Abstract

A brief review is presented of studies in the field of heat-transfer enhancement and for increasing the critical heat fluxes (CHFs) during boiling and evaporation in thin horizontal liquid layers. The effect of the liquid layer height on heat-transfer efficiency at various heat fluxes has been analyzed. Decreasing the film thickness enhances heat transfer at low heat fluxes, while heat-transfer augmentation occurs at high heat fluxes in films whose height is greater than the capillary constant. The heat-transfer coefficient (HTC) first rises with a layer height, and then decreases to pool boiling values. The structures formed in thin liquid layers are examined in a wide range of layer heights and pressures. The mechanisms of formation of various structures and the effect on heat-transfer enhancement depending on process conditions were also discussed. The existence of regimes with heat-transfer enhancement during evaporation of a liquid layer at reduced pressures has been demonstrated. The heat-transfer coefficient in these regimes is higher than during nucleate boiling in a layer of the same height at a higher pressure. This is caused by the effect of the structures formed in these regimes. It has been found that CHF rises with an increase in the layer thickness to pool boiling values. The heat-transfer coefficients during nucleate boiling in thin films on capillary-porous surfaces are approximately three to five times higher than on a smooth surface. It has been demonstrated that there is an optimal film surface at low pressures, which provides higher heat-transfer coefficients than those on a smooth surface. Higher heat conductivity coatings of the same shape considerably increase CHFs in the entire pressure range for liquid layer thicknesses of the order of the capillary constant. It was found that, with a characteristic spacing between the coating fins, which is equal to the capillary constant of the liquid, the highest heat-transfer coefficients are attained in the experiments.

Similar content being viewed by others

Notes

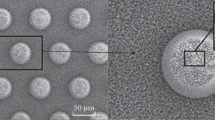

The solid component of a part is manufactured by selective laser melting (SLM) technology, and the porous coating by the selective laser sintering (SLS) technology.

REFERENCES

G. N. Kruzhilin, “Heat transfer from a horizontal plate to a boiling liquid under free convection,” Dokl. Akad. Nauk SSSR 58, 1657–1660 (1947).

W. Fritz, “Berechnung des maximalen Volumens von Dampfblasen,” Phys. Z. 36, 379–384 (1935).

M. Jakob and W. Linke, “Der Wärmeübergang beim Verdampfen von Flüssigkeiten an senkrechten und waagerechten Flächen,” Phys. Z. 36, 267–280 (1935).

S. S. Kutateladze, Heat Transfer in Condensation and Boiling, 2nd ed. (Meshgiz, Moscow, 1952; U.S. Atomic Energy Commission Technical Information Service, Oak Ridge, Tenn., 1952).

V. I. Tolubinskii, V. A. Antonenko, and Yu. N. Ostrovskii, “Heat transfer in vaporization in thin films,” Prom. Teplotekh. 3 (3), 9–13 (1961).

V. A. Grigor’ev and A. S. Dudkevich, “Boiling of cryogenic liquids in a thin film,” Teploenergetika, No. 12, 54–57 (1970).

V. A. Grigor’ev, A. S. Dudkevich, and Yu. M. Pavlov, “Boiling of cryogenic liquids in a thin film,” Vopr. Radioelektron., Ser.: Tepl. Rezhimy, Termostatirovanie Okhlazhd. Radioelektron. Appar., No. 1, 83–90 (1970).

V. A. Grigor’ev, Yu. M. Pavlov, and E. V. Ametistov, Boiling of Cryogenic Liquids (Energiya, Moscow, 1977) [in Russian].

A. N. Pavlenko and D. V. Kuznetsov, “Development of methods for heat transfer enhancement during nitrogen boiling to ensure stabilization of HTS devices,” J. Eng. Thermophys. 30, 526–562 (2021). https://doi.org/10.1134/S1810232821040019

K. Nishikawa, H. Kusuda, K. Yamasaki, and K. Tanaka, “Nucleate boiling at low liquid levels,” Bull. JSME 10, 328–338 (1967). https://doi.org/10.1299/jsme1958.10.328

V. I. Tolubinskii, Heat Exchange at Boiling (Naukova dumka, Kiev, 1980) [in Russian].

V. I. Tolubinskii, V. A. Antonenko, A. A. Kriveshko, and Yu. N. Ostrovskii, “Suppression of nucleate boiling in a stationary liquid film,” Teplofiz. Vys. Temp. 15, 822–827 (1977).

