Abstract

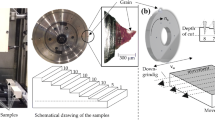

Specimens made of glass-reinforced plastic with a thickness of 2.2 mm, made on a melt binder EDT-69N, were scratched using a laboratory sclerometer at various loads on the indenter; scratches were applied both to the front surface of the specimens in the fractional and transverse directions and to thin sections made in two mutually perpendicular planes along the thickness of the samples. It was found that, with an increase in the load on the indenter, the force of resistance to scratching also increased, while the width of the formed groove increased. The force of resistance to scratching in the transverse direction relative to the orientation of the fibers was 30–45% higher than the force of resistance to scratching when the indenter moves along the filler fibers, while the groove channel had torn edges due to the destruction of the transverse fibers of the fiberglass. Microscopic studies were carried out on grooves applied to the front surface of the samples and in the plane of transverse sections, where the destruction of filler fibers oriented parallel and perpendicular to the plane of the section was investigated. The microhardness of the matrix of the samples was studied on transverse thin sections in the core and subsurface zones in two mutually perpendicular planes, conventionally called lateral and end surfaces. It was found that the value of the microhardness of the core zone of the matrix exceeded the values of the microhardness of the matrix in the subsurface zones of the samples by 13–14 MPa; no difference in the values of the microhardness of the matrix in mutually perpendicular planes was noted. The roughness of the front and back surfaces of the samples was studied and it was shown that the roughness of the front surface of the sample was two times lower than the roughness of its back side.

Similar content being viewed by others

REFERENCES

Raskutin, A.E., Development strategy of polymer composite materials, Aviats. Mater. Tekhnol., 2017, no. S, pp. 344–348. https://doi.org/10.18577/2071-9140-2017-0-S-344-348

Kablov, E.N., Russia on the intellectual resources market, Ekspert, 2015, no. 28 (951), pp. 48–51.

Grashchenkov, D.V., Strategy of development of non-metallic materials, metal composite materials and heat-shielding, Aviats. Mater. Tekhnol., 2017, no. S, pp. 264–271. https://doi.org/10.18577/2071-9140-2017-0-S-264-271

Raskutin, A.E., Russian polymer composite materials of new generation, their exploitation and implementation in advanced developed constructions, Aviats. Mater. Tekhnol., 2017, no. S, pp. 349–367. https://doi.org/10.18577/2071-9140-2017-0-S-349-367

Kablov, E.N., Composites: Today and tomorrow, Met. Evraz., 2015, no. 1, pp. 36–39.

Mostovoi, A.S. and Ledenev, A.N., Modification of epoxy polymers by nanosized silicon, Fiz. Khim. Obrab. Mater., 2017, no. 4, pp. 61–66.

Aristov, V.M. and Aristova, E.P., The influence of structural inhomogeneity on the physical properties of partially crystalline polymers, Int. Polym. Sci. Technol., 2017, vol. 44, no. 4, pp. 21–24. https://doi.org/10.1177/0307174X1704400404

Platonov, A.A., Kogan, D.I., and Dushin, M.I., Manufacturing of three-dimensional PCMs by impregnation with a film binder, Plast. Massy, 2013, no. 6, pp. 56–61.

Lavrov, N.A., Kiemov, Sh.N., and Kryzhanovskii, V.K., Properties of filled epoxy polymers, Plast. Massy, 2019, nos. 1–2, pp. 37–39.

Vul’f, B.K. and Romadin, K.P., Aviatsionnoe materialovedenie (Aviation Materials Science), Moscow: Mashinostroenie, 1967.

Tager, A.A., Fiziko-khimiya polimerov (Physicochemistry of Polymers), Moscow: Nauchn. Mir, 2007.

Veshkin, E.A., Postnov, V.I., and Semenychev, V.V., Evaluating the microhardness of samples based on binder VST-1210 cured under various conditions as a method of testing, Inorg. Mater.: Appl. Res., 2019, vol. 10, pp. 127–130. https://doi.org/10.1134/S2075113319010386

GOST (State Standard) 9450-76: Measuring Microhardness by Indentation of Diamond Tips, 1976.

Kuritsyna, A.D., Application of the microhardness method to determine some properties of polymer materials, in Metody ispytaniya na mikrotverdost’ (Microhardness Testing Methods), Moscow: Nauka, 1965, pp. 255–260.

Veshkin, E.A., Postnov, V.I., Semenychev, V.V., and Krasheninnikova, E.V., Anisotropic properties of cured binders, Polym. Sci., Ser. D, 2019, vol. 12, pp. 5–8. https://doi.org/10.1134/S1995421219010234

Veshkin, E.A., Postnov, V.I., Semenychev, V.V., and Barannikov, A.A., Anisotropy of properties in the high section of samples from glass plastics, formed by press and autoclaude, Kompozity Nanostrukt., 2019, vol. 11, no. 2 (42), pp. 51–58.

Veshkin, E.A., Semenychev, V.V., Postnov, V.I., and Krasheninnikova, E.V., Research of the geometric section for sclerometric furnish sections obtained on the cured binding EDT-69N at different load levels for inductor, Tr. VIAM, 2020, no. 3 (87), pp. 74–81. http://www.viam-works.ruhttps://doi.org/10.18577/2307-6046-2020-0-3-74-81

Gadalov, V.N., Bredikhina, O.A., Kamyshnikov, Yu.P., Skripkina, Yu.V., Shkodkin, V.I., and Kvashnin, B.N., Using the sclerometry method for evaluating metals and alloys with electrophysical coatings, Proc. Int. Sci.-Tech. Conf. “New Materials and Technologies in Mechanical Engineering,” Bryansk: Bryansk State Eng.-Tech. Acad., 2006, pp. 10–15.

Belous, V.A., Lunev, V.M., Pavlov, V.S., and Turchina, A.K., Quantitative definition of thin metal films adhesion with glass, Vopr. Atom. Nauki Tekh., Fiz. Radiats. Povrezh. Radiats. Materialoved., 2006, no. 4, pp. 221–223.

Useinov, A.S., Kravchuk, K.S., and Maslennikov, I.I., Indentation. Measurement of hardness and crack resistance of coatings, Nanoindustriya, 2013, no. 7 (45), pp. 48–57.

Lvova, N.A., Kravchuk, K.S., and Shirokov, I.A., Algorithms for processing scratch images in the sclerometry method, Phys. Solid State, 2013, vol. 55, no. 8, pp. 1681–1689. https://doi.org/10.1134/S1063783413080179

Kablov, E.N., Innovations of VIAM as part of implementing the “Strategic Directions of Development of Materials and Technologies of Their Processing for the Period up to 2030,” Aviats. Mater. Tekhnol., 2015, no. 1 (34), pp. 3–33. https://doi.org/10.18577/2071-9140-2015-0-1-3-33

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by M. Drozdova

Rights and permissions

About this article

Cite this article

Veshkin, E.A., Semenychev, V.V., Postnov, V.I. et al. Regularities of Change in Microhardness in the High Section of Fiberglass, Scratch Resistance by Indenter, and Formation of Texture of Sclerometric Grooves. Inorg. Mater. Appl. Res. 13, 21–28 (2022). https://doi.org/10.1134/S2075113322010403

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113322010403