Abstract

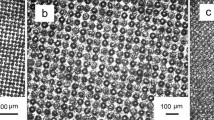

Results of studying the growth of diamond structures on steel specimens with the use of intermediate layers of molybdenum or tungsten carbide cemented by cobalt are reported. The interlayers are deposited by means of detonation spraying. Subsequent deposition of diamond films onto the clad steel specimens is formed by the gas jet method and a special thermocatalytic reactor with extended activating surfaces. The nucleation process on the interlayer surfaces is intensified by preliminary seeding of the specimens in a colloid solution containing nanodiamonds. Information about the phase and structural composition of the resultant specimens and about the film surface morphology is obtained by scanning electron microscopy, Raman spectroscopy, and X-ray diffraction analysis. The tribology of the specimens is studied with the use of hardness nansensors and by the Rockwell hardness indentation method.

Similar content being viewed by others

References

B. V. Spitsyn and L. L. Bouilov, “Vapor Growth of Diamond on Diamond and Other Surfaces,” J. Crystal Growth 52 (1), 219–226 (1981).

V. Blank, M. Popov, G. Pivovarov, et al., “Mechanical Properties of Different Types of Diamond,” Diam. Rel. Mater. 8, 1531–1535 (1999).

J. G. Buijnsters, P. Shankar, W. J. P. van Enckevort, et al., “The Adhesion of Hot-Filament CVD Diamond Films on AISI Type 316 Austenitic Stainless Steel,” Diam. Rel. Mater. 13, 848–857 (2004).

D. D. Damm, A. Contin, F. C. Barbieri, et al., “Interlayers Applied to CVD Diamond Deposition on Steel Substrate: A Review,” Coatings 7 (9), 141–166 (2017).

V. F. Neto, T. Shokuhfar, M. S. A. Oliveira, et al., “Polycrystalline Diamond Coatings on Steel Substrates,” Int. J. Nanomanufact. 2 (3), 99–115 (2008).

A. Poulon-Quintin, C. Faure, L. Teule-Gay, and J. P. Manaud, “A Multilayer Innovative Solution to Improve the Adhesion of Nanocrystalline Diamond Coatings,” Appl. Surf. Sci. 331 (1), 27–34 (2015).

M. Chandran, F. Sammler, E. Uhlmann, et al., “Wear Performance of Diamond Coated WC-Co Tools with a CrN Interlayer,” Diam Rel. Mater. 73, 47–55 (2017).

M. N. Liu, Y. B. Bian, S. J. Zheng, et al., “Growth and Mechanical Properties of Diamond Films on Cemented Carbide with Buffer Layers,” Thin Solid Films 584, 165–169 (2015).

R. Polini, M. Barletta, and G. Cristofanilli, “Wear Resistance of Nano- and Micro-Crystalline Diamond Coatings onto WC-Co with Cr/CrN Interlayers,” Thin Solid Films 519 (5), 1629–1635 (2010).

N. N. Naguib, J. W. Elam, J. Birrel, et al., “Enhanced Nucleation, Smoothness and Conformality of Ultrananocrystalline Diamond (UNCD) Ultrathin Films via Tungsten Interlayers,” Chem. Phys. Lett. 430, 345–350 (2006).

H. Liu and D. S. Dandy, Diamond Chemical Vapor Deposition Nucleation and Early Growth Stages (Noyes, New Jersey, 1995).

J. G. Buijnsters, L. Vázquez, R. E. Galindo, and J. J. ter Meulen, “Molybdenum Interlayers for Nucleation Enhancement in Diamond CVD Growth,” J. Nanosci. Nanotechnol. 10, 2885–2891 (2010).

V. Kundrát, X. Zhang, K. Cooke, et al., “A Novel Mo-W Interlayer Approach for CVD Diamond Deposition on Steel,” AIP Adv. 5, 047130 (2015).

