Abstract

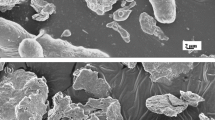

Since the Lanxide process was advanced for forming of Al2O3 ceramic composite by directed oxidation of Al alloys, much work has been done with various mechanisms being proposed. The mechanisms have claimed that only certain dopants are essential to the growth process. Nevertheless, no united consensus has yet been reached. In the present work, Al alloy containing 5% Mg was oxidised in air for 12 hours at 1150°C with or without surface dopants of MgO or Pd. The resultant composites showed very different microstructures. Without any surface do**, the alloy did not develop any portion of composite as the initial intimate oxide film stops further oxidation. This intimate oxide film can either be broken off by mechanical means or penetrated by reaction with surface dopants, so that the composite can grow and develop. The results show that the previously reported incubation time is not only related to reaction processes but also to the initial mechanical disturbances. Do** with Pd made the composite darker in colour as the grains of the alumina ceramic matrix and inclusions of Al metal are finer. This shows that Pd may make the top oxide layer less intimate, and more nucleation sites are therefore available for oxidation. A new model is presented for oxide sustained growth based on the existence of oxygen active top surface layer and the capillary flow of molten metal around ceramic phase.

Similar content being viewed by others

References

M.S. Newkirk, A.W. Urquhart, H.R. Zwicker & E. Breval, J. Mater. Res. 1, 81 (1986).

O. Salas, H. Ni, V. Jayaram, K.C. Vlach, C.G. Levi & R. Mehrabian, J. Mater. Res. 6, 1964 (1991).

P. **ao and B. Derby, Proc. British Ceram. Soc. 50, 191 (1993).

P. **ao and B. Derby, J. Am. Ceram. Soc., 77, 1761 (1994).

E. Breval, K. Aghjanian, J.P. Biel & S. Antolin, J. Am. Ceram. Soc. 76, 1865 (1993).

E. Manor, H. Ni, C.G. Levi & R. Mehrabian, J. Am. Ceram. Soc. 76, 1777 (1993).

M. Backhaus-Ricoult and R. Dieckmann, Ber. Bunsebges. Phys. Chem., 90, 690 (1986).

P. **ao and B. Derby, J. Am. Ceram. Soc., 77, 1771 (1994).

P. **ao and B. Derby, J. Euro. Ceram. Soc. 12, 185 (1993).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Qin, CD., Lai, M.O., Cotterell, B. et al. Microstructure and Growth Mechanism of Al2O3/Al Ceramic Matrix Composite Made by Directed Oxidation of Al Alloys. MRS Online Proceedings Library 365, 133–138 (1994). https://doi.org/10.1557/PROC-365-133

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-365-133