K. Nishikawa, “Nucleate boiling in liquid film,” Trans. Jpn. Soc. Mech. Eng. 34, 935–949 (1968).

S. Gong, W. Ma, and H. Gu, “An experimental investigation on bubble dynamics and boiling crisis in liquid films,” Int. J. Heat Mass Transfer 79, 694–703 (2014). https://doi.org/10.1016/j.ijheatmasstransfer.2014.08.065

A. Ono and H. Sakashita, “Liquid–vapor structure near heating surface at high heat flux in subcooled pool boiling,” Int. J. Heat Mass Transfer 50, 3481–3489 (2007). https://doi.org/10.1016/j.ijheatmasstransfer.2007.01.026

H. Sakashita and A. Ono, “Boiling behaviors and critical heat flux on a horizontal plate in saturated pool boiling of water at high pressures,” Int. J. Heat Mass Transfer 52, 744–750 (2009). https://doi.org/10.1016/j.ijheatmasstransfer.2008.06.040

V. I. Deev, V. V. Gusev, and G. P. Dubrovskii, “Investigation of the mechanism of boiling water at reduced pressures,” Teploenergetika, No. 8, 73– 75 (1965).

V. I. Tolubinskii, V. A. Antonenko, and Yu. N. Ostrovskii, “Boundaries of the region of existence of nucleate boiling of a saturated liquid,” Teplofiz. Teplotekh., No. 34, 3–6 (1978).

M. K. Bezrodnyi, I. L. Pioro, and T. O. Kostyuk, Transport Processes in Two-Phase Thermosyphon Systems. Theory and Practice, 2nd ed. (Fakt, Kyiv, 2005) [in Russian].

M. Y. Shukla and S. G. Kandlikar, “Influence of liquid height on bubble coalescence, vapor venting, liquid return, and heat transfer in pool boiling,” Int. J. Heat Mass Transfer 173, 121261 (2021). https://doi.org/10.1016/j.ijheatmasstransfer.2021.121261

I. L. Pioro, “Boiling heat transfer characteristics of thin liquid layers in a horizontally flat two-phase thermosiphon,” in Preprints of the 10th Int. Heat Pipe Conf., Stuttgart, Germany, Sept. 1997, paper H1-5.

I. L. Pioro, “Experimental evaluation of constants for the Rohsenow pool boiling correlation,” Int. J. Heat Mass Transfer 42, 2003–2013 (1999). https://doi.org/10.1016/S0017-9310(98)00294-4

I. L. Pioro, W. Rohsenow, and S. S. Doerffer, “Nucleate pool-boiling heat transfer. I: Review of parametric effects of boiling surface,” Int. J. Heat Mass Transfer 47, 5033–5044 (2004). https://doi.org/10.1016/j.ijheatmasstransfer.2004.06.019

I. L. Pioro, W. Rohsenow, and S. S. Doerffer, “Nucleate pool-boiling heat transfer. II: Assessment of prediction methods,” Int. J. Heat Mass Transfer 47, 5045–5057 (2004). https://doi.org/10.1016/j.ijheatmasstransfer.2004.06.020

V. V. Yagov, “Is a crisis in pool boiling actually a hydrodynamic phenomenon?,” Int. J. Heat Mass Transfer 73, 265–273 (2014). https://doi.org/10.1016/j.ijheatmasstransfer.2014.01.076

V. I. Zhukov and A. N. Pavlenko, “Heat transfer and critical phenomena during evaporation and boiling in a thin horizontal liquid layer at low pressures,” Int. J. Heat Mass Transfer 117, 978–990 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2017.10.060

