Abstract

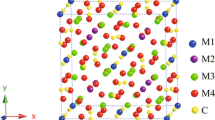

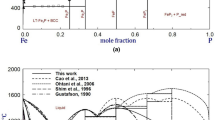

To design and apply liquid Pb as coolant in nuclear reactors, it is important to understand its atomic behaviors with the steel container through molecular dynamics (MD) simulations. A reliable and capable Fe–Pb potential is the key to the MD simulations. In this work, an analytical bond-order potential (BOP) of Fe–Pb has been constructed through the data-fitting of various phases from experiments and first-principles calculations. The newly constructed potential has a better performance in predicting different Fe–Pb phases than the Fe–Pb potentials already published in the literature. Molecular dynamics simulations based on this BOP have been conducted to study the effect of Pb on bulk and grain boundary of BCC and FCC iron. For bulk iron, it is found that of the addition of Pb decreases the elastic constants, elastic moduli, and ductility of BCC Fe more significant than that of FCC Fe. The calculations of two typical tilt symmetrical grain boundaries of Fe and Fe96Pb4 indicate that the appearance of Pb would cause a more considerable brittleness for BCC Fe than that for FCC Fe. The obtained results are in good agreement with similar experimental observations in the literature, which not only provides a strong support to the reliability of newly constructed Fe–Pb potential, but sheds lights on the understanding of mechanical properties of Fe–Pb system.

Graphical abstract

Similar content being viewed by others

Data Availability Statement

This manuscript has no associated data or the data will not be deposited. [Authors’ comment: This work is purely theoretical, having no associated experimental or observational data].

References

V. Sobolev, Thermophysical properties of lead and lead–bismuth eutectic. J. Nucl. Mater. 362(2–3), 235–247 (2007). https://doi.org/10.1016/j.jnucmat.2007.01.144

E.P. Loewen, A.T. Tokuhiro, Status of research and development of the lead-alloy-cooled fast reactor. J. Nucl. Sci. Technol. 40(8), 614–627 (2003). https://doi.org/10.1080/18811248.2003.9715398

L.K. Mansur, A.F. Rowcliffe, R.K. Nanstad, S.J. Zinkle, W.R. Corwin, R.E. Stoller, Materials needs for fusion, generation IV fission reactors and spallation neutron sources—similarities and differences. J. Nucl. Mater. (2004). https://doi.org/10.1016/j.jnucmat.2004.04.016

N. Baluc, Materials for fusion power reactors. Plasma Phys. Controlled Fusion 48(12B), B165–B177 (2006). https://doi.org/10.1088/0741-3335/48/12b/s16

E. Ricci, C. Tomasi, R. Novakovic, S. Amore, D. Giuranno, Wetting property of liquid Pb on different steel candidates as structural materials for the Generation IV nuclear reactors. High Temp. High Pressures 50(1), 49–61 (2021). https://doi.org/10.32908/hthp.v50.871

H.A. Abderrahim, P. Kupschus, E. Malambu, P. Benoit, D. Vandeplassche, MYRRHA: a multipurpose accelerator driven system for research & development. Nucl. Instrum. Methods A 463, 487–494 (2001). https://doi.org/10.1016/S0168-9002(01)00164-4

B. Xu, P. Li, C. Chan, Application of phase change materials for thermal energy storage in concentrated solar thermal power plants: a review to recent developments. Appl. Energy 160, 286–307 (2015). https://doi.org/10.1016/j.apenergy.2015.09.016

T. Auger, G. Lorang, Liquid metal embrittlement susceptibility of T91 steel by lead? Bismuth. Scr. Mater. 52(12), 1323–1328 (2005). https://doi.org/10.1016/j.scriptamat.2005.02.027

R.L. Klueh, A.T. Nelson, Ferritic/martensitic steels for next-generation reactors. J. Nucl. Mater. 371(1–3), 37–52 (2007). https://doi.org/10.1016/j.jnucmat.2007.05.005

C. Keller, M.M. Margulies, Z. Hadjem-Hamouche, I. Guillot, Influence of the temperature on the tensile behaviour of a modified 9Cr–1Mo T91 martensitic steel. Mater. Sci. Eng. A 527(24–25), 6758–6764 (2010). https://doi.org/10.1016/j.msea.2010.07.021

