Abstract

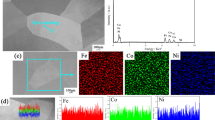

The corrosion properties inherent in oxide coatings formed on VT1-0 and VT5 grade titanium alloys affected by fast pulsed discharges under the process of microarc oxidation (MAO) have been studied both after sealing the coatings with polymers and with no sealing. The MAO coatings were formed in a pulsed mode, the duration of the anode current pulse amounting to 250 ± 25 μs, the duration of cathode current pulse being of 5 ± 0.5 ms, the pause between the anode and cathode current pulses amounting to 250 ± 25 μs, and the repetition rate of the anode and cathode pulses being of 50 ± 0.5 Hz. Alkaline solutions were used as electrolytes. Fluoroplastic and epoxy resin solutions were used to seal the oxide coatings. The obtained MAO coatings had 4.4–7.5% porosity in the case of the VT1-0 grade alloy and 5.4–12.1% porosity in the case of the VT5 grade alloy. The average pore diameter in the oxide coatings ranged from 0.1 to 0.5 μm. The XRD phase analysis has shown the fact that, in the composition of oxide coatings, there are anatase and rutile modifications of titanium dioxide. The corrosion testing performed using a 24% sulfuric acid solution at 40 and 75°C has shown that both oxide and oxide-polymeric coatings formed on the VT1-0 grade alloy are more corrosion resistant than similar coatings formed on the VT5 grade alloy. All the types of coatings formed on the VT1-0 alloy are corrosion-resistant at a testing temperature of 40°C. The sealing of MAO coatings with the use of polymeric materials improves their corrosion-resistant properties.

Similar content being viewed by others

REFERENCES

Santecchia, E., Zalnezhad, E., Hamouda, A.M.S., Musharavati, F., Cabibbo, M., and Spigarelli, S., Wear resistance investigation of titanium nitride-based coatings, Ceram. Int., 2015, vol. 41, no. 9 (A), pp. 10349–10379. https://doi.org/10.1016/j.ceramint.2015.04.152

Van Hove, R.P., Sierevelt, I.N., Van Royen, B.J., and Nolte, P.A., Titanium-nitride coating of orthopaedic implants: A review of the literature, BioMed Res. Int., 2015, vol. 2015, art. ID 485975. https://doi.org/10.1155/2015/485975

Shankar, M.P., Sokkalingam, R., Sivaprasad, K., and Veerappan, Muthupandi, Effect of electrolyte on micro arc oxidation coating of Al-2014 alloy, Adv. Mater. Res., 2018, vol. 1148, pp. 159–164. https://doi.org/10.4028/www.scientific.net/AMR.1148.159

**, J., Li, X.-H., Wu, J.-W., and Lou, B.-Y., Improving tribological and corrosion resistance of Ti6Al4V alloy by hybrid microarc oxidation. Enameling treatments, Rare Met., 2018, vol. 37, pp. 26–34. https://doi.org/10.1007/s12598-015-0644-9

Ono, S., Moronuki, Sh., Mori, Y., Koshi, A., Liao, J., and Asoh, H., Effect of electrolyte concentration on the structure and corrosion resistance of anodic films formed on magnesium through plasma electrolytic oxidation, Electrochim. Acta, 2017, vol. 240, pp. 415–423. https://doi.org/10.1016/j.electacta.2017.04.110

Simchen, F., Sieber, M., Kopp, A., and Lampke, T., Introduction to plasma electrolytic oxidation—an overview of the process and applications, Coatings, 2020, vol. 10, no. 7, art. ID 628. https://doi.org/10.3390/coatings10070628

Sakhnenko, N.D., Ved, M.V., and Karakurkchi, A.V., Effect of do** metals on the structure of PEO coatings on titanium, Int. J. Chem. Eng., 2018, vol. 2018, art. ID 4608485. https://doi.org/10.1155/2018/4608485

Krit, B.L., Ludin, V.B., Morozova, N.V., and Apel-feld, A.V., Microarc oxidation of carbon-graphite materials (review), Surf. Eng. Appl. Electrochem., 2018, vol. 54, no. 3, pp. 227–246. https://doi.org/10.3103/S1068375518030080

Zhou, T., Qin, Z.-B., Luo, Q., Zhang, Q., Shen, B., Hu, W.-B., and Liu, L., Synthetic effects of frequency and duty ratio on growth characteristics, energy consumption and corrosion properties of microarc oxidized coating formed on Ti6Al4V, Acta Metall. Sin., 2018, vol. 31, pp. 1109–1120. https://doi.org/10.1007/s40195-018-0748-y

Mamaev, A.I., Dolgova, Yu.N., Beletskaya, E.Yu., et al., Synthesis of nanostructured nonmetallic inorganic coatings at high energy localization in interfacial nanolayers, Russ. Phys. J., 2021, vol. 63, no. 9, pp. 1605–1614. https://doi.org/10.1007/s11182-021-02212-w

Zhou, T., Ding, Y., Luo, Q., Qin, Z., Zhang, Q., Shen, B., Hu, W., and Liu, L., The effects of sodium tungstate on the characteristics of microarc oxidation coating on Ti6Al4V, J. Mater. Eng. Perform., 2018, vol. 27, pp. 5489–5499. https://doi.org/10.1007/s11665-018-3613-2

Qi, X., Shang, H., Ma, B., Zhang, R., Guo, L., and Su, B., Microstructure and wear properties of micro arc oxidation ceramic coatings, Materials (Basel), 2020, vol. 13, no. 4, art. ID 970. https://doi.org/10.3390/ma13040970

Ramazanova, Zh.M., Kirgizbayeva, K.Zh., Akhmedyanov, A.U., Jaxymbetova, M.A., Yergaliyev, D., Zhakupova, A., and Abdirashev, O., Influence of the process of microplasma treatment in electrolyte solutions on the oxide coating properties, Int. J. Mech. Eng. Technol., 2018, vol. 9, no. 12, pp. 709–721.

