Abstract

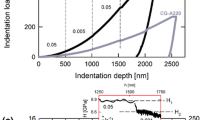

The thermal expansion coefficient (CTE) is a vital design parameter for reducing the thermal-stress-induced structural failure of electronic chips/devices. At the micro- and nano-scale, the typical size range of the components in chips/devices, the CTEs are probably different from that of the bulk materials, but an easy and accurate measurement method is still lacking. In this paper, we present a simple but effective method for determining linear CTEs of micro-scale materials only using the prevalent nanoindentation system equipped with a heating stage for precise temperature control. By holding a constant force on the sample surface, while heating the sample at a constant rate, we measure two height–temperature curves at two positions, respectively, which are close to each other but at different heights. The linear CTE is obtained by analyzing the difference of height change during heating. This method can be applied to study the size effect or surface effect of CTE of embedded micro-scale structures, aiding the failure analysis and structural design in the semiconductor industry.

Similar content being viewed by others

References

H.P. Chi: A simple method for determining linear thermal expansion coefficients of thin films. J. Micromech. Microeng. 12, 548 (2002).

P. Lerch, C.K. Slimane, B. Romanowicz, and P. Renaud: Modelization and characterization of asymmetrical thermal micro-actuators. J. Micromech. Microeng. 6, 134 (1996).

C.S. Pan and W. Hsu: An electro-thermally and laterally driven polysilicon microactuator. J. Micromech. Microeng. 7, 7 (1997).

P.H. Mayrhofer, F. Kunc, J. Musil, and C. Mitterer: A comparative study on reactive and non-reactive unbalanced magnetron sputter deposition of TiN coatings. Thin Solid Films 415, 151 (2002).

M. Bielawski: Residual stress control in TiN/Si coatings deposited by unbalanced magnetron sputtering. Surf. Coat. Technol. 200, 3987 (2006).

H.O. Pierson: Handbook of Refractory Carbides and Nitrides: Properties, Characteristics, Processing and Applications (Noyes Publications, NJ, USA, 1996), p. 186.

W. Fang and J.A. Wickert: Comments on measuring thin-film stresses using bi-layer micromachined beams. J. Micromech. Microeng. 5, 276 (1995).

W. Fang and C.-Y. Lo: On the thermal expansion coefficients of thin films. Sens. Actuators A 84, 310 (1999).

M. Von Arx, O. Paul, and H. Baltes: Process-dependent thin-film thermal conductivities for thermal CMOS MEMS. J. Microelectromechan. Syst. 9, 136 (2000).

W. Fang and J.A. Wickert: Determining mean and gradient residual stresses in thin films using micromachined cantilevers. J. Micromech. Microeng. 6, 301 (1996).

J.J. Vlassak and W.D. Nix: A new bulge test technique for the determination of Young's modulus and Poisson's ratio of thin films. J. Mater. Res. 7, 3242 (1992).

E. Jansen and E. Obermeier: Thermal conductivity measurements on thin films based on micromechanical devices. Diam. Relat. Mater. 5, 644 (1996).

R.V. Jones and J.C.S. Richards: Recording optical lever. J. Sci. Instrum. 36, 90 (1959).

R.E. Kinzly: A new interferometer capable of measuring small optical path differences. Appl. Opt. 6, 137 (1967).

S.F. Jacobs, J.N. Bradford, and J.W. Berthold: Ultraprecise measurement of thermal coefficients of expansion. Appl. Opt. 9, 2477 (1970).

Y. Okada and Y. Tokumaru: Precise determination of lattice parameter and thermal expansion coefficient of silicon between 300 and 1500 K. J. Appl. Phys. 56, 314 (1984).

G. Fug, H. Gasparoux, and J.J. Piaud: Thermal variation apparatus for X-ray diffraction experiments up to 3000 K. J. Phys. E Sci. Instrum. 5, 1222 (1972).

S. Miksic, G. Sherman, and H. Lal: High-temperature X-ray diffraction furnace using a thermal-image technique. J. Appl. Crystallogr. 9, 466 (1976).

K.G. Lyon, G.L. Salinger, C.A. Swenson, and G.K. White: Linear thermal expansion measurements on silicon from 6 to 340 K. J. Appl. Phys. 48, 865 (1977).

