Abstract

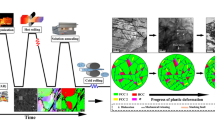

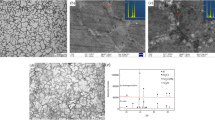

The effects of hot-rolling (HR), cold-rolling (CR), and HR + CR followed by aging on the microstructure and mechanical properties of the medium-entropy alloy (MEA) Ni43.4Co25.3Cr25.3Al3Ti3 were investigated. The geometrically-necessary dislocation (GND) density increased with increasing cold rolling reduction to 1.8–2.4 × 1014 m−2, which is eight times the 2.9 × 1013 m−2 found in the as-hot-rolled MEA. Higher dislocation density before aging led to a finer, higher volume fraction of L12 nanoparticles as well as finer grains, which resulted from both accelerated nucleation on dislocations and, possibly, accelerated pipe diffusion via the dislocations. The aged CR MEA exhibited an excellent strength-ductility combination (yield strength ~ 1414 MPa, ultimate tensile strength ~ 1605 MPa, elongation ~ 15%) with precipitate strengthening accounting for 26% of the yield strength, which was better than the mechanical properties of the aged HR MEA (yield strength ~ 897 MPa, ultimate tensile strength ~ 1217 MPa, elongation ~ 32.3%). A combination of hot-rolling and cold-rolling also leads to a good strength-ductility combination (yield strength ~ 1501 MPa, ultimate tensile strength ~ 1651 MPa, elongation ~ 20.8%), with grain boundary strengthening and precipitate strengthening accounting for 62% and 25% of the yield strength, respectively. Substantial partitioning and fluctuations of the principle atoms were observed in as-CR sample due to dislocations interacting with the alloying atoms, i.e. several nano-scaled regions were enriched in Ni, Al, and Ti, and depleted in Cr and Co. In addition, Al and Ti have more substantial local fluctuations in composition than Ni, Co, and Co.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings can not be shared at this time as the data also forms part of an ongoing study.

References

Y.Y. Zhao, T.G. Nieh, Correlation between lattice distortion and friction stress in Ni-based equiatomic alloys. Intermetallics 86, 45–50 (2017)

J.B. Seol, J.W. Bae, Z.M. Li, J.C. Han, J.G. Kim, D. Raabe, H.S. Kim, Boron doped ultrastrong and ductile high-entropy alloys. Acta Mater. 151, 366–376 (2018)

I. Baker, Interstitials in f.c.c. high entropy alloys. Metals 10(5), 695–715 (2020)

I. Baker, F.L. Meng, M. Wu, A. Brandenberg, Recrystallization of a novel two-phase FeNiMnAlCr high entropy alloy. J. Alloys Compd. 656, 458–464 (2016)

H.L. Peng, L. Hu, L.J. Li, J.X. Gao, Q. Zhang, On the correlation between L12 nanoparticles and mechanical properties of (NiCo)52+2x(AlTi)4+2xFe29-4xCr15 (x=0-4) high-entropy alloys. J. Alloys Compd. 817, 152750 (2020)

M.V. Klimova, D.G. Shaysultanov, S.V. Zherebtsov, N.D. Stepanov, Effect of second phase particles on mechanical properties and grain growth in a CoCrFeMnNi high entropy alloy. Mater. Sci. Eng. A 748, 228–235 (2019)

Z.W. Wang, A. Genc, I. Baker, Direct versus indirect particle strengthening in a strong, ductile FeNiMnAlTi high entropy alloy. Mater. Charact. 132, 156–161 (2017)

S. Shukla, R.S. Mishra, Excellent high cyclic fatigue properties of a novel ultrafine-grained medium entropy alloy. Mater. Sci. Eng. A 779, 139122 (2020)

H.L. Peng, I. Baker, L. Hu, L.J. Li, Superior strength-ductility synergy in a novel tailored nanoparticles-strengthened medium-entropy alloy. Scr. Mater. 207, 114278 (2022)

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, Z.P. Lu, A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 102, 187–196 (2016)

X.L. Huang, L.P. Huang, H.L. Peng, Y. Liu, B. Liu, S. Li, Enhancing strength-ductility synergy in a casting non-equiatomic NiCoCr-based high-entropy alloy by Al and Ti combination addition. Scr. Mater. 200, 113898 (2021)

T. Rieger, J.M. Joubert, M. Laurent-Brocq, L. Perrière, I. Guillot, J.P. Couzinié, Study of the FCC+L12 two-phase region in complex concentrated alloys based on the Al–Co–Cr–Fe–Ni–Ti system. Materialia 14, 100905 (2020)

