Abstract

The advanced patterning process is the basis of integration technology to realize the development of next-generation high-speed, low-power consumption devices. Recently, area-selective atomic layer deposition (AS-ALD), which allows the direct deposition of target materials on the desired area using a deposition barrier, has emerged as an alternative patterning process. However, the AS-ALD process remains challenging to use for the improvement of patterning resolution and selectivity. In this study, we report a superlattice-based AS-ALD (SAS-ALD) process using a two-dimensional (2D) MoS2-MoSe2 lateral superlattice as a pre-defining template. We achieved a minimum half pitch size of a sub-10 nm scale for the resulting AS-ALD on the 2D superlattice template by controlling the duration time of chemical vapor deposition (CVD) precursors. SAS-ALD introduces a mechanism that enables selectivity through the adsorption and diffusion processes of ALD precursors, distinctly different from conventional AS-ALD method. This technique facilitates selective deposition even on small pattern sizes and is compatible with the use of highly reactive precursors like trimethyl aluminum. Moreover, it allows for the selective deposition of a variety of materials, including Al2O3, HfO2, Ru, Te, and Sb2Se3.

Similar content being viewed by others

Introduction

Area-selective atomic layer deposition (AS-ALD) induces material deposition on the desired area by pre-defining a surface with different chemical activities1,2,3,4,5. The general procedure in preparing the pre-defined template for the conventional AS-ALD (CAS-ALD) is patterning a chemically inert barrier material using a top-down approach, which can prevent the chemisorption and subsequent reaction of ALD precursors on the substrates, leading to selective deposition on areas in which the barrier is absent1,2,3 (see Supplementary Note 1 for more details).

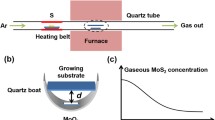

Interestingly, we observed AS-ALD on a two-dimensional (2D) MoS2-MoSe2 lateral superlattice as a patterning template. The 2D superlattice-based AS-ALD (SAS-ALD) is fundamentally different from the CAS-ALD. First, the length scale of the pattern fabricated by SAS-ALD can potentially overcome the fundamental resolution limit in the CAS-ALD. In the growth of 2D van der Waals materials, such as MoS2 and graphene, lateral growth can occur as a result of the nature of the crystal structure6,7,8,9,10. With this phenomenon, the lateral superlattice of 2D transition metal dichalcogenides (TMDs) has been demonstrated by supplying the precursors sequentially in the chemical vapor deposition (CVD) processFull size image

SEM images of initial nucleation step with 15 ALD cycles (a), and after merging step with 60 ALD cycles (b) on MoS2-MoSe2 lateral superlattice. Periodic Al2O3 deposition (bright region) can be seen in (a). c, d Molecular dynamics (MD) simulation map** images of the MoS2-MoSe2 lateral superlattice. The dotted lines are boundaries between MoS2 and MoSe2 regions. Z-height (c) and strain (d) periodically change in MoSe2 region. e Lattice constant map** data of the lateral superlattice by electron microscope pixel array detector (EMPAD) 4D STEM. f The xx and yy averaged strain density plot of the lateral superlattice cell in MD simulation. Yellow (red) region is MoS2 (MoSe2) density. g Schematics of three surfaces in the lateral superlattice; non-strained MoS2, tensile-strained MoSe2 crest, and compressive-strained MoSe2 valley. The molecules on the surfaces are trimethyl aluminum (TMA). h Schematics for process of SAS-ALD. Initial nucleation of Al2O3 periodically occurs in MoSe2 region, and the Al2O3 islands are merged.

a Schematics of TMA behaviors on 2D surface; adsorption, diffusion, desorption, and reaction. b Adsorption energy (green) and diffusion barrier (purple) plot of TMA molecule on MoS2 (filled dot) and MoSe2 (empty dot) surface with varying strain. Red, yellow, and gray dotted lines mean compressive-strained MoSe2, non-strained MoS2, and tensile-strained MoSe2, respectively. Visualizations of strain (c), diffusion rate (d), desorption rate (e), occupation with adsorption-desorption mode (f), occupation with diffusion mode (g), and collision (h) of TMA on MoS2-MoSe2 lateral superlattice cell at T = 443 K obtained by kinetic Monte Carlo (kMC) simulation. The red (blue) square and circle regions are MoSe2 valley (crest) regions. SEM images of Al2O3 SAS-ALD with changing ALD temperature (i) and width scale of MoS2 region (j). k Schematics of diffusion effect in SAS-ALD mechanism.

