Abstract

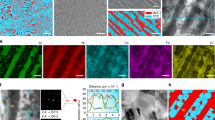

An in situ bulk ultrafine bimodal eutectic Al-Cu-Si composite was synthesized by solidification. This heterostructured composite with microstructural length scale hierarchy in the eutectic microstructure, which combines an ultrafine-scale binary cellular eutectic (α-Al + Al2Cu) and a nanometer-sized anomalous ternary eutectic (α-Al + Al2Cu + Si), exhibits high fracture strength (1.1 ± 0.1 GPa) and large compressive plastic strain (11 ± 2%) at room temperature. The improved compressive plasticity of the bimodal-nanoeutectic composite originates from homogeneous and uniform distribution of inhomogeneous plastic deformation (localized shear bands), together with strong interaction between shear bands in the spatially heterogeneous structure.

Similar content being viewed by others

References

G. He, J. Eckert, W. Löser, and L. Schultz: Novel Ti-base nanostructure-dendrite composite with enhanced plasticity. Nat. Mater. 2, 33 (2003).

J.M. Park, S.W. Sohn, T.E. Kim, K.B. Kim, W.T. Kim, and D.H. Kim: Nanostructure-dendrite composites in the Fe-Zr binary alloy system exhibiting high strength and plasticity. Scr. Mater. 57, 1153 (2007).

D.V. Louzguine, H. Kato, and A. Inoue: High-strength hypereu-tectic Ti-Fe-Co bulk alloy with good ductility. Philos. Mag. Lett. 84, 359 (2004).

E. Ma: Controlling plastic instability. Nat. Mater. 2, 7 (2003).

J.M. Park, T.E. Kim, S.W. Sohn, D.H. Kim, K.B. Kim, W.T. Kim, and J. Eckert: High strength Ni-Zr binary ultrafine eutectic-dendrite composite with large plastic deformability. Appl. Phys. Lett. 93, 031903 (2008).

H. Ma, L.L. Shi, J. Xu, and E. Ma: Chill-cast in situ composites in the pseudo- ternary Mg-(Cu,Ni)-Y glass-forming system: Microstructure and compressive properties. J. Mater. Res. 22, 314 (2007).

J.H. Han, K.B. Kim, S. Yi, J.M. Park, S.W. Sohn, T.E. Kim, D.H. Kim, J. Das, and J. Eckert: Formation of a bimodal eutectic structure in Ti–Fe–Sn alloys with enhanced plasticity. Appl. Phys. Lett. 93, 141901 (2008).

D.V. Louzguine, L.V. Louzguina, H. Kato, and A. Inoue: Investigation of Ti-Fe-Co bulk alloys with high strength and enhanced ductility. Acta Mater. 53, 2009 (2005).

J.M. Park, S.W. Sohn, D.H. Kim, K.B. Kim, W.T. Kim, and J. Eckert: Propagation of shear bands and accommodation of shear strain in the Fe56Nb4Al40 ultrafine eutectic-dendrite com-posite. Appl. Phys. Lett. 92, 091910 (2008).

J. Das, K.B. Kim, F. Baier, W. Löser, and J. Eckert: High-strength Ti-base ultrafine eutectic with enhanced ductility. Appl. Phys. Lett. 87, 161907 (2005).

J.M. Park, D.H. Kim, K.B. Kim, and W.T. Kim: Deformation-induced rotational eutectic colonies containing length-scale het-erogeneity in an ultrafine eutectic Fe83Ti7Zr6B4 alloy. Appl. Phys. Lett. 91, 131907 (2007).

D.V. Louzguine, H. Kato, L.V. Louzguina, and A. Inoue: High-strength binary Ti-Fe bulk alloys with enhanced ductility. J. Mater. Res. 19, 3600 (2004).

L. Shi, H. Ma, T. Liu, J. Xu, and E. Ma: Microstructure and compressive properties of chill-cast Mg-Al-Ca alloys. J. Mater. Res. 21, 613 (2006).

J.M. Park, K.B. Kim, M.H. Lee, W.T. Kim, J. Eckert, and D.H. Kim: High strength ultrafine eutectic Fe-Nb-Al composites with enhanced plasticity. Intermetallics 16, 642 (2008).

D.V. Louzguine, L.V. Louzguina, H. Kato, and A. Inoue: Investigation of high strength metastable hypereutectic ternary Ti–Fe–Co and quaternary Ti–Fe–Co–(V, Sn) alloys. J. Alloys Compd. 434–435, 32 (2007).

J.M. Park, D.H. Kim, K.B. Kim, M.H. Lee, W.T. Kim, and J. Eckert: Influence of heterogeneities with different length scale on the plasticity of Fe-base ultrafine eutectic alloys. J. Mater. Res. 23, 2003 (2008).

L.F. Mondolfo: Alluminum Alloys: Structure and Properties (Butterworths, London, UK1976).

Y. Li, K. Georgarakis, S. Pang, J. Antonowicz, F. Charlot, A. Lemoulec, T. Zhang, and A.R. Yavari: AlNiY chill-zone alloys with good mechanical properties. J Alloys Compd. 447, 346 (2009).

B.A. Sun, M.X. Pan, D.Q. Zhao, W.H. Wang, X.K. **, M.T. Sandor, and Y. Wu: Aluminum-rich bulk metallic glasses. Scr. Mater. 59, 1159 (2008).

T.T. Sasaki, T. Mukai, and K. Hono: A high-strength bulk nanocrystalline Al-Fe alloy processed by mechanical alloying and spark plasma sintering. Scr. Mater. 57, 189 (2007).

P. Villars, A. Prince, and H. Okamoto: Handbook of Ternary Alloy Phase Diagrams (ASM International, Materials Park, OH, 1995).

JCPDFWIN: Version 2.2 (JCPDS, International Center for Diffraction Data, Newton Square, PA, 2001).

R. Elliott: Eutectic Solidification Processing: Crystalline and Glassy Alloys (Butterworths, London, UK, 1983).

K.A. Jackson and J.D. Hunt: Lamellar and rod eutectic growth. Trans. Metall. Soc. AIME 236, 1129 (1966).

P.L. Ferrandini, F.L.G.U. Araujo, W.W. Batista, and R. Caram: Growth and characterization of the NiAl-NiAlNb eutectic structure. J. Cryst. Growth 275, e147 (2005).

J.H. Han, K.B. Kim, S. Yi, J.M. Park, D.H. Kim, S. Pauly, and J. Eckert: Influence of a bimodal eutectic structure on the plastic-ity of (Ti70.5Fe29.5)91Sn9 ultrafine composite. Appl. Phys. Lett. 93, 201906 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to https://www.mrs.org/jmr_policy

Rights and permissions

About this article

Cite this article

Park, J.M., Mattern, N., Kühn, U. et al. High-strength bulk Al-based bimodal ultrafine eutectic composite with enhanced plasticity. Journal of Materials Research 24, 2605–2609 (2009). https://doi.org/10.1557/jmr.2009.0297

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2009.0297