorbed on the {10\(\overline{1 }\)0} planes. Moreover, the composite tensile properties of the Al-4.5Cu-0.18 V matrix could be greatly improved by adding 5wt% TiB2.

Graphical abstract

Similar content being viewed by others

References

Q. Gao, S. Wu, S. Lü, X. Duan, P. An, Preparation of in-situ 5 vol% TiB2 particulate reinforced Al–4.5Cu alloy matrix composites assisted by improved mechanical stirring process. Mater. Des. 94, 79 (2016)

R. Du, Q. Gao, S. Wu, S. Lü, X. Zhou, Influence of TiB2 particles on aging behavior of in-situ TiB2/Al-4.5Cu composites. Mater. Sci. Eng. A 721, 244 (2018)

J. Liu, Z. Liu, Z. Dong, X. Cheng, Q. Zheng, J. Li, S. Zuo, Z. Huang, Y. Gao, J. **ng, Q. Han, On the preparation and mechanical properties of in situ small-sized TiB2/Al-4.5Cu composites via ultrasound assisted RD method. J. Alloy. Compd. 765, 1008 (2018)

T. Xu, X. Ma, L. Zhang, M. Li, S. Zhou, H. Wu, Z. Zhu, Enhancement of load transfer by interfacial bonding in Al-Cu-Mg joints under the in-situ synergistic effect of carbon nanotubes and silicon nitride. Mater. Charact. 191, 112144 (2022)

Y.-Y. Gao, F. Qiu, Q. Zou, J.-G. Chu, B.-X. Dong, X. Han, H.-Y. Yang, B. Jiang, Q.-C. Jiang, Controlling the sizes of in-situ TiC nanoparticles for high-performance TiC/Al–Cu nanocomposites. Ceram. Int. 47(20), 28584 (2021)

Y. Chen, S. Song, S. Zhu, X. Cui, F. Zhao, Selective laser remelting of in-situ Al2O3 particles reinforced AlSi10Mg matrix composite: densification, microstructure and microhardness. Vacuum 191, 110365 (2021)

N. Gangil, A.N. Siddiquee, S. Maheshwari, Aluminium based in-situ composite fabrication through friction stir processing: a review. J. Alloy. Compd. 715, 91 (2017)

M. Karbalaei Akbari, H.R. Baharvandi, K. Shirvanimoghaddam, Tensile and fracture behavior of nano/micro TiB2 particle reinforced casting A356 aluminum alloy composites. Mater. Des. (1980-2015) 66, 150 (2015)

S. Lei, X. Li, Y. Deng, Y. **ao, Y. Chen, H. Wang, Microstructure and mechanical properties of electron beam freeform fabricated TiB2/Al-Cu composite. Mater. Lett. 277, 128273 (2020)

F. Chen, Z. Chen, F. Mao, T. Wang, Z. Cao, TiB2 reinforced aluminum based in situ composites fabricated by stir casting. Mater. Sci. Eng. A 625, 357 (2015)

S. Suresh, Aluminium-titanium diboride (Al-TiB2) metal matrix composites: challenges and opportunities. Procedia Eng. (2012). https://doi.org/10.1016/j.proeng.2012.06.013

H.-Y. Yang, Z.-J. Cai, Q. Zhang, Y. Shao, B.-X. Dong, Q.-Q. Xuan, F. Qiu, Comparison of the effects of Mg and Zn on the interface mismatch and compression properties of 50 vol% TiB2/Al composites. Ceram. Int. 47(15), 22121 (2021)

J. Sun, X. Zhang, Y. Zhang, N. Ma, H. Wang, Effect of alloy elements on the morphology transformation of TiB2 particles in Al matrix. Micron 70, 21 (2015)

J. Sun, X. Wang, L. Guo, X. Zhang, H. Wang, Synthesis of nanoscale spherical TiB2 particles in Al matrix by regulating Sc contents. J. Mater. Res. 34(07), 1258 (2019)

X. Zhang, P. Zhu, L. Zeng, B. Feng, X. Wan, J. Ren, Effect of adding Ce on the hot-tearing susceptibility of the 5TiB2/Al-5Cu composite. Mater. Charact. 168, 110552 (2020)

S. Yang, R. Zhang, H. Liu, J. Li, H. Yan, Effect of La on microstructure and corrosion behavior of 10%TiB2(p)/Al–5%Cu composites. J. Mater. Res. Technol. 9(4), 7047 (2020)

D. Huang, D. Yan, S. Ma, X. Wang, Scandium on the formation of in situ TiB2 particulates in an aluminum matrix. J. Mater. Res. 33(18), 2721 (2018)

F. Meng, Z. Wang, Y. Zhao, D. Zhang, W. Zhang, Microstructures and properties evolution of Al-Cu-Mn alloy with addition of vanadium. Metals 7(1), 10 (2016)

S. Zhu, J.-Y. Yao, L. Sweet, M. Easton, J. Taylor, P. Robinson, N. Parson, Influences of nickel and vanadium impurities on microstructure of aluminum alloys. JOM 65(5), 584 (2013)

J. Sun, F. Wang, Y. Liu, L. Guo, H. Wang, The effect of V on the morphology of TiB2 particles in as-cast aluminum composites. Int. J. Mater. Res. 112(11), 890 (2021)