H.L. Peng, Y.Y. Yi, W.P. Fang, L. Hu, I. Baker, L.J. Li, B.B. Luo, Optimization of the microstructure and mechanical properties of electron beam welded high-strength medium-entropy alloy (NiCoCr)94Al3Ti3. Intermetallics 141, 107439 (2022)

H.L. Peng, I. Baker, Y.Y. Yi, L. Hu, W.P. Fang, L.J. Li, B.B. Luo, Z.Y. Luo, Dissimilar electron beam welding of the medium-entropy alloy (NiCoCr)94Al3Ti3 to 304 stainless steel. Scr. Mater. 214, 114659 (2022)

T. Yang, Y.L. Zhao, L. Fan, J. Wei, J.H. Luan, W.H. Liu, C. Wang, Z.B. Jiao, J.J. Kai, C.T. Liu, Control of nanoscale precipitation and elimination of intermediate-temperature embrittlement in multicomponent high-entropy alloys. Acta Mater. 189, 47–59 (2020)

Z.W. Wang, I. Baker, Effects of annealing and thermo-mechanical treatment on the microstructures and mechanical properties of a carbon-doped FeNiMnAl multi-component alloy. Mater. Sci. Eng. A 693, 101–110 (2017)

B. Gao, Q.Q. Lai, Y. Cao, R. Hu, L.R. **ao, Z.Y. Pan, N.N. Liang, Y.S. Li, G. Sha, M.P. Liu, H. Zhou, X.L. Wu, Y.T. Zhu, Ultrastrong low-carbon nanosteel produced by heterostructure and interstitial mediated warm rolling. Sci. Adv. 6(39), 8169–8192 (2020)

M. Wu, C. Yang, M. Kuijer, I. Baker, Enhanced mechanical properties of carbon-doped FeNiMnAlCr high entropy alloy via hot-rolling. Mater. Charact. 158, 109983 (2019)

Z.W. Wang, I. Baker, Z.H. Cai, S. Chen, J.D. Poplasky, W. Guo, The effect of interstitial carbon on the mechanical properties and dislocation substructure evolution in Fe40.4Ni11.3Mn34.8Al7.5Cr6 high entropy alloys. Acta Mater. 120, 228–239 (2016).

K.T. Park, Tensile deformation of low-density Fe–Mn–Al–C austenitic steels at ambient temperature. Scr. Mater. 68(6), 375–379 (2013)

J.W. Cahn, Nucleation on dislocations. Acta Metall. 5(3), 169–172 (1957)

S.P. Chen, N.C.W. Kuijpers, S.V.D. Zwaag, Effect of microsegregation and dislocations on the nucleation kinetics of precipitation in aluminium alloy AA3003. Mater. Sci. Eng. A 341, 296–306 (2003)

G. Trotter, G. Rayner, I. Baker, P.R. Munroe, Accelerated precipitation in the AFA stainless steel Fe–20Cr–30Ni–2Nb–5Al via cold working. Intermetallics 53, 120–128 (2014)

B. Dutta, E.J. Palmiere, C.M. Sellars, Modelling the kinetics of strain induced precipitation in Nb microalloyed steels. Acta Mater. 49(5), 785–794 (2001)

V.L. Niranjani, K.C.H. Kumar, V.S. Sarma, Development of high strength Al–Mg–Si AA6061 alloy through cold rolling and ageing. Mater. Sci. Eng. A 515(1–2), 169–174 (2009)

K.S. Raju, V.S. Sarma, A. Kauffmann, Z. Hegedűs, J. Gubicza, M. Peterlechner, J. Freudenberger, G. Wilde, High strength and ductile ultrafine-grained Cu–Ag alloy through bimodal grain size, dislocation density and solute distribution. Acta Mater. 61(1), 228–238 (2013)

H.L. Peng, L. Hu, J.F. Chen, S.M. Huang, L.J. Li, Y.Y. Yi, F. Zhou, W.P. Fang, I. Baker, Microstructures and deformation mechanisms of the medium-entropy alloy (NiCoCr)76(Ni6AlTi)3. Mater. Sci. Eng. A 849, 143449 (2022)

Y.Y. Zhao, H.W. Chen, Z.P. Lu, T.G. Nieh, Thermal stability and coarsening of coherent particles in a precipitation-hardened (NiCoFeCr)94Ti2Al4 high-entropy alloy. Acta Mater. 147, 184–194 (2018)

Z.W. Wang, I. Baker, W. Guo, J.D. Poplawsky, The effect of carbon on the microstructures, mechanical properties, and deformation mechanisms of thermo-mechanically treated Fe40.4Ni11.3Mn34.8Al7.5Cr6 high entropy alloys. Acta Mater. 126, 346–360 (2017).