V. I. Zhukov and A. N. Pavlenko, “Regimes of intensified heat transfer during evaporation of thin horizontal liquid layers at reduced pressures,” Tech. Phys. Lett. 44, 508–510 (2018). https://doi.org/10.1134/S1063785018060299

I. I. Gogonin, A. R. Dorokhov, and V. I. Zhukov, “Study of evaporation from a thin oil layer under vacuum conditions,” Izv. Sib. Otd. Akad. Nauk SSSR, Ser. Tekh. Nauk, No. 3, 8–13 (1989).

V. I. Zhukov, “Enhanced heat transfer under conditions of liquid boiling in a thin layer at reduced pressure,” Theor. Found. Chem. Eng. 45, 690–694 (2011).

V. I. Zhukov and A. N. Pavlenko, “Critical phenomena at evaporation in a thin liquid layer at reduced pressures,” J. Eng. Thermophys. 22, 257–287 (2013). https://doi.org/10.1134/S1810232813040012

V. I. Zhukov, A. N. Pavlenko, Yu. V. Nagaitseva, and D. Vaiss, “Effect of the layer height on heat transfer and the critical heat flux in evaporation of a fluid under low pressures,” High Temp. 53, 690–696 (2015). https://doi.org/10.1134/S0018151X15050284

V. I. Zhukov and A. N. Pavlenko, “Effect of the height of the horizontal layer of liquid on the development of critical phenomena in evaporation at reduced pressures,” Heat Transfer Res. 49, 979–990 (2018). https://doi.org/10.1615/HeatTransRes.2017016778

V. I. Zhukov and A. N. Pavlenko, “The mechanism of surface cooling by a horizontal layer of liquid evaporating at low reduced pressures,” AIP Adv. 11, 015341 (2021). https://doi.org/10.1063/5.0023668

L. N. Howard, “Convection at high Rayleigh number,” in Proc. of the 11th Int. Congr. on Applied Mechanics, Munich, Germany, 1964 (Springer, Berlin, 1966), pp. 1109–1115. https://doi.org/10.1007/978-3-662-29364-5_147

R. F. Gaertner, “Photographic study of nucleate pool boiling on a horizontal surface,” J. Heat Transfer 87, 17–27 (1965). https://doi.org/10.1115/1.3689038

H. S. Ahn and M. H. Kim, “Visualization study of critical heat flux mechanism on a small and horizontal copper heater,” Int. J. Multiphase Flow 41, 1–12 (2012). https://doi.org/10.1016/j.ijmultiphaseflow.2011.12.006

I. C. Bang, S. H. Chang, and W.-P. Baek, “Visualization of a principle mechanism of critical heat flux in pool boiling,” Int. J. Heat Mass Transfer 48, 5371–5385 (2005). https://doi.org/10.1016/j.ijheatmasstransfer.2005.07.006

A. M. Bhat, R. Prakash, and J. S. Saini, “On the mechanism of macrolayer formation in nucleate pool boiling at high heat flux,” Int. J. Heat Mass Transfer 26, 735–740 (1983). https://doi.org/10.1016/0017-9310(83)90024-8

A. K. Rajvanshi, J. S. Saini, and R. Prakash, “Investigation of macrolayer thickness in nucleate pool boiling at high heat flux,” Int. J. Heat Mass Transfer 35, 343–350 (1992).

A. Ono and H. Sakashita, “Liquid–vapor structure near heating surface at high heat flux in subcooled pool boiling,” Int. J. Heat Mass Transfer 50, 3481–3489 (2007). https://doi.org/10.1016/j.ijheatmasstransfer.2007.01.026

T. Kumada and H. Sakashita, “Pool boiling heat transfer — II. Thickness of liquid macrolayer formed beneath vapor masses,” Int. J. Heat Mass Transfer 38, 979–987 (1995). https://doi.org/10.1016/0017-9310(94)00225-K

K. A. Kumar, I. S. Raj, P. Jeyaraman, N. Tamilselvam, and B. R. Aravindraj, “The development of macrolayer thickness of water in the pool boiling regime,” Int. J. Ambient Energy 41, 1057–1059 (2020).