Characterization and controllability of SAS-ALD

Figure 2a shows the atomic force microscopy (AFM) images of the structure in which Al2O3 is selectively deposited on the MoS2-MoSe2 lateral superlattice grown on a Si/SiO2 (300 nm) substrate. We use TMA and H2O as ALD precursors, and the deposition temperature is 170 °C (see “Methods” for the details). Through three-dimensional tilted and top view images (Fig. 2a; top, middle), we confirmed that Al2O3 is selectively deposited with a 70 nm width and a 120 nm pitch size. The height profile (Fig. 2a; bottom) shows that the Al2O3 thickness is about 10 nm. The structure can also be identified with a tilted SEM image (Supplementary Fig. 3a). Figure 2b shows a cross-section high-angle-annular-dark-field scanning transmission electron microscopy (HAADF-STEM) image of the structure, which is similar to that shown in Fig. 2a but with a narrower width (~ 25 nm). Al2O3 is periodically and selectively deposited on the monolayer MoS2-MoSe2 lateral superlattice. A cross-section energy dispersive X-ray spectroscopy (EDS) map** image in Fig. 2c shows that aluminum atoms are detected on a selenium rich-region (right, MoSe2) but not on a sulfur-rich region (left, MoS2), which indicates that Al2O3 is selectively deposited on the MoSe2 region only. Additionally, the interface between Al2O3 and MoSe2 is clean, and the aluminum oxide exhibits valid bandgap values (see Supplementary Note 8).

Because of lateral growth, a crystallographic phenomenon exhibited by 2D materials, our SAS-ALD technique allows nanoscale control over the width of the patterning template (lateral superlattice) by adjusting the duration time of the gas-phase chalcogen precursors. Figure 2d–h shows line pattern controllability by adjusting the width of the superlattice. It is possible to form a uniform line pattern of Al2O3 spanning a few micrometers (Fig. 2d) and control the width and pitch size of the patterns (Fig. 2e–h). Figures 2e and 2f have the same pitch size (~57 nm) but different width sizes of Al2O3, 15 nm in Fig. 2e and 48 nm in Fig. 2f. Figures 2g and 2h have the same width size of Al2O3 (~ 45 nm) but different pitch sizes, 155 nm in Fig. 2g and 70 nm in Fig. 2h. In addition, Supplementary Fig. 3d shows patterns with the same pitch size (~96 nm) but with reversed width/space ratios (1:2 and 2:1). Supplementary Fig. 3e describes various width/space ratios ranging from 0.25 to 13. The minimum pitch size of the Al2O3 pattern is 19.7 nm (width ~ 16 nm), as shown in Supplementary Fig. 3f. Furthermore, in SAS-ALD, selectivity is maintained up to 15 nm of Al2O3 thickness (Supplementary Fig. 3b). From the above data, SAS-ALD can control various line patterns of target material with uniformity and high selectivity. The line patterns in SAS-ALD can be controlled diversely within a single flake (Fig. 2a–h), but the orientation between flakes is not aligned. Typically, as shown in Fig. 2i, lateral superlattices grown on a Si/SiO2 substrate have different directions, resulting in randomly oriented Al2O3 line patterns, as confirmed in the Fast Fourier Transform (FFT) image. In contrast, when utilizing a c-plane sapphire substrate, which facilitates the epitaxial growth of TMDs, the orientations of lateral superlattice flakes can be aligned, allowing for directional alignment of Al2O3 line patterns, as seen in Fig. 2j. Figure 2k presents AFM analysis for Fig. 2j, showing the selective deposition of 1 nm Al2O3 on the epitaxial lateral superlattice film. Lastly, the Al2O3 SAS-ALD is possible not only for the MoS2-MoSe2 lateral superlattice mentioned above but also for a WS2-WSe2 lateral superlattice. The WS2-WSe2 superlattice was confirmed through Raman spectroscopy and SEM images (Supplementary Fig. 19a–c), and the Al2O3 was selectively deposited on the WSe2 regions (Supplementary Fig. 19d).

