Abstract

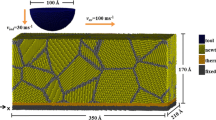

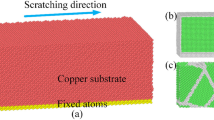

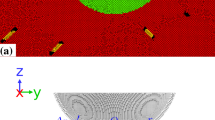

Molecular dynamics simulations are employed to study dislocation movement and wear response of nanocrystalline nickel (Ni). To explore the coefficient of friction values within the range near the Hall–Patch breakdown, samples were prepared with grain sizes ranging from 3.5 to 9.2 nm. Through the simulating a nanoscratching process using a spherical indenter, the concurrent influence of indenter dimensions and grain sizes on the friction coefficient of nanocrystalline Ni is examined. The results indicated that increasing the grain size and indenter dimension in nanocrystalline Ni led to a decrease in the coefficient of friction. Notably, the dimensions of the indenter had a more significant impact on the observed effects compared to the grain size. Also, it is observed that significant dislocation growth occurred during the scratching process when the indenter dimensions are large.

Graphical abstract

Similar content being viewed by others

Data Availability Statement

No Data associated in the manuscript.

References

Y. Zhang, G.J. Tucker, J.R. Trelewicz, Stress-assisted grain growth in nanocrystalline metals: grain boundary mediated mechanisms and stabilization through alloying. Acta Mater. 131, 39–47 (2017)

C.C. Koch, I.A. Ovid’ko, S. Veprek, S. Seal, Structural Nanocrystalline Materials: Fundamentals and Applications (Cambridge University Press, Cambridge, 2007)

H. Van Swygenhoven, J.R. Weertman, Deformation in nanocrystalline metals. Mater. Today 9, 24–31 (2006)

J. Schiøtz, K.W. Jacobsen, A maximum in the strength of nanocrystalline copper. Science 301, 1357–1359 (2003)

Z. Shan, E.A. Stach, J.M.K. Wiezorek et al., Grain boundary-mediated plasticity in nanocrystalline nickel. Science 305, 654–657 (2004)

V. Yamakov, D. Wolf, M. Salazar et al., Length-scale effects in the nucleation of extended dislocations in nanocrystalline Al by molecular-dynamics simulation. Acta Mater. 49, 2713–2722 (2001)

D.A. Hughes, N. Hansen, Exploring the limit of dislocation based plasticity in nanostructured metals. Phys. Rev. Lett. 112, 135504 (2014)

F. Sansoz, K.D. Stevenson, Relationship between hardness and dislocation processes in a nanocrystalline metal at the atomic scale. Phys. Rev. B 83, 224101 (2011)

M. Shafiei, A.T. Alpas, Effect of sliding speed on friction and wear behaviour of nanocrystalline nickel tested in an argon atmosphere. Wear 265, 429–438 (2008)

R. Mishra, B. Basu, R. Balasubramaniam, Effect of grain size on the tribological behavior of nanocrystalline nickel. Mater. Sci. Eng. A 373, 370–373 (2004)

N.P. Wasekar, P. Haridoss, S.K. Seshadri, G. Sundararajan, Sliding wear behavior of nanocrystalline nickel coatings: influence of grain size. Wear 296, 536–546 (2012)

Y.-R. Jeng, P.-C. Tsai, S.-H. Chiang, Effects of grain size and orientation on mechanical and tribological characterizations of nanocrystalline nickel films. Wear 303, 262–268 (2013)

T.J. Rupert, C.A. Schuh, Sliding wear of nanocrystalline Ni–W: structural evolution and the apparent breakdown of Archard scaling. Acta Mater. 58, 4137–4148 (2010)

P. Cavaliere, P. Prete, Tribomechanisms of pure electrodeposited Ni at ultra-fine and nanoscale level. Wear 268, 1490–1503 (2010)

Y. Liu, B. **, D.-J. Li et al., Wear behavior of nanocrystalline structured magnesium alloy induced by surface mechanical attrition treatment. Surf. Coat. Technol. 261, 219–226 (2015)

L. Zhang, Y. Shibuta, X. Huang et al., Grain boundary induced deformation mechanisms in nanocrystalline Al by molecular dynamics simulation: from interatomic potential perspective. Comput. Mater. Sci. 156, 421–433 (2019)

M. Chamani, Three-dimensional multiscale modeling of nanoindentation. J. Mol. Graph. Model. 117, 108324 (2022)

M. Chamani, G.H. Farrahi, M.R. Movahhedy, Molecular dynamics simulation of nanoindentation of nanocrystalline Al/Ni multilayers. Comput. Mater. Sci. 112, 175–184 (2016)

