Abstract

Conventional material processing approaches often achieve strengthening of materials at the cost of reduced ductility. Here, we show that high-pressure and high-temperature (HPHT) treatment can help overcome the strength-ductility trade-off in structural materials. We report an initially strong-yet-brittle eutectic high entropy alloy simultaneously doubling its strength to 1150 MPa and its tensile ductility to 36% after the HPHT treatment. Such strength-ductility synergy is attributed to the HPHT-induced formation of a hierarchically patterned microstructure with coherent interfaces, which promotes multiple deformation mechanisms, including dislocations, stacking faults, microbands and deformation twins, at multiple length scales. More importantly, the HPHT-induced microstructure helps relieve stress concentration at the interfaces, thereby arresting interfacial cracking commonly observed in traditional eutectic high entropy alloys. These findings suggest a new direction of research in employing HPHT techniques to help develop next generation structural materials.

Similar content being viewed by others

Introduction

Various industrial and advanced functional applications require materials with high strength and ductility. Unfortunately, conventional processing strategies usually attain high material strength at the expense of deteriorated ductility1,2,3, whilst develo** structures with substantial improvement of both strength and ductility is highly challenging. Recent successes in synthesizing superhard materials4,5,6 have made the high-pressure and high-temperature (HPHT) treatment7,8 promising to achieve extreme properties in materials. The combination of pressure and temperature offers the great prospect for altering the microstructure of structural materials that would permit overcoming the strength-ductility trade-off. Given the vast space of control parameters involved in the HPHT treatment and the often complex microstructural evolution under extreme pressures and temperatures9,10, it remains difficult to predict and interpret the mechanical behaviors of HPHT-treated structural materials, especially the abnormal kinetics and thermodynamics of non-equilibrium interfaces induced by the HPHT treatment11,12.

Eutectic high entropy alloys (EHEA) represent a promising class of multi-principal-element alloys featured by a hierarchical microstructure of dual-phase lamellae colonies, which offers great potential for achieving superior mechanical properties that are unmatched by conventional metallic materials13. However, the room-temperature brittleness and limited tensile ductility of these alloys hinder their usage in practical applications, despite a wide range of microstructural design strategies and associated processing techniques have been proposed14,15. Due to the prevalent interfacial structures in eutectic high entropy alloys, pronounced dislocation pile-ups are routinely developed in the vicinity of internal boundaries, where local stress concentration can emerge, leading to the onset of micro-cracking and catastrophic damage during mechanical straining16,17.

Here, we demonstrate that, with HPHT treatment in a self-designed hexahedron-anvil-press apparatus, the dual-phase lamellae structure frequently observed in eutectic high entropy alloys14,18 can be transformed to a hierarchically patterned microstructure with coherent interfaces. Tensile tests at ambient temperature demonstrate that the HPHT-treated specimens exhibit a high uniform tensile elongation (~36%) and greatly improved fracture strength (~1150 MPa), overcoming the typical brittle interfacial fracture mode in conventional eutectic high entropy alloys. Multiple deformation mechanisms, including dislocations, stacking faults, microbands and deformation twins, are observed at multiple length scales, as the applied strain increases. Isolated microcracks are uniformly distributed near the fracture surface in the HPHT-treated samples, in contrast to the catastrophic fracture in those without HPHT treatment. We further demonstrate that the HPHT treatment can be easily extended to other alloy systems for synergistic improvement of strength and ductility.

Results

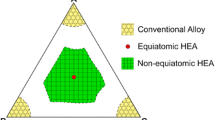

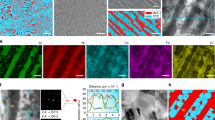

We used the homogenized Al0.7CoCrFeNi (molar ratio) alloy18 (hereafter termed Ho alloy) with a composition of Al14.8Co21.3Cr21.3Fe21.3Ni21.3 (at. %) and the typical dual-phase lamellae microstructure (Fig. 1a, b) as the precursor material for HPHT treatment. The corresponding EBSD phase map (Fig. 1c) clearly reveals the dual-phase lamellae consisting of alternating face-centered cubic (FCC) layers and body-centered cubic (BCC) layers. After HPHT treatment (Fig. 1f) at a pressure of 6 GPa and a temperature of 1473 K (more details see Methods), we confirmed that there is no change in the phase constitutions with X-ray diffraction (XRD) (Fig. 1g), where the corresponding peak positions of the HPHT-treated alloy are shifted slightly rightward due to densification. Notably, the HPHT-treated alloy exhibits a hierarchically patterned microstructure (Fig. 1h) consisting of hexagonal-like structural units (Fig. 1i). The corresponding EBSD phase map (Fig. 1j) reveals that the interior of each structural unit is composed of a mixture of FCC and BCC phases, while different units are interconnected by the FCC phase. The volume fractions of FCC and BCC phases in the HPHT-treated alloy were determined by EBSD to be ~69% and ~31%, nearly identical to those in the Ho alloy (~68% and ~32%). The elemental distribution maps of the HPHT-treated alloy (Fig. 1m–q) indicate that the FCC phase is relatively depleted in Al and Ni elements, with a composition of Al9Co22Cr28Fe24Ni17 (at. %), while the BCC phase is rich in Al and Ni, with a composition of Al30Co19Cr9Fe13Ni29 (at. %). Despite of the substantial change in microstructural pattern, the compositions of the FCC and BCC phases in the alloy before (Supplementary Fig. 1) and after HPHT treatment show almost no difference. Transmission electron microscopy (TEM) was used to better characterize the microstructures of the HPHT-treated alloy (Fig. 1k) and Ho alloy (Fig. 1d). The presence of superlattice spots in the selected area electron diffraction (SAED) patterns suggests an ordered B2 structure for the BCC phase. No other phases were detected in both alloys. A high-resolution TEM image of the interface region between the two phases (highlighted by the white dashed circle in Fig. 1k) in the HPHT-treated alloy reveals a coherent interface structure (Fig. 1l and Supplementary Fig. 3). The inset in Fig. 1l presents the corresponding fast Fourier transform (FFT) patterns, in which the diffraction spots with yellow and blue circles are the [100] crystal zone axis of the FCC and B2 phases, respectively. The orientation relationship between the two phases is confirmed to be (01-1)B2//(−111)FCC, which meets the classical Kurdjumov–Sachs (KS) relationshipFull size image