G. Kalinin, V. Barabash, A. Cardella, J. Dietz, K. Ioki, R. Matera, R.T. Santoro, R. Tivey, Assessment and selection of materials for ITER in-vessel components. J. Nucl. Mater. 283–287, 10–19 (2000). https://doi.org/10.1016/S0022-3115(00)00305-6

O. Yeliseyeva, V. Tsisar, G. Benamati, Influence of temperature on the interaction mode of T91 and AISI 316L steels with Pb–Bi melt saturated by oxygen. Corros. Sci. 50(6), 1672–1683 (2008). https://doi.org/10.1016/j.corsci.2008.02.006

J. Zhang, F. Guyot, Experimental study of the bcc-fcc phase transformations in the Fe-rich system Fe-Si at high pressures. Phys Chem Minerals 26, 419–424 (1999). https://doi.org/10.1007/s002690050203

C. Engin, H.M. Urbassek, Molecular-dynamics investigation of the fcc→bcc phase transformation in Fe. Comput. Mater. Sci. 41(3), 297–304 (2008). https://doi.org/10.1016/j.commatsci.2007.04.019

L.T. Belkacemi, E. Meslin, B. Décamps, B. Radiguet, J. Henry, Radiation-induced bcc-fcc phase transformation in a Fe 3%Ni alloy. Acta Mater. 161, 61–72 (2018). https://doi.org/10.1016/j.actamat.2018.08.031

Z. Shi, Y. Shen, D. Peng, Y. Chuan Jiang, H. Gong, Fundamental effect of lead on mechanical properties of iron from a constructed iron-lead potential. Comput. Mater. Sci. (2022). https://doi.org/10.1016/j.commatsci.2022.111587

Y.C. Jiang, J. Zhao, L. Sun, H.R. Gong, X. Gong, Effects of alloying elements on cohesion and brittleness of grain boundary of iron. Mater. Chem. Phys. (2022). https://doi.org/10.1016/j.matchemphys.2021.125291

X. Gong, H. Chen, F. Zhang, W. Zhu, H. Ma, B. Pang, Y. Yin, Degradation of tensile mechanical properties of two AlxCoCrFeNi (x=0.3 and 0.4) high-entropy alloys exposed to liquid lead-bismuth eutectic at 350 and 500°C. J. Nucl. Mater. (2022). https://doi.org/10.1016/j.jnucmat.2021.153364

T. Liu, J. Hui, B. Zhang, X. He, M. Liu, J. Qiu, W. Liu, Corrosion mechanism of lead-bismuth eutectic at grain boundary in ferritic steels and the effect of alloying elements: a first-principles study. J. Nucl. Mater. (2022). https://doi.org/10.1016/j.jnucmat.2022.153915

X.W. Zhou, R.A. Johnson, H.N.G. Wadley, Misfit-energy-increasing dislocations in vapor-deposited CoFe/NiFe multilayers. Phys. Rev. B (2004). https://doi.org/10.1103/PhysRevB.69.144113

A.R. Alian, S.A. Meguid, S.I. Kundalwal, Unraveling the influence of grain boundaries on the mechanical properties of polycrystalline carbon nanotubes. Carbon 125, 180–188 (2017). https://doi.org/10.1016/j.carbon.2017.09.056

S. Mishra, N. Luhadiya, S.I. Kundalwal, Atomistic insights into the H2 adsorption and desorption behavior of novel Li-functionalized polycrystalline CNTs. Carbon 207, 23–35 (2023). https://doi.org/10.1016/j.carbon.2023.03.002

S. Mishra, P.P. Maware, V. Choyal, S.I. Kundalwal, Atomistic insights into the fracture mechanisms of Stone–Wales-defected CNTs under transversely isotropic loading. Eur. Phys. J. Plus (2023). https://doi.org/10.1140/epjp/s13360-023-04104-z

A. Maulana, Z. Su’ud, K.D. Hermawan, Khairurrijal, Simulation study of steels corrosion phenomenon in liquid lead–bismuth cooled reactors using molecular dynamics methods. Prog. Nucl. Energy 50(2–6), 616–620 (2008). https://doi.org/10.1016/j.pnucene.2007.11.087