S. Gong, W. Ma, C. Wang, Y. Mei, and H. Gu, “An investigation on dynamic thickness of a boiling liquid film,” Int. J. Heat Mass Transfer 90, 636–644 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.07.011

M.-C. Chyu, “Evaporation of macrolayer in nucleate boiling near burnout,” Int. J. Heat Mass Transfer 30, 1531–1538 (1987). https://doi.org/10.1016/0017-9310(87)90184-0

K. O. Pasamehmetoglu, P. R. Chappidi, C. Unal, and R. A. Nelson, “Saturated pool nucleate boiling mechanisms at high heat fluxes,” Int. J. Heat Mass Transfer 36, 3859–3868 (1993).

V. K. Dhir and S. P. Liaw, “Framework for s unified model for nucleate and transition pool boiling,” J. Heat Transfer 111, 739–746 (1989). https://doi.org/10.1115/1.3250745

J. H. Lay and V. K. Dhir, “Shape of vapor stem during nucleate boiling of saturated liquids,” J. Heat Transfer 117, 394–401 (1995). https://doi.org/10.1115/1.2822535

K. Sefiane, D. Benielli, and A. Steinchen, “A new mechanism for pool boiling crisis, recoil instability and contact angle influence,” Colloids Surf., A 142, 361–373 (1998). https://doi.org/10.1016/S0927-7757(98)00614-1

T. G. Theofanous, J. P. Tu, A. T. Dinh, and T. N. Dinh, “The boiling crisis phenomenon. Part I: Nucleation and nucleate boiling heat transfer,” Exp. Therm. Fluid Sci. 26, 775–792 (2002). https://doi.org/10.1016/S0894-1777(02)00192-9

B. V. Deryagin, N. V. Churaev, and V. M. Muller, Surface Forces (Nauka, Moscow, 1985; Consultants Bureau, New York, 1987).

T. G. Theofanous, T. N. Dinh, J. P. Tu, and A. T. Dinh, “The boiling crisis phenomenon. Part II: Dryout dynamics and burnout,” Exp. Therm. Fluid Sci. 26, 793–810 (2002). https://doi.org/10.1016/S0894-1777(02)00193-0

V. I. Tolubinskii, V. A. Antonenko, and G. V. Ivanenko, “Effect of liquid layer thickness on critical thermal loads at boiling,” Prom. Teplotekh. 10 (2), 3–6 (1988).

S. S. Kutateladze, “Hydromechanical model of heat transfer crisis in a boiling liquid with free convection,” Zh. Tekh. Fiz. 20, 1389–1392 (1950).

V. V. Yagov, “Physical model and calculation formula for critical heat fluxes with nucleate pool boiling of liquids,” Therm. Eng. 35, 333–339 (1988).

L. D. Landau, “On the theory of slow combustion,” Zh. Eksp. Teor. Fiz. 14, 240–245 (1944).

N. Zuber, “On the stability of boiling heat transfer,” J. Fluids Eng. 80, 711–714 (1958). https://doi.org/10.1115/1.4012484

J. H. Lienhard and V. K. Dhir, “Hydrodynamic prediction of peak pool-boiling heat fluxes from finite bodies,” J. Heat Transfer 95, 152–158 (1973). https://doi.org/10.1115/1.3450013

V. I. Zhukov and A. N. Pavlenko, “Crisis of nucleate boiling in a finite-height horizontal layer of liquid,” J. Eng. Thermophys. 29, 1–13 (2020). https://doi.org/10.1134/S1810232820010014

A. N. Pavlenko, “On the physics of the development of boiling crisis phenomena (comments on the article of E. D. Fedorovich "On the expediency of develo** a two-stage model of boiling crisis of a liquid wetting a heating surface”),” Therm. Eng. 67, 853–859 (2020). https://doi.org/10.1134/S0040601520110099