M. Calcagnotto, D. Ponge, E. Demir, D. Raabe, Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 527(10–11), 2738–2746 (2010)

D.D. Zhang, J.Y. Zhang, J. Kuang, G. Liu, J. Sun, Superior strength-ductility synergy and strain hardenability of Al/Ta co-doped NiCoCr twinned medium entropy alloy for cryogenic applications. Acta Mater. 220, 117288 (2021)

O. Waseda, R.G.A. Veiga, J. Morthomas, P. Chantrenne, C.S. Becquart, F. Ribeiro, A. Jelea, H. Goldenstein, M. Perez, Formation of carbon Cottrell atmospheres and their effect on the stress field around an edge dislocation. Scr. Mater. 129, 16–19 (2017)

R. Rementeria, J.D. Poplawsky, M.M. Aranda, W. Guo, J.A. Jimenez, C. Garcia-Mateo, F.G. Caballero, Carbon concentration measurements by atom probe tomography in the ferritic phase of high-silicon steels. Acta Mater. 125, 359–368 (2017)

D. Blavette, E. Cadel, A. Fraczkiewicz, A. Menand, Three-dimensional atomic-scale imaging of impurity segregation to line defects. Science 286, 2317–2319 (1999)

E. Pereloma, H. Beladi, L.C. Zhang, I. Timokhina, Understanding the behavior of advanced high-strength steels using atom probe tomography. Metall. Mater. Trans. A 43(11), 3958–3971 (2011)

K. Hoummada, G. Tellouche, I. Blum, A. Portavoce, M. Descoins, D. Mangelinck, Direct observation of Ni decorated dislocation loops within As+-implanted silicon and arsenic clustering in Ni silicide contact. Microelectron. Eng. 107, 184–189 (2013)

I. Timokhina, H. Beladi, X.Y. **ong, P.D. Hodgson, On the low temperature strain aging of bainite in the TRIP steel. Metall. Mater. Trans. A 44(11), 5177–5191 (2013)

P. Kontis, Z.M. Li, D.M. Collins, J. Cormier, D. Raabe, B. Gault, The effect of chromium and cobalt segregation at dislocations on nickel-based superalloys. Scr. Mater. 145, 76–80 (2018)

L. Lilensten, P. Kürnsteiner, J.R. Mianroodi, A. Cervellon, J. Moverare, M. Segersäll, S. Antonov, P. Kontis, Segregation of solutes at dislocations: a new alloy design parameter for advanced superalloys. In Superalloys 2020: Proceedings of the 14th International Symposium on Superalloys (Springer, Berlin, 2020), pp. 41–51.

J. Wilde, A. Cerezo, G.D.W. Smith, Three-dimensional atomic-scale map** of a cottrell atmosphere around a dislocation in iron. Scr. Mater. 43, 39–48 (2000)

G.D.W. Smith, D. Hudson, P.D. Styman, C.A. Williams, Studies of dislocations by field ion microscopy and atom probe tomography. Philos. Mag. 93(28–30), 3726–3740 (2013)

J.S. Zhang, Strength of Materials (Harbin Institute of Technology Press, Harbin, 2014)

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1–93 (2014)

B. Weiss, R. Stickler, Phase instabilities during high temperature exposure of 316 austenitic stainless steel. Metall. Trans. 3, 851–866 (1972)

J. Pelleg, Diffusion in Dislocations, Diffusion in Ceramics (Springer, Cham, 2016), pp.87–94

B. Dutta, E.J. Palmiere, C.M. Sellars, Modelling the kinetics of strain induced precipitation in Nb microalloyed steels. Acta Mater. 49, 785–794 (2001)

S.G. Hong, K.B. Kang, C.G. Park, Strain-induced precipitation of NbC in Nb and Nb-Ti microalloyed HSLA steels. Scr. Mater. 46, 163–168 (2002)

O. Kwon, A.J. Deardo, Interactions between recrystallization and precipitation in hot-deformed microalloyed steels. Acta Metall. Mater. 39(4), 529–538 (1991)

W.M. Rainforth, M.P. Black, R.L. Higginson, E.J. Palmiere, C.M. Sellars, I. Prabst, P. Warbichler, F. Hofer, Precipitation of NbC in a model austenitic steel. Acta Mater. 50, 735–747 (2002)

