Abstract

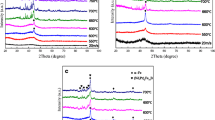

Melt-spun Nd2Fe14B (2-14-1) ribbons were produced under active vacuum and different partial pressures of inert gases of Ar and He. Microstructure and thermal analyses were performed to understand the microstructural evolution and glass formability (GF) of the ribbons. He atmosphere enhances the quenchability of the ribbons over Ar and vacuum. Ribbons made under 250 Torr He have more uniform microstructure and smoother surfaces than those under 760 Torr He. The higher quenchability induced by He, which increases the interfacial heat transfer coefficient between the melt and rotating wheel during melt spinning, is due to its higher thermal conductivity compared to Ar. The lower pressure stabilizes the turbulence between the melt-pool and Cu wheel, enhancing the heat transfer resulting in a more uniform quench. As a result, a more uniform ribbon microstructure can be obtained at relatively low wheel speeds.

Similar content being viewed by others

References

R. Pond and R. Maddin, Transaction of the Metal Society AIEM, 245, (1969), p.2475–2476.

M. C. Narasimham, U.S. Patent No. 4212343, 1980.

F. Fogiku et al., Rapidly Solidified Alloys and Their Mechanical and Magnetic Propertied. MRS, B.C. Giessen et al. (eds.) Vol.58,(1986), p. 15

S. Krishnamurthy, P.R. Smith and J.G. Paine, Proc. Of Enhanced Propertied in Structural Metals via Rapid Solidification, F.H. Froes (ed.) (ASM. Orlando, FL. Oct. 1986), p.67

Y.L. Tang, S. K. Guan, N. F. Shen and D. S. Zhao, J. Mater. Sci. Lett., 12 (22) p. 1749(1993)

H. Jones, Proc. of Enhanced Propertied in Structural Metals via Rapid Solidification, F.H. Froes (ed.) (ASM. Orlando, FL. Oct. 1986), p.77

T.H. Kanekiyo, M. Uehara and S. Hirosawa, Abstract in 7th Joint MMM-Intermagnetics Conference, San Francisco, CA (1998), p.20.

D. J. Branagan, Ph.D. Thesis, Iowa State University, 1995

M.J. Kramer, C.P. Li, K.W. Dennis and R.W. McCallum, J. Applied Physics, 83(11) p.6631 (1998)

D. J. Branagan, M. J. Kramer, R. W. McCallum J. Alloys Compd., 244, p.27–39 (1996)

D.J. Branagan, and R.W. McCallum, J. Alloys and Compd., 218, p.143(1995)

M. J. Kramer, C.P. Li, K. W. Dennis, R.W. McCallum et al. J. Applied Phys. 81, p.4459(1997)

B. Abramzon and C. Elta, Numerical Method in Thermal Problems, Vol. 2, R.W. Lewis, K. Morgan and B.A. Shrefler (eds.), Swansea, Pineridge: 1981, pp. 1145

H. B. Crawford and R. J. Kepler (eds.) Chemical Engineer’s Handbook, McGraw-Hill Inc., 1973, pp. 3–244

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kramer, M.J., Tang, Y., Dennis, K.W. et al. Effects of Quenching Environment on the Structure of Melt- Spun Nd2Fe14B. MRS Online Proceedings Library 577, 57–62 (1999). https://doi.org/10.1557/PROC-577-57

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-577-57