V. Ulianitsky, A. Shtertser, S. Zlobin, and I. Smurov, “Computer-Controlled Detonation Spraying: From Process Fundamentals Toward Advanced Applications,” J. Thermal. Spray Technol. 20, 791–801 (2011).

D. V. Dudina, I. S. Batraev, Yu. V. Ulianitsky, and M. A. Korchagin, “Possibilities of the Computer-Controlled Detonation Spraying Method: A Chemistry Viewpoint,” Ceram. Int. 40, 3253–3260 (2014).

V. Ulianitsky, I. Batraev, A. Shtertser, et al., “Detonation Spraying of Refractory Metals,” in Proc. of the Int. Thermal Spray Conf., Dusseldorf (Germany), June 7–9, 2017 (Curran Assoc., Inc., Red Hook, New York, 2017), Vol. 336, pp. 572–576.

A. K. Rebrov, M. N. Andreev, T. T. B’yadovskiy, et al., “The Reactor-Activator for Gas-Jet Deposition of Diamond Structures,” Rev. Sci. Instrum. 87, 103902 (2016).

M. Yu. Plotnikov and E. V. Shkarupa, “Heterogeneous Activation of Rarefied Hydrogen in Thin Tubes,” Vacuum 129, 31–37 (2016).

A. K. Rebrov, “Possibility of Gas-Phase Synthesis of Diamond Structures,” Usp. Fiz. Nauk 187 (2), 193–200 (2017).

A. K. Rebrov, M. N. Andreev, T. T. Bieiadovskii, and K. V. Kubrak, “Growth of Diamond Structures using High Speed Gas Jet Deposition Activated in Heated Tungsten Channels,” Surf. Coat. Technol. 325, 210–218 (2017).

V. Y. Dolmatov, “Detonation Synthesis Ultradispersed Diamond: Properties and Applications,” Russ. Chem. Rev. 70, 607–626 (2001).

Q. Wei, Z. M. Yu, M. N. R. Ashfold, et al., “Fretting Wear and Electrochemical Corrosion ofWell-Adhered CVD Diamond Films Deposited on Steel Substrates with a WC-Co Interlayer,” Diam. Rel. Mater. 19, 1144–1152 (2010).

A. C. Ferrari and J. Robertson, “Raman Spectroscopy of Amorphous, Nanostructured, Diamond-Like Carbon, and Nanodiamond,” Philos. Trans. Roy. Soc. London, Ser. A 362, 2477–2512 (2004).

Q. Wei, M. N. R. Ashfold, Yu. A. Mankelevich, et al., “Diamond Growth onWC-Co Substrates by Hot Dilament Chemical Vapor Deposition: Effect of Filament-Substrate Separation,” Diam. Rel. Mater. 20, 641–650 (2011).

F. Silva, A. Gicquel, A. Tardieu, et al., “Control of an MPACVD Reactor for Polycrystalline Textured Diamond Films Synthesis: Role of Microwave Power Density,” Diam. Rel. Mater. 5, 338–344 (1996).

V. G. Ralchenko, A. A. Smolin, V. G. Pereverzev, et al., “Diamond Deposition on Steel with CVD Tungsten Intermediate Layer,” Diam. Rel. Mater. 4, 754–758 (1995).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Original Russian Text © A.K. Rebrov, I.S. Batraev, T.T. B’yadovskii, E.V. Gladkikh, A.S. Useinov, M.N. Khomyakov.

__________

Translated from Prikladnaya Mekhanika i Tekhnicheskaya Fizika, Vol. 60, No. 6, pp. 118–129, November-December, 2019.

Rights and permissions

About this article

Cite this article

Rebrov, A.K., Batraev, I.S., B’yadovskii, T.T. et al. Gas Jet Deposition of Diamond onto a Steel Surface Covered by a Tungsten Carbide or Molybdenum Layer. J Appl Mech Tech Phy 60, 1077–1087 (2019). https://doi.org/10.1134/S0021894419060130

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894419060130