Shtefan, V.V. and Smirnova, A.Yu., Oxidation of titanium in Zr- and Mo-containing solutions, Prot. Met. Phys. Chem. Surf., 2017, vol. 53, pp. 322–328. https://doi.org/10.1134/S2070205117020241

Karabudak, F., Yeşildal, R., Şűkűroğlu, E.E., Şűkűroğlu, S., Zamanlou, H., Dikbaş, N., Bayındır, F., Şen, S., and Totik, Y., An investigation of corrosion resistance and antibacterial sensitivity properties of nano-Ag-doped TiO2 coating and TiO2 coating grown on NiTi alloy with the microarc oxidation process, Arabian J. Sci. Eng., 2017, vol. 42, pp. 2329–2339. https://doi.org/10.1007/s13369-017-2463-9

Ram Kumar, V. and Muthupandi, V., Effect of electrolyte in microarc oxidation on providing corrosion resistance to inhomogeneous microstructure in ZM21 magnesium alloy, Trans. Indian Inst. Met., 2019, vol. 72, pp. 1617–1620. https://doi.org/10.1007/s12666-019-01707-y

Aliasghari, S., Nemcova, A., Cizek, J., Gholinia, A., Skeldon, P., and Thompson, G.E., Effects of reagent purity on plasma electrolytic oxidation of titanium in an aluminate-phosphate electrolyte, Int. J. Surf. Eng. Coat., 2016, vol. 94, pp. 32–42. https://doi.org/10.1080/00202967.2015.1121692

Koshuro, V.A., Fomina, M.A., Rodionov, I.V., and Fomin, A.A., Nanoporous structure of coatings formed by thermal spraying of aluminum oxide with further microarc oxidation on titanium alloy VT6 implants, Biomed. Eng., 2016, vol. 50, pp. 54–57. https://doi.org/10.1007/s10527-016-9586-2

Kazek-Kesik, A., Jaworska, J., Krok-Borkowicz, M., Głoda-Cepa, M., Pastusiak, M., Brzychczy-Włoch, M., Pamuła, El., Kotarba, A., and Simka, W., Hybrid oxidepolymer layer formed on the Ti–15Mo alloy surface enhancing antibacterial and osseointegration functions, Surf. Coat. Technol., 2016, vol. 302, pp. 158–165. https://doi.org/10.1016/j.surfcoat.2016.05.073

Mamaev, A.I., Mamaeva, V.A., Kalita, V.I., Komlev, D.I., Radyuk, A.A., Iyannikov, A.Yu., Mikhaylova, A.B., Baikin, A.S., Sevostyanov, M.A., and Amelchenko, N.A., Shear strength of the cylindrical titanium implant–plastic system, Inorg. Mater.: Appl. Res., 2018, vol. 9, pp. 855–860. https://doi.org/10.1134/S2075113318050209

Sieber, M., Simchen, F., Morgenstern, R., Scharf, I., and Lampke, T., Plasma electrolytic oxidation of high-strength aluminium alloys-substrate effect on wear and corrosion performance, Metals, 2018, vol. 8, no. 5, pp. 351–356. https://doi.org/10.3390/met8050356

Suminov, I.V., Epel’fel’d, A.V., Lyudin, B.V., et al., Mikrodugovoe oksidirovanie: Teoriya, tekhnologiya, oborudovanie (Microarc Oxidation: Theory, Technology, and Equipment), Moscow: Ekomet, 2005.

Saltykov, S.A., Stereometricheskaya metallografiya (Stereometric Metallography), Moscow: Metallurgiya, 1970.

Ramazanova, Zh.M. and Zamalitdinova, M.G., Study of the properties of oxide coatings formed on titanium by plasma electrolytic oxidation method, Eurasian Chem.-Technol. J., 2020, no. 22, pp. 51–58.

Ramazanova, Zh., Zamalitdinova, M., Kozlovskiy, A., Butyagin, P., and Arbuzova, S., Synthesis and properties of coatings obtained by plasma electrolytic oxidation of titanium alloys in alkaline solutions, J. Adv. Res. Dyn. Control Syst., 2020, vol. 12, no. 6, pp. 858–865. https://doi.org/10.5373/JARDCS/V12SP6/SP20201103

Ramazanova, Zh.M. and Zamalitdinova, M.G., Physical and mechanical properties investigation of oxide coatings on titanium, Kompl. Ispol’z. Mineral. Syr’ya, 2019, vol. 2, pp. 34–41.

Ramazanova, Zh.M. and Zamalitdinova, M.G., Study of properties of oxide coatings on titanium VT5 alloy, Sovr. Naukoem. Tekhnol., 2019, no. 3, pp. 239–243.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by O. Polyakov

Rights and permissions

About this article

Cite this article

Ramazanova, Z.M., Zamalitdinova, M.G., Kirgizbayeva, K.Z. et al. Protective Properties of Coatings Obtained via Microarc Oxidation in Alkaline Electrolyte Solutions. Inorg. Mater. Appl. Res. 13, 1414–1421 (2022). https://doi.org/10.1134/S2075113322050379

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113322050379