Throughout Figs. 1, 2, we provide experimental evidence confirming the selective ALD occurring specifically on the MoSe2 region within the MoS2-MoSe2 lateral superlattice. This phenomenon of selectivity occurring on the basal planes of a 2D material with a non-dangling bond is totally different from the CAS-ALD, in which selectivity arises from the chemical reaction of the surface. In order to examine the mechanism of SAS-ALD, we analyzed the initial nucleation sites where deposition primarily occurs (Fig. 3) and performed relevant simulations (Fig. 4).

Initial nucleation sites in SAS-ALD

Figure 3h schematically represents a SAS-ALD process comprised of before ALD, initial nucleation, and after merging steps. Before ALD, periodic ripple structure forms within the MoSe2 region of the lateral superlattice, as shown in Supplementary Fig. 1e. Figure 3a shows a SEM image of a lateral superlattice with 15 Al2O3 ALD cycles, in which the light gray region shows Al2O3 deposited on MoSe2 and the dark region shows MoS2 without any deposition. Initial nucleation of Al2O3 forms islands, with each island nucleating periodically in the x-direction (under 20 nm in periodicity). When 60 ALD cycles are performed, the Al2O3 islands fully merge, forming a continuous line, as shown in Fig. 3b. Interestingly, Al2O3 not only selectively deposits on the MoSe2 region, but also exhibits preferential and periodic deposition at specific sites within the MoSe2. Supplementary Fig. 4a–d show the SAS-ALD process in a lateral superlattice with a relatively wider MoSe2 width. In this case, as shown in Supplementary Fig. 4a, large buckle structures of a few nanometers periodically form within the MoSe2 region. In addition, in Supplementary Fig. 4b, periodic Al2O3 deposition similar to Fig. 3a can be observed. A detailed explanation of the periodic deposition of Al2O3 is provided in Supplementary Note 3.

The periodic deposition observed in Fig. 3a and Supplementary Fig. 4b closely resemble the periodicity of ripples and buckles in the lateral superlattice. To understand the influence of these structures, we conducted Molecular Dynamics (MD) simulations and 4D STEM measurements. Figures 3c and 3d show the z-directional height and strain map** of the superlattice in MD simulation. In the z-height map** (Fig. 3c), while the MoS2 region remains relatively flat, the MoSe2 region is found to form repetitive ripples to relieve the compressive strain that results from coherent bonding with MoS2, which has a smaller lattice constant21. This ripple structure can be measured by AFM in Supplementary Fig. 1e. Importantly, in the strain map** (Fig. 3d), a periodic compressive-tensile lattice strain exists in the MoSe2 region, aligning with the ripple structure. The strain in Supplementary Fig. 5a shows the average atomic strain tensor on S and Se atoms. The Se atoms near the crest of ripples are under tensile strain, whereas Se atoms near the valley are under compressive strain. The density plot for population of the xx and yy average strain is described in Fig. 3f. From the density plot, we find that most strains on the MoS2 (yellow) are released, whereas the MoSe2 (red) gets both compressive and tensile strains. More information about strain map** by MD simulation is provided in Supplementary Note 4. In addition, the STEM data of lattice constant map** in Fig. 3e provide a rational explanation for the formation of the repetitive strain. In the x-directional lattice constant map** of Fig. 3e, white vertical line regions exist within MoSe2, indicating the presence of periodic compressive strain sites (reduction in the lattice constant) in MoSe2. Based on the MD simulations and STEM measurements, the MoS2-MoSe2 lateral superlattice can be divided into three regions as shown in Fig. 3g: non-strained MoS2, tensile-strained MoSe2 crest, and compressive-strained MoSe2 valley. Furthermore, the periodic initial deposition on MoSe2 in SAS-ALD is closely related to this repetitive strain in the MoSe2 region.