D.G. Pettifor, New many-body potential for the bond order. Phys. Rev. Lett. 63(22), 2480–2483 (1989). https://doi.org/10.1103/PhysRevLett.63.2480

D.G. Pettifor, I.I. Oleinik, Analytic bond-order potentials beyond Tersoff–Brenner. I. Theory. Phys. Rev. B 59(13), 8487–8499 (1999). https://doi.org/10.1103/PhysRevB.59.8487

D.G. Pettifor, I.I. Oleinik, Bounded analytic bond-order potentials for s and p bonds. Phys. Rev. Lett. 84(18), 4127–4127 (2000). https://doi.org/10.1016/j.msea.2003.09.001

D.G. Pettifor, I.I. Oleinik, Analytic bond-order potential for open and close-packed phases. Phys. Rev. B (2002). https://doi.org/10.1103/PhysRevB.65.172103

Z.B. Liang, Y.C. Jiang, X. Gong, H.R. Gong, Atomistic modelling of the immiscible Fe-Bi system from a constructed bond order potential. J. Phys. Condens. Matter (2022). https://doi.org/10.1088/1361-648X/ac2e8e

X.W. Zhou, D.K. Ward, M.E. Foster, An analytical bond-order potential for the aluminum copper binary system. J. Alloys Compd. 680, 752–767 (2016). https://doi.org/10.1016/j.jallcom.2016.04.055

D.K. Ward, X.W. Zhou, B.M. Wong, F.P. Doty, J.A. Zimmerman, Analytical bond-order potential for the Cd–Zn–Te ternary system. Phys. Rev. B (2012). https://doi.org/10.1103/PhysRevB.86.245203

D. Pettifor, M. Finnis, D. Nguyen-Manh, D. Murdick, X. Zhou, H. Wadley, Analytic bond-order potentials for multicomponent systems. Mater. Sci. Eng. A 365(1–2), 2–13 (2004)

L. Goodwin, A.J. Skinner, D.G. Pettifor, Generating transferable tight-binding parameters: application to silicon. Europhys. Lett. 9(7), 701 (1989)

D.K. Ward, X.W. Zhou, B.M. Wong, F.P. Doty, J.A. Zimmerman, Analytical bond-order potential for the cadmium telluride binary system. Phys. Rev. B (2012). https://doi.org/10.1103/PhysRevB.85.115206

G. Kresse, J. Hafner, Ab initio molecular dynamics for open-shell transition metals. Phys. Rev. B Condens. Matter 48(17), 13115–13118 (1993). https://doi.org/10.1103/physrevb.48.13115

G. Kresse, D. Joubert, From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59(3), 1758–1775 (1999). https://doi.org/10.1103/PhysRevB.59.1758

L.C. Liu, H.R. Gong, S.F. Zhou, X. Gong, Adsorption, diffusion, and permeation of hydrogen at PdCu surfaces. J. Membr. Sci. 588, 117206 (2019). https://doi.org/10.1016/j.memsci.2019.117206

J.P. Perdew, K. Burke, M. Ernzerhof, Generalized gradient approximation made simple. Phys. Rev. Lett. 77(18), 3865–3868 (1996). https://doi.org/10.1103/PhysRevLett.77.3865

L. Sun, C.Y. Wu, J.C. Han, H.R. Gong, M.L. Chang, D.C. Chen, Band structure and thermoelectric performances of antimony under trigonal transformation. J. Appl. Phys. 125(14), 145102.1-145102.10 (2019). https://doi.org/10.1063/1.5088868

J.C. Han, C.Y. Wu, L. Sun, H.R. Gong, X. Gong, Influence of trigonal deformation on band structure and Seebeck coefficient of tellurium. J. Phys. Chem. Solids 135, 109114 (2019). https://doi.org/10.1016/j.jpcs.2019.109114

M. Methfessel, A.T. Paxton, High-precision sampling for Brillouin-zone integration in metals. Phys. Rev. B Condens. Matter 40(6), 3616–3621 (1989). https://doi.org/10.1103/physrevb.40.3616

