Abstract

This review aims to consolidate scarce literature on the use of modern nanomechanical testing technique like instrumented nanoindentation in the field of archaeometry materials research. The review showcase on how can the nanoindentation tests provide valuable data about mechanical properties which, in turn, relate to the evolution of ancient biomaterials as well as human history and production methods. This is particularly useful when the testing is limited by confined volumes and small material samples (since the contact size is in the order of few microns). As an emerging novel application, some special considerations are warranted for characterization of archaeometry materials. In this review, potential research areas relating to how nanoindentation is expected to benefit and help improve existing practices in archaeometry are identified. It is expected that these insights will raise awareness for use of nanoindentation at various world heritage sites as well as various museums.

Similar content being viewed by others

References

K. Ryzewski, B.W. Sheldon, S.E. Alcock, M. Mankin, S. Vasudevan, and N. Sinnott-Armstrong: Multiple assessments of local properties, production, and performance in metal objects: An experimental case study from Petra. Jordan. Archaeol. Anthropol. Sci. 3, 173 (2011).

ISO 14577-1, -2, -3, -4 Metallic Materials Instrumented Indentation Tests for Hardness and Material Properties Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

ASTM E2546-07: Standard Practice for Instrumented Indentation Testing (ASTM International, West Conshohocken, Pennsylvania, 2007). www.astm.org.

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Sci. 7, 1564 (1992).

G.M. Erickson, B.A. Krick, M. Hamilton, G.R. Bourne, M.A. Norell, E. Lilleodden, and W.G. Sawyer: Complex dental structure and wear biomechanics in hadrosaurid dinosaurs. Science 338, 98 (2012).

M. Janko, A. Zink, A.M. Gigler, W.M. Heckl, and R.W. Stark: Nanostructure and mechanics of mummified type I collagen from the 5300-year-old Tyrolean Iceman. Proc. R. Soc. B 277, 2301 (2010).

P. Northover, S. Northover, and A. Wilson: Microstructures of ancient and historic silver. In Metal 2013, 16–20 September 2013, (International Council of Museums ICOM-CC, 253, Edinburgh, 2013); pp. 253–260. http://oro.open.ac.uk/37678/.

N. Patzke, A.A. Levin, I.P. Shakhverdova, M. Reibold, W. Kochmann, P. Paufler, and D.C. Meyer: Nanostructured ancient Damascus blades, DMG (2008). (abstract no. 208, session S17). Available at: https://www.dmg-home.org/fileadmin/Konferenzen/DMG-CD/filedir/208_abstract.pdf.

W. Kochmann, M. Reibold, R. Goldberg, W. Hauffe, A.A. Levin, D.C. Eyer, T. Stephan, H. Müller, A. Belger, and P. Paufler: Nanowires in ancient Damascus steel. J. Alloys Compd. 372, L15–L19 (2004).

Y. Li, T. Wu, L. Liao, C. Liao, L. Zhang, G. Chen, and C. Pan: Techniques employed in making ancient thin-walled bronze vessels unearthed in Hubei Province, China. Appl. Phys. A: Mater. Sci. Process. 111, 913 (2013).

B.C. Chakoumakos, W.C. Oliver, G.R. Lumpkin, and R.C. Ewing: Hardness and elastic modulus of zircon as a function of heavy-particle irradiation dose: I. In situ α-decay event damage. Radiat. Eff. Defects Solids 118, 393 (1991).

H. Lerner, X. Du, A. Costopoulos, and M. Ostoja-Starzewski: Lithic raw material physical properties and use-wear accrual. J. Archaeol. Sci. 34, 711 (2007).

G.D. Sanson, S.A. Kerr, and K.A. Gross: Do silica phytoliths really wear mammalian teeth?J. Archaeol. Sci. 34, 526 (2007).

F. Riede and J.M. Wheeler: Testing the ‘Laacher See Hypothesis’: Tephra as dental abrasive. J. Archaeol. Sci. 36, 2384 (2009).

P.L. Manning, L. Margetts, M.R. Johnson, P.J. Withers, W.I. Sellers, P.L. Falkingham, P.M. Mummery, P.M. Barrett, and D.R. Raymont: Biomechanics of dromaeosaurid dinosaur claws: Application of X-ray microtomography, nanoindentation and finite element analysis. Anat. Rec. 292, 1397 (2009).

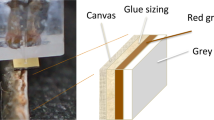

J. Salvant, E. Barthel, and M. Menu: Nanoindentation and the micromechanics of Van Gogh oil paints. Appl. Phys. A: Mater. Sci. Process. 104, 509 (2011).

S.E. Olesiak, M.L. Oyen, M. Sponheimer, J.J. Eberle, and V.L. Ferguson: Ultrastructural mechanical and material characterization of fossilized bone. Mater. Res. Soc. Symp. Proc. 975, 0975–DD03–09 (2006).

