Abstract

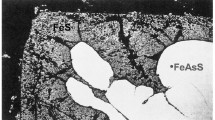

A two-stage technological scheme is proposed for the processing of pyrrhotine middlings and poor copper–nickel raw materials. The hydrolytic cleaning of cycling leaching solutions from iron is separated as a particular procedure. The laboratory studies of the two-stage sulfuric acid leaching with the hydrolytic cleaning of a cycling solution from iron is carried out for representative samples of the pyrrhotine middlings with a low nickel content (~0.7%) from Norilsk Nickel. The technology gives an oxidized ferrous cake with a low content of nonferrous and platinum metals (about 0.05%) and a sulfur–sulfide concentrate, in which all nonferrous and platinum metals and technical sulfur are concentrated. Up to 60% iron are shown to be leached from the middlings within the full cycle (two stages), and only 40% processed middlings are retained as a sulfur–sulfide concentrate containing 60–65% elemental sulfur and up to 30% gangue (rock-forming minerals).

Similar content being viewed by others

REFERENCES

S. S. Naboichenko, L. P. Ni, Ya. M. Shneerson, and L. V. Chugaev, Autoclave Hydrometallurgy of Nonferrous Metals (UGTU–UPI, Yekaterinburg, 2002).

E. F. Sinyakova, “Processes of mineral formation in a Fe–Ni–S system with platinum metal impurities,” Doctoral Dissertation in Geology–Mineralogy, Novosibirsk, 2007.

T. N. Greiver, I. G. Zaitseva, and Yu. V. Andreev, “A method for pyrrhotine concentrate processing,” SU Patent 1321764A1, 1987.

I. F. Khudyakov, A. V. Klyueva, and V. I. Smirnov, “Study of the conditions of the oxidation of divalent iron sulfate and hydrolysis of the oxidation products in autoclave processes,” Dokl. Akad. Nauk SSSR 148 (3), 654–657 (1963).

A. G. Kitai, V. A. Bryukvin, V. T. D’yachenko, A. O. Bol’shikh, and V. A. Korneev, “Physicochemical studies of the main regularities of iron(III) sulfate hydrolysis under hydrothermal conditions,” Tsvetn. Met., No. 8/9, 125 (2011).

V. T. D’yachenko, V. A. Bryukvin, A. G. Kitai, A. O. Bol’shikh, and V. A. Andrushkevich, “On the chemical passivation mechanism of the pyrrhotine concentrate during its sulfuric acid leaching,” Tsvetn. Met., No. 5, 14–17 (2011).

A. O. Bol’shikh, “Physicochemical substantiation of the organization of the leaching technology of a low-nickel pyrrhotine concentrate for Norilsk Nickel,” in Proceedings of XIII Russian Annual Conference of Young Scientists and Post-Graduate Students on Physical Chemistry and Technology of Inorganic Materials (IMET RAN, Moscow, 2017), pp. 430–432.

V. T. D’yachenko, V. A. Bryukvin, T. N. Vinetskaya, T. A. Makarenkova, A. G. Kitai, and A. O. Bol’shikh, “Physicochemical laws of the atmospheric sulfuric acid leaching of the copper–nickel concentrates from the beneficiation of disseminated ores,” Russ. Metall. (Metally), No. 7, 521–525 (2012).

V. T. D’yachenko, V. A. Bryukvin, T. N. Vinetskaya, T. A. Makarenkova, and M. A. Bol’shikh, “Physicochemical substantiation of the main regularities of the atmospheric sulfuric acid leaching of a nickel–pyrrhotine concentrate at the Norilsk Concentrating Plant,” Tsvetn. Met., No. 5, 9–13 (2011).

V. A. Bryukvin, O. I. Tsybin, V. T. D’yachenko, and M. A. Bol’shikh, “On some peculiarities of the acid leaching mechanism of pyrrhotines,” Tsvetn. Met., No. 2, 47 (2008).

V. A. Bryukvin, O. I. Tsybin, V. T. D’yachenko, and M. A. Bol’shikh, “On some peculiarities of the chemical behavior of sulfur of the pyrrhotine concentrate during its sulfuric acid leaching,” Tsvetn. Met., No. 12, 32 (2009).

Funding

This work was carried out in terms of state assignment no. 007-00129-18-00.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Yablonskaya

Rights and permissions

About this article

Cite this article

Bol’shikh, A.O., Tsybin, O.I., Bol’shikh, M.A. et al. Substantiation of the Possibility to Organize a Complex Two-Stage Sulfuric Acid Leaching Technology for Pyrrhotine Middlings. Russ. Metall. 2021, 1–6 (2021). https://doi.org/10.1134/S0036029521010031

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521010031