P.E. Blochl, Projector augmented-wave method. Phys. Rev. B Condens. Matter 50(24), 17953–17979 (1994). https://doi.org/10.1103/physrevb.50.17953

D.E. Gray, H. Wise, American Institute of Physics Handbook (McGraw-Hill, New York, 1972)

Y.K. Vohra, A.L. Ruoff, Static compression of metals Mo, Pb, and Pt to 272 GPa: comparison with shock data. Phys. Rev. B Condens. Matter 42(13), 8651–8654 (1990). https://doi.org/10.1103/physrevb.42.8651

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117(1), 1–19 (1995). https://doi.org/10.1006/jcph.1995.1039

T. Gao, H. Song, B. Wang, Y. Gao, Y. Liu, Q. **e, Q. Chen, Q. **ao, Y. Liang, Molecular dynamics simulations of tensile response for FeNiCrCoCu high-entropy alloy with voids. Int. J. Mech. Sci. (2023). https://doi.org/10.1016/j.ijmecsci.2022.107800

W. Liu, Y. Wei, F. Zhang, J. Zhou, Tensile behavior of ferritic/austenitic iron with a bimodal structure: an atomistic study. Mater. Today Commun. (2022). https://doi.org/10.1016/j.mtcomm.2022.103883

J. Xu, Y. Jiang, L. Yang, J. Li, Assessment of the CSL and SU models for bcc-Fe grain boundaries from first principles. Comput. Mater. Sci. 122, 22–29 (2016). https://doi.org/10.1016/j.commatsci.2016.05.009

J.A.C. Lilly, J.R. McDowell, High-field conduction in films of mylar and teflon. J. Appl. Phys. 39, 141–147 (1968). https://doi.org/10.1063/1.1655720

J. Zarestky, C. Stassis, Lattice dynamics of γ-Fe. Phys. Rev. B 35, 4500 (1987). https://doi.org/10.1103/PhysRevB.35.4500

R.E. Newnham, Properties of Materials: Anisotropy, Symmetry, Structure (Oxford University Press, 2005)

W.R. Warke, K.L. Johnson, N.N. Breyer, Corrosion by Liquid Metals (Springer, Boston, 1970)

E. Nunes, E.C. Passamani, C. Larica, J.C.C. Freitas, A.Y. Takeuchi, E. Baggio-Saitovitch, A.C. Doriguetto, A.A.R. Fernandes, Extended solubility in non-equilibrium Pb/Fe system. Mater. Sci. Eng. A 390(1–2), 13–18 (2005). https://doi.org/10.1016/j.msea.2004.05.032

E. Nunes, E. Passamani, C. Larica, J. Freitas, A. Takeuchi, Solubility study of Fe0.95Pb0.05 alloy prepared by high energy ball milling. J. Alloys Compd. 345, 116–122 (2002). https://doi.org/10.1016/S0925-8388(02)00410-3

G.A. Dorofeev, E.P. Elsukov, Mechanical alloying of the Fe–Pb system immiscible in the equilibrium state. Phys. Met. Metallogr. 103(6), 593–599 (2007). https://doi.org/10.1134/s0031918x07060087

D. Gorse, T. Auger, J.-B. Vogt, I. Serre, A. Weisenburger, A. Gessi, P. Agostini, C. Fazio, A. Hojna, F.D. Gabriele, J.V.D. Bosch, G. Coen, A. Almazouzi, M. Serrano, Influence of liquid lead and lead–bismuth eutectic on tensile, fatigue and creep properties of ferritic/martensitic and austenitic steels for transmutation systems. J. Nucl. Mater. 415(3), 284–292 (2011). https://doi.org/10.1016/j.jnucmat.2011.04.047

F. Mouhat, F.-X. Coudert, Necessary and sufficient elastic stability conditions in various crystal systems. Phys. Rev. B (2014). https://doi.org/10.1103/PhysRevB.90.224104

G. Coen, J.V.D. Bosch, A. Almazouzi, J. Degrieck, Investigation of the effect of lead–bismuth eutectic on the fracture properties of T91 and 316L. J. Nucl. Mater. 398(1–3), 122–128 (2010). https://doi.org/10.1016/j.jnucmat.2009.10.021