S.E. Olesiak, M. Sponheimer, J.J. Eberle, M.L. Oyen, and V.L. Ferguson: Nanomechanical properties of modern and fossil bone. Palaeogeogr., Palaeoclimatol., Palaeoecol 289, 25 (2010).

N.H. Faisal, R. Ahmed, and R.L. Reuben: Indentation testing and its acoustic emission response: Applications and emerging trends. Int. Mater. Rev. 56, 98 (2011).

W.C. Oliver and G.M. Pharr: Nanoindentation in materials research; past, present, and future. MRS Bull. 35, 897 (2010).

D. Tabor: The Hardness of Metals (Oxford Clarendon Press, Oxford, England, 1951); pp. 19–43.

N.K. Mukhopadhyay and P. Paufler: Micro- and nanoindentation techniques for mechanical characterisation of materials. Int. Mater. Rev. 51, 209 (2006).

M.R. VanLandingham: Review of instrumented indentation. J. Res. Natl. Inst. Stand. Technol. 108, 249 (2003).

A.C. Fisher-Cripps: Nanoindentation (Springer, New York, 2002); p. 39.

R. Hill: The Mathematical Theory of Plasticity (Oxford Clarendon Press, Oxford, England, 1950); p. 14.

B.R. Lawn and R. Wilshaw: Review-indentation fracture: Principles and applications. J. Mater. Sci. 10, 1049 (1975).

B.R. Lawn and D.B. Marshall: Hardness, toughness, and brittleness: An indentation analysis. J. Am. Ceram. Soc. 62, 347 (1979).

M.L. Oyen: Analytical techniques for indentation of viscoelastic materials. Philos. Mag. 86, 5625 (2006).

J.B. Pethicai, R. Hutchings, and W.C. Oliver: Hardness measurement at penetration depths as small as 20 nm. Philos. Mag. A 48, 593 (1983).

S. Goel, G. Cross, A. Stukowski, E. Gamsjäger, B. Beake, and A. Agrawal: Designing nanoindentation simulation studies by appropriate indenter choices: Case study on single crystal tungsten. Comput. Mater. Sci. 152, 196 (2018).

A.C. Fischer-Cripps: Nanoindentation, 2nd ed. (Springer-Verlag, New York, 2002); p. 39.

S. Suresh and A. Giannakopoulos: A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 46, 5755 (1998).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 1 (2004).

A.C. Fischer-Cripps: Introduction to Contact Mechanics, 2nd ed. (Springer US, 2007); pp. 77, 175.

K.L. Johnson: Contact Mechanics (Cambridge University Press, England, 1985); p. 84.

I.N. Sneddon: The relation between load and penetration in the axisymmetric boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 (1965).

G.M. Pharr, J.H. Strader, and W.C. Oliver: Critical issues in making small-depth mechanical property measurements by nanoindentation with continuous stiffness measurement. J. Mater. Res. 24, 653 (2009).

NanoBlitz 4D: Available at: http://nanomechanicsinc.com/available-now-nanoblitz-3d-4d/ (accessed September 5, 2017).

O. Jiroušek: Nanoindentation in Materials Science (IntechOpen Limited, London, 2012); p. 259.

A.J. Bushby, V.L. Ferguson, and A. Boyde: Nanoindentation of bone: Comparison of specimens tested in liquid and embedded in polymethylmethacrylate. J. Mater. Res. 19, 249 (2004).

M. Granke, A. Coulmier, S. Uppuganti, J.A. Gaddy, M.D. Does, and J.S. Nyman: Insights into reference point indentation involving human cortical bone: Sensitivity to tissue anisotropy and mechanical behavior. J. Mech. Behav. Biomed. Mater. 37, 174 (2014).

A.K. Bembey, M.L. Oyen, A.J. Bushby, and A. Boyde: Viscoelastic properties of bone as a function of hydration state determined by nanoindentation. Philos. Mag. 86, 5691 (2006).

R.K. Nalla, M. Balooch, J.W. Ager, III, J.J. Kruzic, J.H. Kinney, and R.O. Ritchie: Effects of polar solvents on the fracture resistance of dentin: Role of water hydration. Acta Biomater. 1, 31 (2005).

L. Angker and M.V. Swain: Nanoindentation: Application to dental hard tissue investigations. J. Mater. Res. 21, 1893 (2006).

M. Dudíková, D. Kytýr, T. Doktor, and O. Jiroušek: Monitoring of material surface polishing procedure using confocal microscope. Chem. Listy 105, 790 (2011).

B. Bhushan, W. Tang, and S. Ge: Nanomechanical characterization of skin and skin cream. J. Microsc. 240, 135 (2010).

M.L. Crichton, X. Chen, H. Huang, and M.A.F. Kendall: Elastic modulus and viscoelastic properties of full thickness skin characterised at micro scales. Biomaterials 34, 2087 (2013).

M. Reibold, P. Paufler, A.A. Levin, W. Kochmann, N. Pätzke, and D.C. Meyer: Materials: Carbon nanotubes in an ancient Damascus sabre. Nature 444, 286 (2006).