Y. Okada: A high-temperature attachment for precise measurement of lattice parameters by Bond's method between room temperature and 1500 K. J. Phys. E Sci. Instrum. 15, 1060 (1982).

K.S. Gadre and T.L. Alford: Crack formation in TiN films deposited on Pa-n due to large thermal mismatch. Thin Solid Films 394, 124 (2001).

Y. Zoo, D. Adams, J.W. Mayer, and T.L. Alford: Investigation of coefficient of thermal expansion of silver thin film on different substrates using X-ray diffraction. Thin Solid Films 513, 170 (2006).

A. Champi, R.G. Lacerda, G.A. Viana, and F.C. Marques: Thermal expansion dependence on the sp2 concentration of amorphous carbon and carbon nitride. J. Non Cryst. Solids 338–340, 499 (2004).

E. Besozzi, D. Dellasega, A. Pezzoli, A. Mantegazza, M. Passoni, and M.G. Beghi: Coefficient of thermal expansion of nanostructured tungsten based coatings assessed by substrate curvature method. Mater. Des. 137, 192 (2018).

D. Olmos, F. Martínez, G. González-Gaitano, and J. González-Benitoa: Effect of the presence of silica nanoparticles in the coefficient of thermal expansion of LDPE. Eur. Polym. J. 47, 1495 (2011).

X.R. Zhang, T.S. Fisher, A. Raman, and T.D. Sands: Linear coefficient of thermal expansion of porous anodic alumina thin films from atomic force microscopy. Nanosc. Microsc. Thermophys. Eng. 13, 243 (2009).

J. González-Benito, E. Castillo, and J.F. Cruz-Caldito: Determination of the linear coefficient of thermal expansion in polymer films at the nanoscale: Influence of the composition of EVA copolymers and the molecular weight of PMMA. Phys. Chem. Chem. Phys. 17, 18495 (2015).

J.H. Zhao, Y. Du, M. Morgen, and P.S. Ho: Simultaneous measurement of Young's modulus, Poisson ratio, and coefficient of thermal expansion of thin films on substrates. J. Appl. Phys. 87, 1575 (2000).

A.M. Russell and B.A. Cook: Coefficient of thermal expansion anisotropy and texture effects in ultra-thin titanium sheet. Scr. Mater. 37, 1461 (1997).

M.M.D. Lima, R.G. Lacerda, J. Vilcarromero, and F.C. Marques: Coefficient of thermal expansion and elastic modulus of thin films. J. Appl. Phys. 86, 4936 (1999).

W. Riethmuller and W. Benecke: Thermally excited silicon microactuators. IEEE Trans. Electron Devices 35, 758 (1988).

R. Feng and R.J. Farris: The characterization of thermal and elastic constants for an epoxy photoresist SU8 coating. J. Mater. Sci. 37, 4793 (2002).

H.C. Liou, P.S. Ho, and R. Stierman: Thickness dependence of the anisotropy in thermal expansion of PMDA-ODA and BPDA-PDA thin films. Thin Solid Films 339, 68 (1999).

C.L. Choy: Chapter 4 Thermal expansivity of oriented polymers. In Developments in Oriented Polymers-1, I.M. Ward, ed. (Applied Science Publishers, London and NJ, England and USA, 1982), pp. 121.

S. Liu, V.S. Chevali, Z. Xu, D. Hui, and H. Wang: A review of extending performance of epoxy resins using carbon nanomaterials. Compos. Part B 136, 197 (2018).

S. Rimdusit and H. Ishida: Development of new class of electronic packaging materials based on ternary systems of benzoxazine, epoxy, and phenolic resins. Polymer 41, 7941 (2000).

Acknowledgment

The author gratefully thanks Professor Zhiwei Shan, Professor Boyu Liu, and Professor Kai Chen at **'an Jiaotong University for the valuable discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, Y., Nie, Z., Ma, C. et al. Simple nanoindentation-based method for determining linear thermal expansion coefficients of micro-scale materials. Journal of Materials Research 35, 3202–3209 (2020). https://doi.org/10.1557/jmr.2020.320

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.320