Mechanism of SAS-ALD

To begin with, we examine the possible interactions and behaviors of ALD precursors in the lateral superlattice, prior to investigating the relation between the SAS-ALD process and periodic strain in the MoSe2 region. Figure 4a schematically illustrates four representative processes (adsorption, diffusion, desorption, and dissociative reaction) of the ALD precursor (TMA) on the TMD. In CAS-ALD, a specific reaction can be considered as the key to selectivity, where the reaction rate between the ALD precursors and substrate is faster in deposition region than barrier region. However, our lateral superlattice, unlike conventional ALD substrates, lacks dangling bonds on the surface, rendering it chemically inert to direct reactions. Consequently, direct reactions are not expected to be the primary factor influencing selectivity. Indeed, we observe that the direct dissociative reaction of TMA to the TMD surface is highly endothermic on both areas of the superlattice surface (1.59 eV in MoS2, 2.03 eV in MoSe2, see Supplementary Table 1). In the reaction of H2O, the energies are more unstable (5.09 eV in MoS2, 5.22 eV in MoSe2). Additionally, the substantially higher endothermic reaction energy on MoSe2 than on MoS2 presents a contradiction to our SAS-ALD results.

Given these points, the influence of defects in the superlattice must also be examined. Defects in TMDs can disrupt the surface inactivity of ALD precursors, therefore requiring consideration of this factor as well. In our case, the CVD-grown TMDs inevitably contain defect sites, primarily chalcogen vacancies, as shown in the HAADF-STEM images in Supplementary Fig. 1d. However, we observe that the density of defects does not exhibit periodicity in the MoSe2 region, suggesting that defects are not the primary factors controlling selective deposition (Supplementary Note 2). Nevertheless, as defect sites can influence nucleation behavior, we included chalcogen vacancy sites in our investigation. Supplementary Table 1 provides a list of possible processes for ALD on the superlattice, along with the lowest energy configurations obtained for each process. We found that TMAs adsorb to the chalcogen top sites with adsorption energies of −0.67 and −0.66 eV on MoSe2 and MoS2 surfaces, respectively. On chalcogen vacancies, the binding is significantly weakened, measuring −0.48 eV for both TMD surfaces. This indicates that vacancies do not exhibit a stronger affinity for TMA adsorption. The adsorption of H2O is relatively weak compared to TMA on the chalcogen top sites (−0.15 eV on MoS2 and MoSe2) and the chalcogen defect sites (−0.25 eV on Vs and −0.30 on VSe). However, we found that H2O adsorption on pre-adsorbed TMA exhibits stronger adsorption energies (−0.43 eV on MoSe2 and MoS2, see Supplementary Fig. 11). Additionally, the consecutive reaction of the TMA-H2O complex shows a small activation energy (~ 0.34 eV) and a highly endothermic reaction energy (~ −0.94 eV), implying rapid reaction once such a complex form. This means that the H2O will follow the adsorption selectivity of TMA, not determining selective deposition itself. In terms of dissociative reactions between ALD precursors and chalcogen vacancy sites, the reaction energy of TMA is 1.09 eV on VS and 1.38 eV on VSe (Supplementary Table 1). In the case of H2O, the reaction energy is 1.22 eV on VS and 1.29 eV on VSe. All of the dissociative reactions exhibit a very high energy level (1 ~ 2 eV), making them hard to occur easily. Importantly, even the dissociative reaction of ALD precursors at chalcogen vacancy sites is more favorable in MoS2 region than MoSe2 region, which contradicts our SAS-ALD results. Therefore, considering the distribution of defects and the adsorption and reaction energies of the ALD precursors at the chalcogen vacancy sites, we can rule out the possibility that defects induce selective deposition in SAS-ALD. More detailed explanation of defect and reaction effects is provided in Supplementary Note 5.

