Abstract

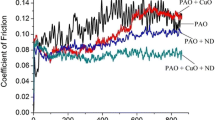

Synergistic compositions of detonation nanodiamond (ND) particles in the form of 100nm aggregates in combination with molybdenum dialkyldithiophosphate were used as additives to 10W40 oils. Ring-on-disk tribological tests were performed under high load conditions using friction pairs with different hardnesses, namely normalized-normalized (“soft/soft”) and normalized-quenched (“soft/hard”) steel samples. For the “soft/hard” steel friction pair NDs provide significant reduction in both the coefficient of friction and wear as well as demonstrate polishing. For the “soft/soft” steel friction pair, however, no difference in the coefficients of friction was observed when the base oil was used with or without ND. In the test with oil containing the ND additive, the wear scar in the disk was wider, but more shallow, than in the test with pure oil. Current tests indicate that the significance of the reduction of friction and wear of the sliding surfaces in the presence of the ND additive in oil strongly depends on the hardness of the friction surfaces and most probably is connected with ND polishing effect.

Similar content being viewed by others

References

Neville, A. Morina, T. Haque, M. Voong, Tribology International 40 (2007) 1680–1695; “Nanolubricants,” Eds. J.-M. Martin and N. Ohmae, Wiley, 2008

M. Ivanov, D.Ivanov, Ch.8 in Ultrananocrystalline Diamond, 2nd Edition, Eds. O.Shenderova, D. Gruen, Elsevier, 2012

Dolmatov V. Yu. J.Superhard Materials, 32, 14–20 (2010)

Zhornik V.I., Kukareko V.A., Belotserkovsky M.A. Nova Science Publishers, 2011

Schrand, A. M. et al. in Safety of Nanoparticles. Nanostructure Science and Technology (ed. Webster, T. J.) 159–187, Springer, 2009

Ivanov M.G., Kharlamov V.V., Buznik V.M., Ivanov D.M., Pavlushko S.G., Tsvetnikov A.K., Friction and Wear, 25 (1), 99 (2004)

M. G. Ivanov, S. V. Pavlyshko, D. M. Ivanov, O. Shenderova, Mater. Res. Soc. Symp. Proc. Vol. 1203, 1203-J17-16 (2010)

M. G. Ivanov, S. V. Pavlyshko, D. M. Ivanov, I. Petrov, O. Shenderova, JVST B, 28, 4, 869–876 (2010)

Ivanov M., Ivanov D., Pavlyshko S.V., Koscheev A. and O.Shenderova, MRS Proceedings, 1452, mrss12-1452-ff08-05 doi:10.1557/opl.2012.1228 (2012).

Ivanov M., Ivanov D., Pavlushko S.V., Petrov I., A. Vargas, G. McGuire, O. Shenderova. Fuller. Nanotub.Carbon Nanost., 20, 4–7, 606–610 (2012)

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ivanov, M., Smirnov, S., Pavlyshko, S. et al. Tribological Properties of Motor Oil with Nanodiamond Additive tested for steel friction surfaces with different hardnesses. MRS Online Proceedings Library 1597, 1597 (2013). https://doi.org/10.1557/opl.2013.1146

Published:

DOI: https://doi.org/10.1557/opl.2013.1146