O. Borrero-Lopez, A. Pajares, P.J. Constantino, and B.R. Lawn: A model for predicting wear rates in tooth enamel. J. Mech. Behav. Biomed. Mater. 37, 226 (2014).

P. Ungar and M. Sponheimer: The diets of early hominins. Science 334, 190 (2011).

B.R. Lawn and R.F. Cook: Probing material properties with sharp indenters: A retrospective. J. Mater. Sci. 47, 1 (2012).

J. Lange, A. Luisier, E. Schedin, G. Ekstrand, and A. Hult: Development of scratch tests for pre-painted metal sheet and the influence of paint properties on the scratch resistance. J. Mater. Process. Technol. 86, 300 (1999).

S.W. Wai: Rapid Assessment of Paint Coatings by Micro and Nano Indentation Methods. Ph.D. thesis, School of Mechanical, Materials and Mechatronic Engineering, University of Wollongong, 2013. Available at: http://ro.uow.edu.au/theses/3873.

R.A. Brand: Biographical sketch: Julius Wolff, 1836–1902. Clin. Orthop. Relat. Res. 468, 1047 (2010).

U. Wolfram and J. Schwiedrzik: Post-yield and failure properties of cortical bone. BoneKEy Rep. 5, 829 (2016).

J. Schwiedrzik, R. Raghavan, A. Bürki, V. LeNader, U. Wolfram, J. Michler, and P. Zysset: In situ micropillar compression reveals superior strength and ductility but an absence of damage in lamellar bone. Nat. Mater. 13, 740 (2014).

M.J. Mirzaali, J.J. Schwiedrzik, S. Thaiwichai, J.P. Best, J. Michler, P.K. Zysset, and U. Wolfram: Mechanical properties of cortical bone and their relationships with age, gender, composition and microindentation properties in the elderly. Bone 93, 196 (2016).

K.S. Anseth, C.N. Bowman, and L. Brannon-Peppas: Mechanical properties of hydrogels and their experimental determination. Biomaterials 17, 1647 (1996).

N.H. Faisal and R. Ahmed: A review of patented methodologies in instrumented indentation residual stress measurements. Recent Pat. Mech. Eng. 4, 138 (2011).

H. Yao, Z. **e, C. He, and M. Dao: Fracture mode control: A bio-inspired strategy to combat catastrophic damage. Sci. Rep. 5, 8011 (2015).

A. Fatima and P.T. Mativenga: On the comparative cutting performance of nature-inspired structured cutting tool in dry cutting of AISI/SAE 4140. Proc. Inst. Mech. Eng., Part B: J. Eng. Manuf. 231, 1941 (2017).

Four student-designed, nature-inspired transportation solutions: Available at: http://makezine.com/2014/06/10/four-student-designed-nature-inspired-transporation-solutions/ (accessed August 20, 2017).

Research showcase on bioinspired design: Available at: http://www3.imperial.ac.uk/newsandeventspggrp/imperialcollege/engineering/newssummary/news_2-2-2016-16-28-13 (accessed August 20, 2017).

P.S. Ungar: Dental evidence for the diests of Plio-Pleistocene hominis. Am. J. Phys. Anthropol. 146, 47 (2011).

D.B. Marshall, R.F. Cook, N.P. Padture, M.L. Oyen, A. Pajares, J.E. Bradby, I.E. Reimanis, R. Tandon, T.F. Page, G.M. Pharr, and B.R. Lawn: The compelling case for indentation as a functional exploratory and characterization tool. J. Am. Ceram. Soc. 98, 2671 (2015).

B.W. Darvell, P.K.D. Lee, T.D.B. Yuen, and P.W. Lucas: A portable fracture toughness tester for biological materials. Meas. Sci. Technol. 7, 954 (1996).

S. Valliappan and C.K. Chee: Aging degradation of mechanical structures. J. Mech. Mater. Struct. 3, 1923 (2008).

ACKNOWLEDGMENTS

All the authors would like to acknowledge the overall experience gained during their research and development through various commercially available nanoindentation machines without which this review would not have been possible. The authors (SG and GC) would like to acknowledge the support of the COST Action MP1303 as well as COST Action 15102 of the Horizon 2020. SG is also grateful to the Centre for Doctoral Training (CDT) in Ultra Precision at Cranfield University which is supported by the EPSRC via Grant Nos. EP/K503241/1 and EP/L016567/1 that provided the motivation for this work. Finally, all the authors are particularly grateful to the Principal Editor (Journal of Materials Research) and the reviewers for their extensive comments and recommendations.

Author information

Authors and Affiliations

Corresponding author

Additional information

This section of Journal of Materials Research is reserved for papers that are reviews of literature in a given area.

Rights and permissions

About this article

Cite this article

Faisal, N.H., Ahmed, R., Goel, S. et al. Future of nanoindentation in archaeometry. Journal of Materials Research 33, 2515–2532 (2018). https://doi.org/10.1557/jmr.2018.280

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.280