X. Luo, Z. Zhang, L. Chen et al., The near-surface microstructural evolution and the influence of Si particles during nanoscratching of nanocrystalline Al. Appl. Surf. Sci. 573, 151533 (2022)

Z. Wang, T. Sun, H. Zhang et al., The interaction between grain boundary and tool geometry in nanocutting of a bi-crystal copper. Int. J. Extreme Manuf. 1, 045001 (2019)

G.B. Bizana, L.A. Barrales-Mora, 3D grain growth in nanocrystalline Al via molecular dynamics: influence of size, topology and integral mean curvature on grain kinetics. Comput. Mater. Sci. 219, 112009 (2023)

M. Moradi, G.H. Farrahi, M. Chamani, Effect of microstructure on crack behavior in nanocrystalline nickel using molecular dynamics simulation. Theoret. Appl. Fract. Mech. 104, 102390 (2019)

J. French, X.-M. Bai, Molecular dynamics studies of grain boundary mobility and anisotropy in BCC γ-uranium. J. Nucl. Mater. 565, 153744 (2022)

M. Chamani, G.H. Farrahi, Multiscale modeling of nanoindentation and nanoscratching by generalized particle method. J. Mol. Graph. Model. 127, 108675 (2024)

M. Chamani, G.H. Farrahi, M.R. Movahhedy, Friction behavior of nanocrystalline nickel near the Hall–Petch breakdown. Tribol. Int. 107, 18–24 (2017)

Y. Gao, C. Lu, N.N. Huynh et al., Molecular dynamics simulation of effect of indenter shape on nanoscratch of Ni. Wear 267, 1998–2002 (2009)

H.-T. Luu, S.-L. Dang, T.-V. Hoang, N. Gunkelmann, Molecular dynamics simulation of nanoindentation in Al and Fe: on the influence of system characteristics. Appl. Surf. Sci. 551, 149221 (2021)

C.J. Ruestes, A. Stukowski, Y. Tang et al., Atomistic simulation of tantalum nanoindentation: effects of indenter diameter, penetration velocity, and interatomic potentials on defect mechanisms and evolution. Mater. Sci. Eng. A 613, 390–403 (2014)

P.Z. Zhu, Y.Z. Hu, H. Wang, T.B. Ma, Study of effect of indenter shape in nanometric scratching process using molecular dynamics. Mater. Sci. Eng. A 528, 4522–4527 (2011)

R.A. Mirshams, P. Parakala, Nanoindentation of nanocrystalline Ni with geometrically different indenters. Mater. Sci. Eng. A 372, 252–260 (2004)

C. Saringer, M. Tkadletz, M. Kratzer, M.J. Cordill, Direct determination of the area function for nanoindentation experiments. J. Mater. Res. 36, 2154–2165 (2021)

G.J. Tucker, S.M. Foiles, Molecular dynamics simulations of rate-dependent grain growth during the surface indentation of nanocrystalline nickel. Mater. Sci. Eng. A 571, 207–214 (2013)

A. Hasnaoui, P.M. Derlet, H. Van Swygenhoven, Interaction between dislocations and grain boundaries under an indenter—a molecular dynamics simulation. Acta Mater. 52, 2251–2258 (2004)

T. Junge, J.-F. Molinari, Plastic activity in nanoscratch molecular dynamics simulations of pure aluminium. Int. J. Plast. 53, 90–106 (2014)

G.P. Purja Pun, Y. Mishin, Development of an interatomic potential for the Ni–Al system. Phil. Mag. 89, 3245–3267 (2009)

E.T. Lilleodden, J.A. Zimmerman, S.M. Foiles, W.D. Nix, Atomistic simulations of elastic deformation and dislocation nucleation during nanoindentation. J. Mech. Phys. Solids 51, 901–920 (2003)

J.D. Honeycutt, H.C. Andersen, Molecular dynamics study of melting and freezing of small Lennard-Jones clusters. J. Phys. Chem. 91, 4950–4963 (1987)

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995)

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 18, 015012 (2010)

J. Li, J. Guo, H. Luo et al., Study of nanoindentation mechanical response of nanocrystalline structures using molecular dynamics simulations. Appl. Surf. Sci. 364, 190–200 (2016)

J. Li, B. Lu, H. Zhou et al., Molecular dynamics simulation of mechanical properties of nanocrystalline platinum: grain-size and temperature effects. Phys. Lett. A 383, 1922–1928 (2019)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chamani, M. Simultaneous effect of grain size and indenter dimension on the dislocation nucleation and growth in nanoindentation and nanoscratch processes. Eur. Phys. J. Plus 139, 426 (2024). https://doi.org/10.1140/epjp/s13360-024-05251-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-024-05251-7