Abstract

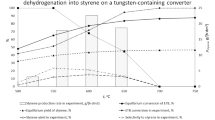

It was shown that the method for the incorporation of a catalytic tungsten component into a porous ceramic converter has a major effect on the activity and selectivity of cumene-to-AMS dehydrogenation. Specifically, the activity of a surface-modified tungsten-containing converter exceeded by more than 2.5 orders of magnitude the activity of a converter with tungsten incorporated by thermochemical sintering of the initial blend. It was further found that the performance of hydrocarbon dehydrogenation in converter channels nearly doubles that of the process occurring over a granular catalyst with an equivalent composition. It was also demonstrated that the process performance can be enhanced by removing extra-pure hydrogen from the reaction system through a palladium-containing membrane. Cumene dehydrogenation in catalytic converters was identified as a zero-order reaction.

Similar content being viewed by others

REFERENCES

Zuo, C. and Su, Q., Molecules, 2023, vol. 28, no. 8, p. 3594. https://doi.org/10.3390/molecules28083594

Nawaz, Z., Rev. Chem, Eng., 2015, vol. 31, no. 5, pp. 413–436. https://doi.org/10.1515/revce-2015-0012

Sanfilippo, D., Cattech., 2000, vol. 4, pp. 56–73. https://doi.org/10.1023/A:1011947328263

Bricker, J.C., Topics Catal., 2012, vol. 55, nos. 19–20, pp. 1309–1314. https://doi.org/10.1007/s11244-012-9912-1

Vora, B.V., Topics Catal., 2012, vol. 55, no. 19–20, pp. 1297–1308. https://doi.org/10.1007/s11244-012-9917-9

Julbe, A., Farrusseng, D., and Guizard, C., J. Membran. Sci., 2001, vol. 181, no. 1, pp. 3–20. https://doi.org/10.1016/S0376-7388(00)00375-6

Nettleship, I., Key Eng. Mater., 1996, vol. 122, pp. 305–324. https://doi.org/10.4028/www.scientific.net/KEM.122-124.305

Ohji, T. and Fukushima, M., Int. Mater. Rev., 2012, vol. 57, no. 2, pp. 115–131. https://doi.org/10.1179/1743280411Y.0000000006

Borovinskaya, I.P., Manukyan, K., and Mukasyan, A.S., Ceram. Modern Technol., 2019, vol. 1, no. 1, pp. 1–49. https://doi.org/10.29272/cmt.2018.0012

Ceramic Catalysts: Materials, Synthesis, and Applications, Kurian, M., Thankachan, S., and Nair, S.S., Eds., Elsevier, 2023.

Zha, H.-k., Yi, W.-q., Li, J.-w., Shi, J., Li, J.-c., Tang, W.-m., Lin, Y.-h., Zhu, K.-s., Cheng, J.-g., and Liu, G.-c., Silicon, 2023, pp. 1–23. https://doi.org/10.1007/s12633-023-02525-0

Rzig, R., Troudi, F., Ben Khedher, N., Boukholda, I., Aziz Alshammari, F., and Khalaf Alshammari, N., ACS Omega, 2022, vol. 7, no. 15, pp. 13280–13289. https://doi.org/10.1021/acsomega.2c00907

Lauriat, G. and Ghafir, R., Forced Convective Heat Transfer in Porous Media, Vafai, K., Ed., in Handbook of Porous Media, New York: Dekker, 2000, pp. 201–267.

Sun, T., Huang, X., Qu, Y., Wang, F., and Chen, Y., Appl. Thermal Eng., 2020, vol. 173, p. 115211. https://doi.org/10.1016/j.applthermaleng.2020.115211

Shelepova, E.V., Vedyagin,, A.A., Mishakov, I.V., and Noskov, A.S., Catal. Sustainable Energ., 2014, vol. 2, no. 1, pp. 1–9. https://doi.org/10.2478/cse-2014-0001

Gobina, E., Hou, K., and Hughes, R., Chem. Eng. Sci., 1995, vol. 50, no. 14, pp. 2311–2319. https://doi.org/10.1016/0009-2509(95)00059-E

Basov, N.L., Ermilova, M.M., Orekhova, N.V., and Yaroslavtsev, A.B., Russ. Chem. Rev., 2013, vol. 82, no. 4, pp. 352–368. https://doi.org/10.1070/RC2013v082n04ABEH004324

Abdalla, B.K. and Elnashaie, S.S.E.H., J. Membrane Sci., 1993, vol. 85, no. 3, pp. 229–239. https://doi.org/10.1016/0376-7388(93)85277-4

Fedotov, A.S., Tsodikov, M.V., Yaroslavtsev, A.B., Processes, 2022, vol. 10, no. 10, p. 2060. https://doi.org/10.3390/pr10102060

Fedotov, A.S., Uvarov, V.I., Tsodikov, M.V., Paul, S., Simon, P., Marinova, M., and Dumeignil, F., Chem. Eng. Proc.-Process Intensificat., 2021, vol. 160, p. 108265. https://doi.org/10.1016/j.cep.2020.108265

Fedotov, A.S., Grachev, D.Yu., Bagdatov, R.A., Tsodikov, M.V., Uvarov, V.I., Kapustin, R.D., Paul, S., and Dumeignil, F., Petrol. Chem., 2023, vol. 63, pp. 453–462. https://doi.org/10.1134/S0965544123030143

Chistyakov, A.V., Zharova, P.A., Tsodikov, M.V., Nikolaev, S.A., Krotova, I.N., and Ezzhelenko, D.I., Kinet Catal., 2016, vol. 57, pp. 803–811. https://doi.org/10.1134/S0023158416060045]

Ryashentseva, M.A. and Minchaev, Kh.M., Renii i ego soedineniya v geterogennom katalize (Rhenium and Its Compounds in Heterogeneous Catalysis), Moscow: Nauka, 1983.

Ryashentseva, M.A., Russ. Chem. Rev., 1998, vol. 67, no. 2, pp. 157–177. https://doi.org/10.1070/RC1998v067n02ABEH000390

Ryashentseva, M.A., Vestn. MITKhT, 2007, vol. 2, no. 2, p. 12.

Lai, C., Wang, J., Zhou, F., Liu, W., and Miao, N., J. Alloys Compd., 2018, vol. 735, pp. 2685–2693. https://doi.org/10.1016/j.jallcom.2017.11.064

Romanyuk, A., Steiner, R., Oelhafen, P., Biskupek, J., Kaiser, U., Mathys, D., and Spassov, V., J. Phys. Chem., 2008, vol. 112, no. 30, pp. 11090–11092. https://doi.org/10.1021/jp803844d

Wilken, T.R., Morcom, W.R., and Wert, C.A., Metallurg. Transact., 1976, vol. 7, no. 4, pp. 589–597. https://doi.org/10.1007/BF02698592

Funding

This study was funded by the Russian Science Foundation (project no. 23-13-00085).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest requiring disclosure in this article.

Additional information

Publisher's Note. Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fedotov, A.S., Grachev, D.Y., Kapustin, R.D. et al. Dehydrogenation of Cumene to α-Methylstyrene over Tungsten-Containing Porous Ceramic Converters. Pet. Chem. 63, 1110–1118 (2023). https://doi.org/10.1134/S0965544123060294

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965544123060294