Abstract

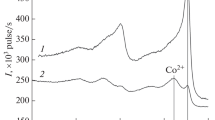

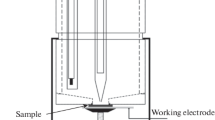

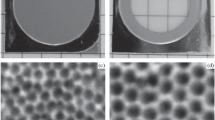

The results of studying the morphology and crystalline, local atomic, and chemical structure of iron(III) oxide coatings on the surface of porous aluminum oxide with different morphology using methods of scanning-electron- and atomic-force microscopy, X-ray phase analysis, X-ray photoelectron spectroscopy, as well as X-ray absorption near edge structure (XANES) spectroscopy are presented. Films of porous alumina are synthesized by the two-stage anodic oxidation of aluminum in 0.3 M aqueous solutions of sulfuric and oxalic acids. To change the pore diameter, some of the films are etched in a phosphoric-acid solution. Samples of iron oxide nanocoatings are obtained by oxidation of iron films in air deposited onto porous alumina substrate matrices by magnetron sputtering at a temperature of 300°C for 3 h. It is shown that oxidation leads to a twofold increase in the coating thickness of the control sample and is associated with an increase in the density of iron oxide compared to pure iron. With a change in the nanoporous structure on the surface of the substrates, the morphological features of the coatings change: there is overgrowth of the pores with iron oxide. Controlling the processes leading to such overgrowth will make it possible to carry out a targeted change in the structure-sensitive properties of composite structures based on iron oxide.

Similar content being viewed by others

REFERENCES

C. Chen, J. Ge, Y. Gao, C. Lei, J. Cui, J. Zeng, and M. Gao, Wiley Interdiscip. Rev.: Nanomed. Nanobiotechnol. 14, 1740 (2022). https://www.doi.org/10.1002/wnan.1740

M. G. el Schneider, M. J. Martin, J. Otarola, E. Vakarelska, V. Simeonov, V. Lassalle, and M. Nedyalkova, Pharmaceutics 14, 204 (2022). https://www.doi.org/10.3390/pharmaceutics14010204

P. Kumar, V. Tomar, D. Kumar, JoshiR. Kumar, and M. Nemival, Tetrahedron 106–107, 132641 (2022). http://www.doi.org/10.1016/j.tet.2022.132641

F. Yakasai, M. Z. Jaafar, S. Bandyopadhyay, A. Agi, and M. A. Sidek, J. Pet. Sci. Eng. 208, 109438 (2022). https://www.doi.org/10.1016/j.petrol.2021.109438

C. D. Powell, A. W. Lounsbury, Z. S. Fishman, C. L. Coonrod, M. J. Gallagher, D. Villagran, J. B. Zimmerman, L. D. Pfefferle, and M. S. Wong, Nano Convergence 8, 8 (2021). http://www.doi.org/10.1186/s40580-021-00258-7

N. Song, H. Jiang, T. Cui, L. Chang, and X. Wang, Micro Nano Lett. 7, 943 (2012). https://www.doi.org/ 10.1049/mnl.2012.0631

B. Sun, J. Horvat, H. S. Kim, W.-S. Kim, J. Ahn, and G. Wang, J. Phys. Chem. C 114, 18753 (2010). https://www.doi.org/10.1021/jp102286e

A. Kumar and Y. Kamlesh, Mater. Res. Express 4, 075003 (2017). https://www.doi.org/10.1088/2053-1591/aa75e9

K. S. Napolskii, I. V. Roslyakov, A. Y. Romanchuk, O. O. Kapitanova, A. S. Mankevich, V. A. Lebedev, and An. A. Eliseev, J. Mater. Chem. 22, 11922 (2012). https://www.doi.org/10.1039/C2JM31710A

I. V. Roslyakov, A. P. Chumakov, An. A. Eliseev, A. P. Leontiev, O. V. Konovalov, K. S. Napolskii, J. Phys. Chem. C 125, 9287 (2021). http://www.doi.org/10.1021/acs.jpcc.1c01482

A. Ruiz-Clavijo, O. Caballero-Calero, and M. Martín-González, Nanoscale 13, 2227 (2021). https://www.doi.org/10.1039/D0NR07582E

R. G. Valeev, A. L. Trigub, Ya. V. Zubavichus, F. Z. Gil’mutdinov, I. A. El’kin, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 11, 879 (2017). 10.1134/S1027451017040310 https://www.doi.org/10.7868/S0207352817080145

A. I. Chukavin, R. G. Valeev, Ya. V. Zubavichus, A. L. Trigub, and A. N. Beltyukov, J. Struct. Chem. 58, 1236 (2017). https://doi.org/10.1134/S0022476617060233

A. H. A. Elmekawy, E. G. Iashina, I. S. Dubitskiy, S. V. Sotnichuk, I. V. Bozhev, D. A. Kozlov, K. S. Napolskii, D. Menzel, and A. A. Mistonov, J. Magn. Magn. Mater. 532, 167951 (2022). http://www.doi.org/10.1016/j.jmmm.2021.167951

R. G. Valeev and A. S. Alalykin, Nanotechnol. Russ. 14, 346 (2019). https://doi.org/10.1134/S199507801904013X

V. A. Kotenev, M. R. Kiselev, V. V. Vysotskii, A. A. Averin, and A. Yu. Tsivadze, Prot. Met. Phys. Chem. Surf. 52, 825 (2016). https://doi.org/10.1134/S2070205116050154

A. A. Ots, Corrosion and Wear of Heating Surfaces of Boilers (Energoatomizdat, Moscow, 1987) [in Russian].

K. V. Klementev, Nucl. Instrum. Methods Phys. Res., Sect. A 448, 299 (2000). http://www.doi.org/10.1016/S0168-9002(99)00710-X

C. D. Wagner, W. M. Rigs, L. E. Davis, and J. F. Moulder, Handbook of X-Ray Photoelectron Spectroscopy: A Reference Book of Standard Data for Use in X-Ray Photoelectron Spectroscopy, Ed. by G. E. Muilenberg (Perkin-Elmer, Eden Prairie, 1979).

O. Kubaschewski and B. E. Hopkins, Oxidation of Metals and Alloys (Butterworths, London, 1953; Metallurgiya, Moscow, 1965).

ACKNOWLEDGMENTS

The studies were carried out using the equipment of the Center for Collective Use “Center for Physical and Physical and Chemical Methods of Analysis, Study of the Properties and Characteristics of Surfaces, Nanostructures, Materials, and Products”, Udmurt Federal Research Center, Ural Branch, Russian Academy of Sciences.

Funding

The study was supported by the Ministry of Science and Higher Education of Russia under agreement no. 075-15-2021-1351.

V.V. Kriventsov is thankful to the Ministry of Science and Higher Education of the Russian Federation for financial support within the framework of the state task for the Institute of Catalysis of the Siberian Branch of the Russian Academy of Sciences. Synchrotron studies were carried out using equipment of the Center for Collective Use “Siberian Center for Synchrotron Radiation” based on VEPP-4–VEPP-2000 at the Institute of Nuclear Physics, Siberian Branch, Russian Academy of Sciences with the financial support of the state task of the Institute of Catalysis, Siberian Branch, Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by S. Rostovtseva

Rights and permissions

About this article

Cite this article

Valeev, R.G., Beltiukov, A.N., Chukavin, A.I. et al. Synthesis and Investigations of the Morphology and Structure of Fe2O3 Nanocoatings on Porous Al2O3 Obtained by the Oxidation of Magnetron-Deposited Fe Films. J. Surf. Investig. 17, 673–680 (2023). https://doi.org/10.1134/S1027451023030333

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451023030333