O. Milton, The Materials Science of Thin Films: Deposition and Structure, World Scientific (2006)

K. Chen, M. Bielawski, Interfacial fracture toughness of transition metal nitrides. Surf. Coat. Technol. 203(3), 598–601 (2008). https://doi.org/10.1016/j.surfcoat.2008.05.040

J.F. Nye, Physical Properties of Crystals. Clarencon (1985)

C. He, M. Cheng, M. Zhang, W.X. Zhang, Interfacial Stability and Electronic Properties of Ag/M (M = Ni, Cu, W, and Pd) and Cu/Cr Interfaces. J. Phys. Chem. C 122(31), 17928–17935 (2018). https://doi.org/10.1021/acs.jpcc.8b05920

H. Zheng, X.-G. Li, R. Tran, C. Chen, M. Horton, D. Winston, K.A. Persson, S.P. Ong, Grain boundary properties of elemental metals. Acta Mater. 186, 40–49 (2020). https://doi.org/10.1016/j.actamat.2019.12.030

R.J. Kurtz, H.L. Heinisch, The effects of grain boundary structure on binding of He in Fe. J. Nucl. Mater. 329–333, 1199–1203 (2004). https://doi.org/10.1016/j.jnucmat.2004.04.262

Y.A. Du, L. Ismer, J. Rogal, T. Hickel, J. Neugebauer, R. Drautz, First-principles study on the interaction of H interstitials with grain boundaries inα- andγ-Fe. Phys. Rev. B (2011). https://doi.org/10.1103/PhysRevB.84.144121

H. Beladi, G.S. Rohrer, The relative grain boundary area and energy distributions in a ferritic steel determined from three-dimensional electron backscatter diffraction maps. Acta Mater. 61(4), 1404–1412 (2013). https://doi.org/10.1016/j.actamat.2012.11.017

D. Scheiber, R. Pippan, P. Puschnig, L. Romaner, Ab initiocalculations of grain boundaries in bcc metals. Modell. Simul. Mater. Sci. Eng. (2016). https://doi.org/10.1088/0965-0393/24/3/035013

T. Hickel, A. Dick, B. Grabowski, F. Körmann, J. Neugebauer, Steel design from fully parameter-free Ab initio computer simulations. Mater. Technol. 1, 4–8 (2009). https://doi.org/10.2374/SRI08SP109

A. Legris, G. Nicaise, J.-B. Vogt, J. Foct, D. Gorse, D. Vancon, Embrittlement of a martensitic steel by liquid lead. Scr. Mater. 43, 997–1001 (2000). https://doi.org/10.1016/s1359-6462(00)00523-6

I.P. Serre, J.-B. Vogt, Mechanical behavior in liquid lead of Al2O3 coated 15–15Ti steel and an alumina-forming austenitic steel designed to mitigate their corrosion. Eng. Fail. Anal. (2022). https://doi.org/10.1016/j.engfailanal.2022.106443

Z. Hamouche-Hadjem, T. Auger, I. Guillot, D. Gorse, Susceptibility to LME of 316L and T91 steels by LBE: effect of strain rate. J. Nucl. Mater. 376(3), 317–321 (2008). https://doi.org/10.1016/j.jnucmat.2008.02.031

E. Stergar, S.G. Eremin, S. Gavrilov, M. Lambrecht, O. Makarov, V. Iakovlev, Influence of LBE long term exposure and simultaneous fast neutron irradiation on the mechanical properties of T91 and 316L. J. Nucl. Mater. 473, 28–34 (2016). https://doi.org/10.1016/j.jnucmat.2016.02.008

Acknowledgements

This work is financially supported by Natural Science Foundation of Hunan Province (Grant No. 2022JJ30719). We are grateful for resources from the High Performance Computing Center of Central South University.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Peng, D., Hu, J., Jiang, Y. et al. The influence of lead on mechanical properties of BCC and FCC iron from a constructed bond-order potential. Eur. Phys. J. Plus 138, 1082 (2023). https://doi.org/10.1140/epjp/s13360-023-04668-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-023-04668-w