G. Liang and I. Mudawar, “Review of pool boiling enhancement by surface modification,” Int. J. Heat Mass Transfer 128, 892–933 (2019). https://doi.org/10.1016/j.ijheatmasstransfer.2018.09.026

M. P. Chinmay and S. G. Kandlikar, “Review of the manufacturing techniques for porous surfaces used in enhanced pool boiling,” Heat Transfer Eng. 35, 887–902 (2014). https://doi.org/10.1080/01457632.2014.862141

U. Sajjad, A. Sadeghianjahromi, H. M. Ali, and C.‑C. Wang, “Enhanced pool boiling of dielectric and highly wetting liquids — A review on enhancement mechanisms,” Int. Commun. Heat Mass Transfer 119, 104950 (2020). https://doi.org/10.1016/j.icheatmasstransfer.2020.104950

D. H. Min, G. S. Hwang, Y. Usta, O. N. Cora, M. Koc, and M. Kaviany, “2-D and 3-D modulated porous coatings for enhanced pool boiling,” Int. J. Heat Mass Transfer 52, 2607–2613 (2009). https://doi.org/10.1016/j.ijheatmasstransfer.2008.12.018

X. Ji, J. Xu, Z. Zhao, and W. Yang, “Pool boiling heat transfer on uniform and non-uniform porous coating surfaces,” Exp. Therm. Fluid Sci. 48, 198–212 (2013). https://doi.org/10.1016/j.expthermflusci.2013.03.002

M. M. Rahman, J. Pollack, and M. McCarthy, “Increasing boiling heat transfer using low conductivity materials,” Sci. Rep. 5, 13145 (2015). https://doi.org/10.1038/srep13145

S. Wiriyasart and P. Naphon, “Fill ratio effects on vapor chamber thermal resistance with different configuration structures,” Int. J. Heat Mass Transfer 127, 164–171 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2018.07.029

J. A. Weibel, S. V. Garimella, and M. T. North, “Characterization of evaporation and boiling from sintered powder wicks fed by capillary action,” Int. J. Heat Mass Transfer 53, 4204–4215 (2010). https://doi.org/10.1016/j.ijheatmasstransfer.2010.05.043

Y. Tang, J. Zeng, S. Zhang, C. Chen, and J. Chen, “Effect of structural parameters on pool boiling heat transfer for porous interconnected microchannel nets,” Int. J. Heat Mass Transfer 93, 906–917 (2016). https://doi.org/10.1016/j.ijheatmasstransfer.2015.11.009

D. Deng, Q. Huang, Y. **e, X. Huang, and X. Chu, “Thermal performance of composite porous vapor chambers with uniform radial grooves,” Appl. Therm. Eng. 125, 1334–1344 (2017). https://doi.org/10.1016/j.applthermaleng.2017.07.108

C. Li, G. P. Peterson, and Y. X. Wang, “Evaporation/boiling in thin capillary wicks (I) — Wick thickness effects,” J. Heat Transfer 128, 1312–1319 (2006). https://doi.org/10.1115/1.2349507

T. Li and G. P. Peterson, “Evaporation/boiling in thin capillary wicks (II) — Effects of volumetric porosity and mesh size,” J. Heat Transfer 128, 1320–1328 (2006). https://doi.org/10.1115/1.2349508

V. I. Tolubinskii, V. A. Antonenko, Yu. N. Ostrovskii, and E. N. Shevchuk, “Limiting heat flux densities at liquid evaporation in capillaries of wicks of low-temperature heat pipes,” Teplofiz. Vys. Temp. 18, 367–373 (1980).