Z.Q. Wang, X.P. Mao, Z.G. Yang, X.J. Sun, Q.L. Yong, Z.D. Li, Y.Q. Weng, Strain-induced precipitation in a Ti micro-alloyed HSLA steel. Mater. Sci. Eng. A 529, 459–467 (2011)

B. Dutta, E. Valdes, C.M. Sellars, Mechanism and kinetics of strain induced precipitation of Nb(C, N) in austenite. Acta Metall. Mater. 40(4), 653–662 (1992)

Y.Q. Weng, Y. Gan, H. Dong, Advanced steels: the recent scenario in steel science and technology (Springer, Berlin, 2011)

T. Yang, Y.L. Zhao, J.H. Luan, B. Han, J. Wei, J.J. Kai, C.T. Liu, Nanoparticles-strengthened high-entropy alloys for cryogenic applications showing an exceptional strength-ductility synergy. Scr. Mater. 164, 30–35 (2019)

L. Hu, H.L. Peng, I. Baker, L.J. Li, W.P. Zhang, T. Ngai, Characterization of high-strength high-nitrogen austenitic stainless steel synthesized from nitrided powders by spark plasma sintering. Mater. Charact. 152, 76–84 (2019)

S. Yoshida, T. Bhattacharjee, Y. Bai, N. Tsuji, Friction stress and Hall-Petch relationship in CoCrNi equi-atomic medium entropy alloy processed by severe plastic deformation and subsequent annealing. Scr. Mater. 134, 33–36 (2017)

L. Fan, T. Yang, Y. Zhao, J. Luan, G. Zhou, H. Wang, Z.B. Jiao, C.T. Liu, Ultrahigh strength and ductility in newly developed materials with coherent nanolamellar architectures. Nat. Commun. 11, 6240 (2020)

Y.L. Zhao, T. Yang, Y. Tong, J. Wang, J.H. Luan, Z.B. Jiao, D. Chen, Y. Yang, A. Hu, C.T. Liu, J.J. Kai, Heterogeneous precipitation behavior and stacking-fault-mediated deformation in a CoCrNi-based medium-entropy alloy. Acta Mater. 138, 72–82 (2017)

D.D. Zhang, H. Wang, J.Y. Zhang, H. Xue, G. Liu, J. Sun, Achieving excellent strength-ductility synergy in twinned NiCoCr medium-entropy alloy via Al/Ta co-do**. J. Mater. Sci. Technol. 87, 184–195 (2021)

B. Gwalani, V. Soni, M. Lee, S.A. Mantri, Y. Ren, R. Banerjee, Optimizing the coupled effects of Hall-Petch and precipitation strengthening in a Al 0.3 CoCrFeNi high entropy alloy. Mater. Des. 121, 254–260 (2017)

H.L. Peng, L. Hu, L.J. Li, W.P. Zhang, Ripening of L12 nanoparticles and their effects on mechanical properties of Ni28Co28Fe21Cr15Al4Ti4 high-entropy alloys. Mater. Sci. Eng. A 772, 138803 (2020)

K.S. Ming, X.F. Bi, J. Wang, Realizing strength-ductility combination of coarse-grained Al0.2Co1.5CrFeNi1.5Ti0.3 alloy via nano-sized, coherent precipitates. Int. J. Plast. 100, 177–191 (2018)

Z. Wu, Y.F. Gao, H. Bei, Single crystal plastic behavior of a single-phase, face-center-cubic-structured, equiatomic FeNiCrCo alloy. Scr. Mater. 109, 108–112 (2015)

Acknowledgements

The authors acknowledge financial support from the Guangdong Basic and Applied Basic Research Foundation (2022A1515110390), Guangzhou Basic and Applied Basic Research Foundation (2023A04J0994), Science and Technology Planning Project of Guangdong Province (No. 2022B1212050001), GDAS′ Project of Science and Technology Development (2022GDASZH-2022010107), and Ministry of Science and Technology of the People’s Republic of China (2020YFE0205300).

Funding

Funding was provided by Guangdong Basic and Applied Basic Research Foundation (2022A1515110390), Guangzhou Basic and Applied Basic Research Foundation (2023A04J0994), Science and Technology Planning Project of Guangdong Province (2022B1212050001), GDAS′ Project of Science and Technology Development (2022GDASZH-2022010107), and Ministry of Science and Technology of the People’s Republic of China (2020YFE0205300).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Peng, H., Hu, L. & Baker, I. Effects of Thermo-mechanical Treatment on the Microstructures and Mechanical Properties of a Medium-Entropy Alloy. High Entropy Alloys & Materials 1, 295–311 (2023). https://doi.org/10.1007/s44210-023-00018-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s44210-023-00018-8