In contrast to CAS-ALD, the reactions of ALD precursors on the substrate or any defect sites are not the origin of the selectivity in SAS-ALD. Therefore, we need to analyze other behaviors of the precursors (Fig. 4a), and the first one is adsorption. In Fig. 3, we confirmed that the SAS-ALD is significantly associated with the periodic strain in the MoSe2 region. We thus analyze the adsorption energy of TMA with respect to TMD’s lattice straining through DFT calculations. The green square dots in Fig. 4b represent the adsorption energy of TMA molecules as a function of strain on MoS2 (filled square) and MoSe2 (empty square). In both MoS2 and MoSe2, the adsorption energy of TMA stabilizes with increasing compressive strain. Supplementary Fig. 9 illustrates the TMA adsorption energy on TMD surface with respect to the direction of strain, confirming the stability of adsorption with compressive strain. When considering the three areas in Fig. 3g (MoS2 flat, MoSe2 crest, and MoSe2 valley), the adsorption energy of TMA in the compressed MoSe2 valley region (red dotted square in Fig. 4b) is more than 60 meV stable than the other two areas. In addition, in the MoSe2 valley, the adsorption energy of TMA can be further stabilized with curvature. Supplementary Fig. 10 shows the variation of TMA adsorption energy in MoSe2 planar and concave cell, confirming a decrease in adsorption energy in the concave valley. In other words, it can be observed that TMAs bind more strongly to the sites in the compressively strained MoSe2 valley than in other regions of the lateral superlattice. This phenomenon is attributed to the fact that the interaction of TMA with the TMD is dominantly the van der Waals interaction, with denser/concave surfaces producing stronger interaction. As such, the trends in adsorption energies holds for other AS-ALD materials, with the adsorption of the precursors being most stable in the compressed MoSe2 valley region (Supplementary Figs. 12 and 13. See more details in Supplementary Note 6).

Through the above data, it was found that the TMA adsorption energy is lowest in the compressed MoSe2 valley region. However, relying solely on adsorption energy to explain the high selectivity of SAS-ALD may not provide a complete picture. As shown in Supplementary Fig. 15, when ALD is performed on a single MoS2 or MoSe2 surface, the coverage of Al2O3 is higher on MoSe2 than MoS2 due to the difference in TMA adsorption energy. However, Al2O3 clearly deposits on the single MoS2 flake. To explain the high selectivity of SAS-ALD, additional analysis of TMA diffusion was conducted. The purple triangle dot in Fig. 4b shows the TMA diffusion barrier on MoS2 (filled triangle) and MoSe2 (empty triangle) surface as obtained by Nudged Elastic Band (NEB) calculations. Similar to adsorption energy, the diffusion barrier of TMA tends to decrease with compressive strain on the TMD surface, and among the three regions in Fig. 3g, the compressed MoSe2 valley shows the lowest diffusion barrier of TMA ( ~ 0.09 eV, red dotted triangle in Fig. 4b). In other words, TMA is expected to have the most stable adsorption and also the lowest diffusion barrier in the MoSe2 valley area, making the statistical presence of precursors higher in this region.

While it is apparent that DFT-calculated energies are in good agreement with experimental observations, one may point out that the changes in adsorption and diffusion energies are relatively small. However, even minor energetic differences can have profound implications when examining kinetics on larger spatial and temporal scales. To quantify the extent of these differences, we implemented a straightforward kinetic Monte Carlo (kMC) simulation where TMAs adsorb/desorb, and diffuse on a small lateral superlattice generated via molecular dynamics. Figure 4c shows the xx, yy, and zz strain tensor average map** of our simulation cell, showing periodic strain distributions in the MoSe2 regions. The red square region represents the MoSe2 valley under compressive strain (orange). The cell configuration and z-coordinate (z-height map**) for the lateral superlattice can be seen in Supplementary Fig. 16a and b. Employing linear regression, we derived estimates for the diffusion (Fig. 4d) and desorption (Fig. 4e) rates of TMA across all surface sites on the lateral superlattice cell at T = 443 K. Surprisingly, as observed in Fig. 4d, the diffusion rate of TMA is highest in the MoSe2 valley (red circle), approximately three times faster than in the MoSe2 crest (blue circle). In Fig. 4e, the desorption rate of TMA is the slowest in the MoSe2 valley (red circle), with the MoS2 region exhibiting desorption roughly ten times faster than the MoSe2 region. Supplementary Fig. 16c–e provide diffusion and desorption rates, as well as rate constants at T = 383, 413, 443, and 474 K. It can be observed that as the temperature increases, both diffusion and desorption rates generally become faster. Nevertheless, at all temperatures, it is evident that TMA diffusion is fastest and desorption is slowest in the MoSe2 valley area, suggesting a strong direct indication that TMA is more abundant and likely to collide more frequently in the MoSe2 valley region. Using our estimated rate constants, we conducted kMC simulations of a TMA pulse. Figure 4f and Fig. 4g present occupation heatmaps at T = 443 K, the normalized residence time of TMA molecules at specific sites by total simulation time. Figure 4f represents the adsorption-desorption mode, while Fig. 4g is the diffusion-only mode for TMA. Importantly, both of these occupation map**s confirm the long residence of TMA in the MoSe2 valley area (red circle). In addition to TMA occupation, we also examined the frequency of collisions between TMA molecules at T = 443 K (Fig. 4h). The collision heatmap visualizes the number of TMA collisions occurring at each site during simulation, normalized by the total collision number. Since the diffusion of TMA molecules on the TMD surface is very rapid, the collision frequency of TMA can also serve as a good estimate of nucleation in SAS-ALD, given the structural similarities between the TMAs and the reactive single Al(OH)n(CH3)3-n intermediates. As evident in Fig. 4h, the MoSe2 valley region experiences the highest frequency of TMA collisions. In summary, the MoSe2 valley region is predicted to have the highest TMA presence in terms of adsorption, diffusion, and desorption. Based on this calculation, the kMC simulations show the longest TMA residence and highest collision rate on the compressed MoSe2 valley area.

