Abstract

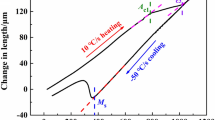

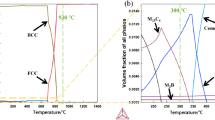

Mechanical properties of quenching, intercritical quenching and tempering (QLT) treated steel containing Ni of 9% were evaluated from specimens subject to various tempering temperatures. The detailed microstructures of steel containing Ni of 9% at different tempering temperatures were observed by optical microscope (OM) and trans- mission electron microscope (TEM). The volume fraction of austenite was estimated by XRD. The results show that high strength and cryogenic toughness of steel containing Ni of 9% are obtained when the tempering temperature are between 540 and 580 °C. The microstrueture keeps the dual phase lamellar structure after the intercritical quenching and there is cementite created in the Ni-rich constituents when tempering temperature is 540 °C. When tempering temperatures are between 560 and 580 °C, the reversed austenites (γ′) grow up and the dual phase lamellar structure is not clear. The γ′ becomes instable at 600 °C. When tempered at temperature ranging from 500 to 520 °C, the increase of dislocation density in the lamellar matrix makes both tensile strength and yield strength decrease. When tempered at 540 °C and higher temperature, the yield-strength decreases continuously because the C and alloying elements in the matrix are absorbed by the cementite and the γ′, so the yield ratio is decreased by the γ′. There are two toughness mechanisms at different tempering temperatures. One is that the precipitation of cementite absorbs the carbon in the steel which plays a major role in improving cryogenic toughness at lower temperature. Another is that the γ′ and the purified matrix become major role at higher tempering temperature. When the tempering temperature is 600 °C, the stability of γ′ is decreased quickly, even the transformation takes place at room temperature, which results in a sharp decrease of Charpy-V impact energy at 77 K. The tempering temperature range is enlarged by the special distribution of cementite and the lamellar structure.

Similar content being viewed by others

References

XIAN Zhi-wei, XIE Zhen. World LNG Industry and Its Development [J]. Natural Gas and Oil, 2005, 23(2): 6.

Ghouri S S. Global LNG Market Outlook-Challenges and Opportunities [C] // 2005 International Petroleum Technology Conference Proceedings. Doha; [s. n. ], 2005: 679.

Sophia Ruester, The Prospects for Liquefied Natural Gas Development in the US [J]. Energy Policy, 2008, 36(8): 3160.

QIAO Guo-fa, LI Yu-xing. The Present Situation and Future of Liquefied Natural Gas Industry in China [J]. Oil and Gas Storage and Transportation, 2005, 24(3): 1.

Strife J R, Passoja D E. The Effect of Heat Treatment on Microstructure and Cryogenic Fracture Properties in 5 Ni and 9 Ni Steel [J]. Metallurgical Transactions, 1980, 11A(8): 1341.

Syn Choi K, ** Sungho, Morris J W. Cryogenic Fracture Toughness of 9Ni Steel Enhanced Through Grain Refinement [J]. Metallurgical Transactions, 1976, 7A(11): 1827.

Fultz B, Kim J I, Morris J W. The Chemical Composition of Precipitated Austenite in 9Ni Steel [J]. Metallurgical Transactions, 1986, 17A(6): 967.

ZHAO **-qing, PAN Tao, WANG Qing-feng. Effect of Intercritical Quenching on Reversed Austenite Formation and Cryogenic Toughness in QLT-Processed 9%Ni Steel [J]. Journal of Iron and Steel Research, International, 2007, 14 (Supplement): 240.

Nobuo Nakada, Junaidi Syarif, Toshihiro Tsuchiyama. Improvement of Strength-Ductility Balance by Copper Addition in 9 % Ni Steels [J]. Materials Science and Engineering, 2004, 374A: 137.

Fultz B, Kim J I. The Stability of Precipitated Austenite and the Toughness of 9Ni Steel [J]. Metallurgical Transactions, 1985, 16A(11): 2237.

Syn C K, Fultz B, Morris J W. Mechanical Stability of Retained Austenite in Tempered 9Ni Steel [J]. Metallurgical Transactions, 1978, 9A(1): 1635.

Kim J I, Syn C K, Morris Jr J W. Microstructural Sources of Toughness in QLT-Treated 5. 5Ni Cryogenic Steel [J]. Metallurgical Transactions, 1983, 14A(1): 93.

WENG Yu-qing. Ultrafine Grained Steel [M]. Bei**g: Metallurgical Industry Press, 2003 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National High Technology Research and Development Program of China (2007AA03Z506)

Rights and permissions

About this article

Cite this article

Zhao, Xq., Pan, T., Wang, Qf. et al. Effect of Tempering Temperature on Microstrueture and Mechanical Properties of Steel Containing Ni of 9 %. J. Iron Steel Res. Int. 18, 47–51 (2011). https://doi.org/10.1016/S1006-706X(11)60064-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(11)60064-2