F. J. Hong, P. Cheng, H. Y. Wu, and Z. Sun, “Evaporation/boiling heat transfer on capillary feed copper particle sintered porous wick at reduced pressure,” Int. J. Heat Mass Transfer 63, 389–400 (2013). https://doi.org/10.1016/j.ijheatmasstransfer.2013.03.086

J.-H. Liou, C.-W. Chang, C. Chao, and S.-C. Wong, “Visualization and thermal resistance measurement for the sintered meshwick evaporator in operating flat-plate heat pipes,” Int. J. Heat Mass Transfer 53, 1498–1506 (2010). https://doi.org/10.1016/j.ijheatmasstransfer.2009.11.046

S. C. Wong, J. H. Liou, and C. W. Chang, “Evaporation resistance measurement with visualization for sintered copper-powder evaporator in operating flat-plate heat pipes,” Int. J. Heat Mass Transfer 53, 3792–3798 (2010). https://doi.org/10.1016/j.ijheatmasstransfer.2010.04.031

C. Zhang, F. Hong, and P. Cheng, “Simulation of liquid thin film evaporation and boiling on a heated hydrophilic microstructured surface by Lattice Boltzmann method,” Int. J. Heat Mass Transfer 86, 629–638 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.03.029

V. P. Bessmeltsev, A. N. Pavlenko, and V. I. Zhukov, “Development of a technology for creating structured capillary-porous coatings by means of 3D printing for intensification of heat transfer during boiling,” Optoelectron., Instrum. Data Process. 55, 554–563 (2019). https://doi.org/10.3103/S8756699019060049

A. N. Pavlenko and V. V. Lel, “Heat transfer and crisis phenomena in falling films of cryogenic liquid,” Russ. J. Eng. Thermophys. 7, 177–210 (1997).

N. Read, W. Wang, K. Essa, and M. M. Attallah, “Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development,” Mater. Des. 65, 417–424 (2015). https://doi.org/10.1016/j.matdes.2014.09.044

V. I. Zhukov, A. N. Pavlenko, and D. A. Shvetsov, “The effect of pressure on heat transfer at evaporation/boiling in horizontal liquid layers of various heights on a microstructured surface produced by 3D laser printing,” Int. J. Heat and Mass Transfer 163, 120488 (2020). https://doi.org/10.1016/j.ijheatmasstransfer.2020.120488

D. A. Shvetsov, A. N. Pavlenko, A. E. Brester, and V. I. Zhukov, “A map of regimes of evaporation and boiling in the horizontal liquid layer on the modified surface,” J. Phys.: Conf. Ser. 2039, 012033 (2021). https://doi.org/10.1088/1742-6596/2039/1/012033

D. A. Shvetsov, A. N. Pavlenko, A. E. Brester, and V. I. Zhukov, “Experimental study of heat transfer during boiling in a thin layer of liquid on surfaces with structured porous coatings,” J. Phys.: Conf. Ser. 2119, 012082 (2021). https://doi.org/10.1088/1742-6596/2119/1/012082

S. G. Liter and M. Kaviany, “CHF enhancement by modulated porous-layer coating: Theory and experiment,” Int. J. Heat Mass Transfer 44, 4287–4311 (2001). https://doi.org/10.1016/S0017-9310(01)00084-9

D. A. Shvetsov, A. N. Pavlenko, and V. I. Zhukov, “Influence of the morphology of a capillary-porous coating on the evaporation and boiling of a thin liquid layer,” in Technologies. Innovations: Collection of Scientific Papers (Nauka, Novosibirsk, 2021), pp. 104–108 [in Russian].

Funding

The study was performed under the state assignment (no. 121031800216-1) of the Institute of Thermophysics, Siberian Branch, Russian Academy of Sciences, and with the financial support of a megagrant (no. 075-15-2021-575) of the Ministry of Science and Higher Education of the Russian Federation under supervision of leading scientists.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Krasnoshchekova

Rights and permissions

About this article

Cite this article

Pavlenko, A.N., Zhukov, V.I. & Shvetsov, D.A. Crisis Phenomena and Heat-Transfer Enhancement during Boling and Evaporation in Horizontal Liquid Films (Review). Therm. Eng. 69, 886–901 (2022). https://doi.org/10.1134/S0040601522110076

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601522110076