Abstract

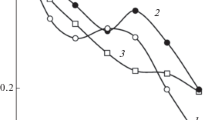

The results of studying the oxidizing roasting of vanadium slags involving CaO for the transformation of vanadium into soluble forms are discussed. Three samples of the vanadium slag are tested using CaCO3 as a reactive sample. The sequence of processes that occur during slag oxidation and the temperature range of the intense interaction of CaCO3 and vanadium oxides with the formation of calcium vanadates are determined. The effect of the roasting temperature in a range of 775–975°C and the lime module (weight ratio CaOtot/V2O5) of the charge on the completeness of access to vanadium and parameters of vanadium recovery during the sulfuric acid leaching of the cinder at pH 2.5 followed by cake washing on a filter with a solution of 3% H2SO4 is studied in detail. The selective interaction of CaCO3 with vanadium oxides is found to occur in a temperature range of 800–875°C to form calcium vanadates highly soluble in weakly acidic solutions. The degree of recovery of vanadium from a slag reaches 90–95% at the lime module of the charge of about 0.35. In the indicated temperature range, an increase in the amount of the CaCO3 additive exerts a very weak effect on the results of vanadium recovery. A further increase in the temperature leads to the violation of the selectivity of formation of calcium vanadates due to the interaction of CaCO3 with free SiO2 and other slag components. This exerts a negative effect on the results of vanadium recovery during the sulfuric acid leaching of the cinder.

Similar content being viewed by others

REFERENCES

G. V. Sadykhov, “Fundamental problems and prospects of using titanium raw materials in Russia,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall. 63 (3–4), 178–194 (2020).

L. A. Smirnov, Yu. A. Deryabin, and S. V. Shavrin, Metallurgical Processing of Vanadium-Containing Titanomagnetites (Metallurgiya, Chelyabinsk, 1990).

Yu. A. Deryabin, L. A. Smirnov, and A. A. Deryabin, Prospects of Processing of Titanomagnetites from the Chinei Deposit (Sred.-Ural. Kn. Izd., Yekaterinburg, 1999).

Ferro-Alloy Resources Limited. Vanadium Market. April 2020. http://ferro-alloy.com/ru/vanadium/vanadium-market-overview/.

B. Rohmann, “The development and operation of the iron and steel Works at Highveld Steel and Vanadium Corporation Limited Proceedings,” in Proceedings of 12th CMMJ Congress (S. Afr. Inst. Min. Metal of Geol. Soc., Johannesburg, 1982), pp. 605–615.

V. G. Mizin and E. M. Rabinovich, Complex Processing of Vanadium Raw Materials: Chemistry and Technology (UrO RAN, Yekaterinburg, 2005).

Production of Technical Vanadium Pentoxide. Technological Instruction TI 127-F-01–2002 (Tula, 2002).

N. A. Vatolin, N. G. Moleva, P. I. Volkova, and T. V. Sapozhnikova, Oxidation of Vanadium Slags (Nauka, Moscow, 1978).

A. A. Fotiev and B. V. Slobodin, Vanadates. Composition, Synthesis, Structure, and Properties (Nauka, Moscow, 1988), pp. 145–148.

G. V. Sadykhov, K. V. Goncharov, T. V. Olyunina, and D. Yu. Kashekov, “Waste slime of the V2O5 production according to the lime–sulfuric acid technology as a technical raw material for vanadium recovery,” Russ. Metall. (Metally), No. 5, 873–882 (2019).

Funding

This work was performed in terms of state assignment no. 075-00328-21-00.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Yablonskaya

Rights and permissions

About this article

Cite this article

Sadykhov, G.B., Goncharov, K.V. & Olyunina, T.V. Specific Features of the Oxidizing Roasting of Vanadium Slags with a CaCO3 Additive for the Transformation of Vanadium into Soluble Forms. Russ. Metall. 2021, 571–578 (2021). https://doi.org/10.1134/S0036029521050116

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521050116