J. Lai, C. Shi, X.-G. Chen, Effects of V addition on recrystallization resistance of 7150 aluminum alloy after simulative hot deformation. Mater. Charact. 96, 126 (2014)

E. Ghasali, A.H. Pakseresht, M. Alizadeh, K. Shirvanimoghaddam, T. Ebadzadeh, Vanadium carbide reinforced aluminum matrix composite prepared by conventional, microwave and spark plasma sintering. J. Alloy. Compd. 688, 527 (2016)

G.L. Beausoleil, M.E. Parry, K. Mondal, S. Kwon, L.R. Gomez-Hurtado, D. Kaoumi, J.A. Aguiar, Spark plasma sintered, MoNbTi-based multi-principal element alloys with Cr, V, and Zr. J. Alloy. Compd. 927, 167083 (2022)

Q. Zhang, W. Zhang, Y. Liu, B. Guo, Cyclic compressive creep-elastoplastic behaviors of in situ TiB2/Al-reinforced composite. Mater. Sci. Eng. A 666, 1 (2016)

A. Khaliq, A.S. Alghamdi, W. Rajhi, T. Subhani, M. Ramadan, K.S.A. Halim, M. Qian, Thermodynamic and kinetic analyses of the removal of impurity titanium and vanadium from molten aluminum for electrical conductor applications. Metall. Mater. Trans. B 52(5), 3130 (2021)

J. Geng, T. Hong, Y. Shen, G. Liu, C. **a, D. Chen, M. Wang, H. Wang, Microstructural stability of in-situ TiB2/Al composite during solution treatment. Mater. Charact. 124, 50 (2017)

Q. Gao, S. Wu, S. Lü, X. **ong, R. Du, P. An, Effects of ultrasonic vibration treatment on particles distribution of TiB2 particles reinforced aluminum composites. Mater. Sci. Eng. A 680, 437 (2017)

S. Mozammil, J. Karloopia, R. Verma, P.K. Jha, Effect of varying TiB2 reinforcement and its ageing behaviour on tensile and hardness properties of in-situ Al-4.5%Cu-xTiB2 composite. J. Alloy. Compd. 793, 454 (2019)

W. Tian, P. Li, X. Liu, Morphology stability of Al3BC phase in aluminum alloys. J. Alloy. Compd. 583, 329 (2014)

A.M.A. Mohamed, A.M. Samuel, F.H. Samuel, H.W. Doty, Influence of additives on the microstructure and tensile properties of near-eutectic Al–10.8%Si cast alloy. Mater. Des. 30(10), 3943 (2009)

H. Mao, C. Li, Y. Dong, Y. Wang, H. Xu, Q. Yu, Y. Shang, X. Li, Z. Zhao, The effect of Mn on particles morphology and property of 5 wt% TiB2/Al-4.5Cu-0.4Mn alloys. J. Alloy. Compd. 904, 163907 (2022)

B.-X. Dong, H.-Y. Yang, F. Qiu, Q. Li, S.-L. Shu, B.-Q. Zhang, Q.-C. Jiang, Design of TiC nanoparticles and their morphology manipulating mechanisms by stoichiometric ratios: experiment and first-principle calculation. Mater. Des. 181, 107951 (2019)

G. Liu, K. Chen, H. Zhou, J. Tian, C. Pereira, J.M.F. Ferreira, Fast shape evolution of TiN microcrystals in combustion synthesis. Cryst. Growth Des. 6(10), 2404 (2006)

C.S. Ramesh, S. Pramod, R. Keshavamurthy, A study on microstructure and mechanical properties of Al 6061–TiB2 in-situ composites. Mater. Sci. Eng. A 528(12), 4125 (2011)

L. Chen, H.-Y. Wang, D. Luo, H.-Y. Zhang, B. Liu, Q.-C. Jiang, Synthesis of octahedron and truncated octahedron primary Mg2Si by controlling the Sb contents. CrystEngComm 15(9), 1787 (2013)

N. Kubota, J.W. Mullin, A kinetic model for crystal growth from aqueous solution in the presence of impurity. J. Cryst. Growth 152(3), 203 (1995)

A. Majumder, Z.K. Nagy, Prediction and control of crystal shape distribution in the presence of crystal growth modifiers. Chem. Eng. Sci. 101, 593 (2013)

Z. Zhuo, H. Mao, H. Xu, Y. Fu, Density functional theory study of Al/NbB2 heterogeneous nucleation interface. Appl. Surf. Sci. 456, 37 (2018)

Q. Wang, C. Liu, R. Yao, H. Zhu, X. Liu, M. Wang, Z. Chen, H. Wang, First-principles study on the stability and work function of low-index surfaces of TiB2. Comput. Mater. Sci. 172, 109356 (2020)

Acknowledgments

This research work was financially funded by the National Natural Science Foundation of China (51775521); the Natural Science Foundation of Shanxi Province (202103021224179); Shanxi Province Key Research and Development Program International Science and Technology Cooperation Project (201903D421080); Shanxi Province Higher Education Science and Technology Innovation Project (2020L0319).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work. There is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, C., Xu, H., Mao, H. et al. The effect of V on the morphology transformation of TiB2 particles in Al-4.5Cu-0.18 V matrix. Journal of Materials Research 38, 1377–1385 (2023). https://doi.org/10.1557/s43578-023-00896-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-00896-z