Abstract

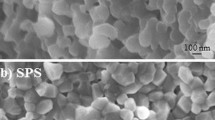

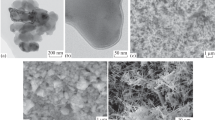

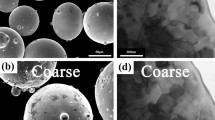

Spark plasma sintering (SPS) of a codoped α-alumina powder has been investigated at temperatures between 850 and 1200 °C. The “grain size versus relative density” trajectory showed a significant grain growth as soon as the residual porosity closed. The densification mechanism was determined by anisothermal (investigation of the heating part of a SPS run) and isothermal methods. It was proposed that grain-boundary sliding, accommodated by oxygen grain-boundary diffusion, governed densification.

Similar content being viewed by others

References

J.R. Groza, J.D. Curtis, M. Krämer: Field-assisted sintering of nanocrystalline titanium nitride. J. Am. Ceram. Soc. 83, 1281 2000

Z. Shen, M. Johnsson, Z. Zhao, M. Nygren: Spark plasma sintering of alumina. J. Am. Ceram. Soc. 85, 1921 2002

B.-N. Kim, K. Hiraga, K. Morita, H. Yoshida: Spark plasma sintering of transparent alumina. Scr. Mater. 57, 607 2007

M. Suganuma, Y. Kitagawa, S. Wada, N. Murayama: Pulsed electric current sintering of silicon nitride. J. Am. Ceram. Soc. 86, 387 2003

G. Bernard-Granger, C. Guizard: Spark plasma sintering of a commercially available granulated zirconia powder: I. Sintering path and hypotheses about the mechanism(s) controlling densification. Acta Mater. 55, 3493 2007

Y. Bangchao, J. Jiawen, Z. Yican: Spark-plasma sintering the 8-mol% yttria-stabilized zirconia electrolyte. J. Mater. Sci. Lett. 39, 6863 2004

T. Yamamoto, H. Kitaura, Y. Kodera, T. Ishii, M. Ohyanagi, Z.A. Munir: Consolidation of nanostructured β-SiC by spark plasma sintering. J. Am. Ceram. Soc. 87, 1436 2004

N. Frage, S. Cohen, S. Meir, S. Kalabukhov, M.P. Dariel: Spark plasma sintering (SPS) of transparent magnesium–aluminate spinel. J. Mater. Sci. 42, 3273 2007

K. Morita, B-N. Kim, K. Hiraga, H. Yoshida: Fabrication of transparent MgAl2O4 spinel polycrystal by spark plasma sintering processing. Scr. Mater. 58, 1114 2008

R. Chaim, R. Marder-Jaeckel, J.Z. Shen: Transparent YAG ceramics by surface softening of nanoparticles in spark plasma sintering. Mater. Sci. Eng., A 429, 74 2006

R. Chaim, M. Margulis: Densification maps for spark plasma sintering of nanocrystalline MgO ceramics. Mater. Sci. Eng., A 407, 180 2005

M. Tokita: Mechanism of spark plasma sintering and its application to ceramics. Nyu Seramikkusu 10, 43 1997

V. Mamedov: Spark plasma sintering as advanced PM sintering method. Powder Metall. 45, 322 2002

J.S. Reed: Principles of Ceramic Processing 2nd ed. John Wiley & Sons Inc. New York 1995 p. 438.

G. Bernard-Granger, C. Guizard, A. Addad: Sintering of an ultra pure α-alumina powder: I. Densification, grain growth and sintering path. J. Mater. Sci. 42, 6316 2007

G. Bernard-Granger, C. Guizard: Apparent activation energy for the densification of a commercially available granulated zirconia powder. J. Am. Ceram. Soc. 90, 1246 2007

G. Bernard-Granger, L. San-Miguel, C. Guizard: Sintering behavior and optical properties of yttria. J. Am. Ceram. Soc. 90, 2698 2007

R.J. Brook, E. Gilbert, D. Hind, J.M. Vieira: Sintering—Theory and Practice edited by D. Kolar, S. Pejovnik, and M.M. Ristic Elsevier Amsterdam 1982 p. 585

R.L. Coble: Diffusion models for hot pressing with surface energy and pressure effects as driving forces. J. Appl. Phys. 41, 4798 1970

D. McLean, K.F. Halle: Structural Processes in Creep Spec. Rep. No. 70 The Iron and Steel Institute London 1961 19

A.K. Mukherjee, J.E. Bird, J.E. Dorn: Experimental correlations for high-temperature creep. Trans ASM 62, 155 1969

C. Herring: Diffusional viscosity of a polycrystalline solid. J. Appl. Phys. 21, 437 1950

G. Bernard-Granger, C. Guizard: Sintering of an ultra pure α-alumina powder: II. Mechanical, thermo-mechanical, optical properties and missile dome design. J. Mater. Sci. 2008 (submitted)

M.F. Ashby, R.A. Verrall: Diffusion accommodated flow and superplasticity. Acta Metall. 21, 149 1973

B. Burton: The relationship between dislocation recovery creep and vacancy diffusion creep. Philos. Mag. A 48, L9 1983

J. Weertman: Dislocation climb theory of steady-state creep. Trans. ASM 61, 681 1968

J. Weertman: High temperature creep produced by dislocation motion. John E. Dorn Memorial Symposium Cleveland, OH 1972

K. Messaoudi, A.M. Huntz, B. Lesage: Diffusion and growth mechanisms in Al2O3 scales on kinetic Fe–Cr–Al alloys. Mater. Sci. Eng., A 247, 248 1998

D. Clemens, K. Bongartz, W.J. Quaddakers, H. Nickel, H. Holzbrecher, J.S. Brecker: Determination of lattice and grain-boundary diffusion coefficients in protective alumina scales on high temperature alloys using SEM, TEM and SIMS. Fresenius J. Anal. Chem. 353, 267 1995

A.H. Heuer: Oxygen and aluminium diffusion in α-Al2O3. How much do we really understand? J. Eur. Ceram. Soc. 28, 1495 2008

D. Prot, M. Le Gall, B. Lesage, A.M. Huntz, C. Monty: Self-diffusion in α-Al2O3. IV. Oxygen grain-boundary self-diffusion in undoped and yttria-doped alumina polycrystals. Philos. Mag. A 73, 935 1996

T. Nakagawa, I. Sakaguchi, N. Shibata, K. Matsunaga, T. Mizoguchi, T. Yamamoto: Yttrium do** effect on oxygen grain-boundary diffusion in Al2O3. Acta Mater. 55, 6627 2007

P.C. Panda, R. Raj, P.E.D. Morgan: Superplastic deformation in fine-grained MgO.2Al2O3 spinel. J. Am. Ceram. Soc. 68, 522 1985

K. Morita, K. Hiraga, B-N. Kim, T.S. Suzuki, Y. Sakka: Strain softening and hardening during superplastic-like flow in a fine-grained MgAl2O4 spinel polycrystal. J. Am. Ceram. Soc. 87, 1102 2004

G. Bernard-Granger, N. Benameur, A. Addad, M. Nygren, C. Guizard, S. Deville: Spark plasma sintering of MgAl2O4. J. Am. Ceram. Soc. 2008 (submitted)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bernard-Granger, G., Guizard, C. Densification mechanism involved during spark plasma sintering of a codoped α-alumina material: Part I. Formal sintering analysis. Journal of Materials Research 24, 179–186 (2009). https://doi.org/10.1557/JMR.2009.0025

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2009.0025