The control experiments also provide evidence of the significant roles played by TMA’s adsorption and diffusion in the SAS-ALD process. Figure 4i shows SEM images depicting the trends in Al2O3 AS-ALD with varying ALD temperatures. When the temperature is relatively high (200 and 170 °C), undesired deposition does not occur on the MoS2 region (black area). However, as the temperature decreases (140 and 110 °C), Al2O3 deposition occurs on the MoS2 region as well. In other words, when the temperature is low, the selectivity in SAS-ALD diminishes. This phenomenon is expected to occur because as the temperature decreases, the distance that TMAs can move is reduced, resulting in many TMA molecules being present on the MoS2 region as well. In particular, as the temperature decreases, the coverage of TMA on the whole superlattice cell increases (Supplementary Fig. 17) and the collision rate of TMA on the cell also increases (Supplementary Fig. 18). This suggests that while TMA diffusion is quite fast, at lower temperatures, a significant number of TMA molecules exist on the MoS2 region and form nucleation before desorbing or reaching the MoSe2 valley area, where more nucleates will be present. As a result, at lower ALD temperatures, the higher presence of TMA on the MoS2 region, along with an increased frequency of collisions, leads to many undesired depositions. Such an explanation is also backed by the fact that the MoS2 width also shows strong correlation to undesired deposition. The MoS2 width is considered the distance over which TMA should diffuse for AS-ALD, and as the width of MoS2 increases, more TMAs fail to arrive at the MoSe2 valley, leading to increased undesired deposition on MoS2 region, as shown in Fig. 4j.

Our findings confirm that the SAS-ALD mechanism can be represented by a complex interplay of various interactions, such as adsorption, diffusion, and desorption of ALD precursors on 2D TMD surfaces, with the compressed MoSe2 valley region identified as the primary site for deposition, as shown in Fig. 3h. The selectivity inherent in SAS-ALD cannot be attributed to reactions between TMA and the 2D TMD surfaces or to the presence of chalcogen vacancy sites (Supplementary Note 5). Instead, the selectivity is originated by the energetically most stable adsorption (Fig. 4b) and the slowest desorption rates (Fig. 4e) in the MoSe2 valley region, leading to the highest concentration of TMA. With respect to diffusion, the MoSe2 valley presents the lowest surface diffusion barrier for TMA, as shown in Fig. 4b, corresponding with the fastest diffusion rates in this region, as depicted in Fig. 4d. The kMC simulations support this, suggesting that TMA’s residence time is longest in the MoSe2 valley, as detailed in Figs. 4f and 4g, and collisions are most frequent in this area, as indicated in Fig. 4h. This evidence highlights AS-ALD mechanism within SAS-ALD, wherein diffusion plays a crucial role, as represented schematically in Fig. 4k.