Abstract

It is well known and accepted that the viscosity of CMP-slurries has an effect on polishing results. Even though the literature on rheology recognizes that viscosity is not always constant and the slurry can show non-Newtonian behavior or even dilatant effects, all calculations have been performed with constant viscosity.

However, the “real” viscosity of a CMP-slurry during polishing can change significantly with shear rate.

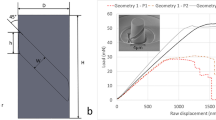

The typical equipment for viscosity measurement is based on a rotating cylinder or a plate. But even with a plate system it is only possible to reach a shear rate range up to 50,000 1/sec. A calculation of the shear rate between the wafer and the polishing pad is based on a relative velocity of 1 m/sec and a distance between the wafer and the pad of 20 μm; this correlates to a shear rate of 50,000 1/sec. If parts of the polishing pad come closer to the wafer or especially closer to the edge of structures on the wafer (for example 1 μm), the shear rate will increase locally to 1,000,000 1/sec.

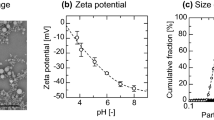

When the shear rate is high enough, viscosity depends mostly on hydrodynamic factors like viscosity of continuos phase, solids content, particle size, particle size distribution and shape of the particles.

The shape of fumed metal oxides is controlled during the synthesis in the flame process. But the slurry-making process is also responsible for particle size distribution, shape of the particle and the high shear rate viscosity of the CMP-slurry.

The high shear rate viscosity of different silica slurries in dependence from BET-surface area, used milling energy, concentration and preparation direction was measured in this investigation.

Similar content being viewed by others

References

A. Einstein, Ann. Phys. 19, 289–306 (1906) and Ann. Phys. 34, 591–592 (1911).

F. Preston, J. Soc. Glass Technol., 11, p.214, 1927

W.-T. Tseng and Y.-L. Wang, J. Electrochem. Soc., 144, No.2, p.L15, 1995

B. Zhao and F.G. Shi, Proc. CMP-MIC, p.13, 1999

A. Philipossian and M. Hanazono, “Tribology, Fluid Dynamics and Removal Rate Characterization of Novel Slurries for ILD Polish Applications” in Proceedings of CMP Special Committee Conference, 2001, San Fransisco, CA. www.innovative-planarization.com/Presentations/presentations.html

B. Mullany and G. Byrne, Proceedings of the Seventeenth International VLSI Multilevel Interconnection Conference (VMIC), June 27–29, 2000, pp. 515–521

M. R. Oliver, R. E. Schmidt and M. Robinson, “CMP Pad Surface Roughness and CMP Removal Rate”, presented at ECS Fall Conference, October 23, 2000, Phoenix, AZ. www.rodel.com/common/ca/list.asp?caid=25&groupname=2000

A. Philipossian, „CMP Consumables”, CMP-MIC Tutorial, 2001, Santa Clara, CA. www.innovative-planarization.com/Presentations/presentations.html

A. S. Lawing and R. Rhoades, “Pad/Slurry/Conditioning Interactions in Oxide CMP”presented at CMPUG meeting, December 2001 http://www.rodel.com/common/ca/list.asp?caid=25&groupname=2000

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lortz, W., Menzel, F., Brandes, R. et al. News from the M in CMP - Viscosity of CMP Slurries, a Constant?. MRS Online Proceedings Library 767, 17 (2003). https://doi.org/10.1557/PROC-767-F1.7

Published:

DOI: https://doi.org/10.1557/PROC-767-F1.7